Checkered plate roller and using method thereof

A patterned plate and pattern technology, which is applied in the direction of rolls, metal rolling, metal rolling, etc., can solve the problems of small number of times of use of a single engraved roll, easy chipping of pattern grooves, and cracks, etc., to reduce pattern pressure grooves Edge chipping, reduction of rolling force, and the effects of optimizing parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A checkered plate roll of the present embodiment has a roll body diameter of 700 mm, a roll body length of 1830 mm, and a pattern embossing groove engraved within a middle width of the roll body surface of the roll within a range of 1630 mm.

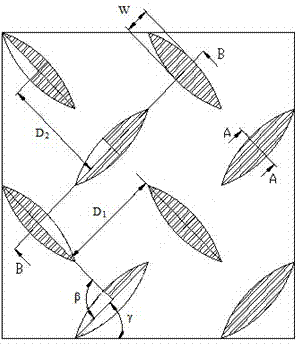

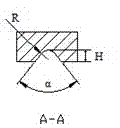

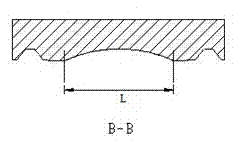

[0031] The pattern embossing groove on the surface of the roll is lentil-shaped, and the pattern pressed on the steel plate is lentil-shaped. The notch edge of the pattern embossing groove is composed of two symmetrical circular arcs. The length L of the notch of the pattern embossing groove is 35mm, and the width W of the notch is 5mm. The angle α between the two groove side surfaces inside the groove is 80 degrees, and the bottom of the two groove sides is smoothly connected by an arc with a radius R of 2.5mm. The maximum depth of the groove bottom of the pattern pressure groove is H 1 is 4mm.

[0032] The lentil-shaped embossing grooves on the surface of the roll are set horizontally and vertically alternately, and the distanc...

Embodiment 2

[0034] A checkered plate roll of the present embodiment has a roll body diameter of 637 mm, a roll body length of 1830 mm, and a pattern embossing groove engraved within a middle width of the roll body surface of the roll within a range of 1630 mm.

[0035] The pattern embossing groove on the surface of the roll is lentil-shaped, and the pattern pressed on the steel plate is lentil-shaped. The notch edge of the pattern pressing groove is composed of two symmetrical arcs. The length L of the pattern pressing groove is 30mm, and the width W of the notch is 10mm. The groove bottom of the pattern pressing groove along the length direction is arc-shaped. The angle α between the two groove side surfaces inside the pressure groove is 82.5 degrees, the bottom of the two groove sides is smoothly connected by an arc with a radius R of 3.5mm, and the maximum depth H1 of the groove bottom of the pattern pressure groove is 4.5mm .

[0036] The lentil-shaped embossing grooves on the surfac...

Embodiment 3

[0038] A method for using a checkered plate roll in this embodiment includes the following process steps,

[0039] (1) Slab pretreatment, heating a slab of a certain thickness to the rolling temperature and holding the hot slab for a certain period of time, wherein the thickness of the slab is 25mm, the rolling temperature is 1150°C, and the holding time is 150min.

[0040] (2) The parameters of the rolling mill are set. The patterned plate roll in Example 1 is used as the upper roll and the flat roll is used as the lower roll. The thickness of the rolled plate between the two roll surfaces is adjusted, and the thickness of the rolled plate is 1.9 mm.

[0041] (3) Roll the checkered plate, put the processed slab into the rolling mill, and roll the checkered plate at a speed of 8m / s~11m / s.

[0042] The pass rate of the rolled checkered plate is 97.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com