Flexible display panel, manufacturing method, flexible display device

A flexible display and panel technology, applied in the direction of nonlinear optics, climate sustainability, final product manufacturing, etc., can solve the problems of reduced service life and service life of light-emitting devices in the flexible display substrate 1

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

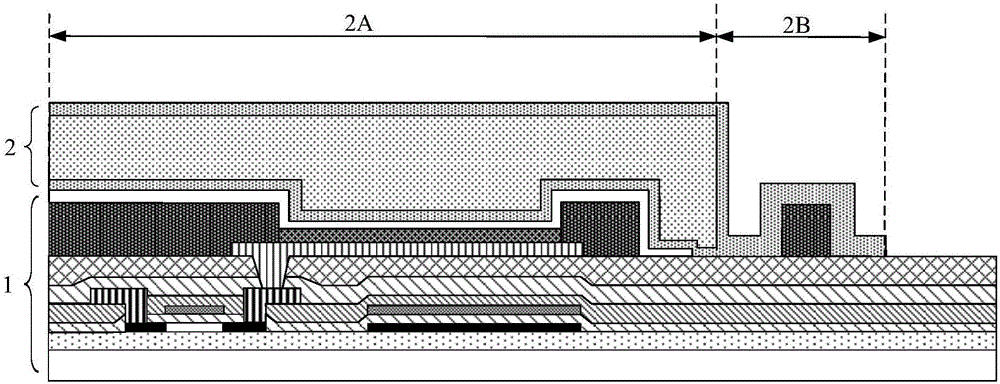

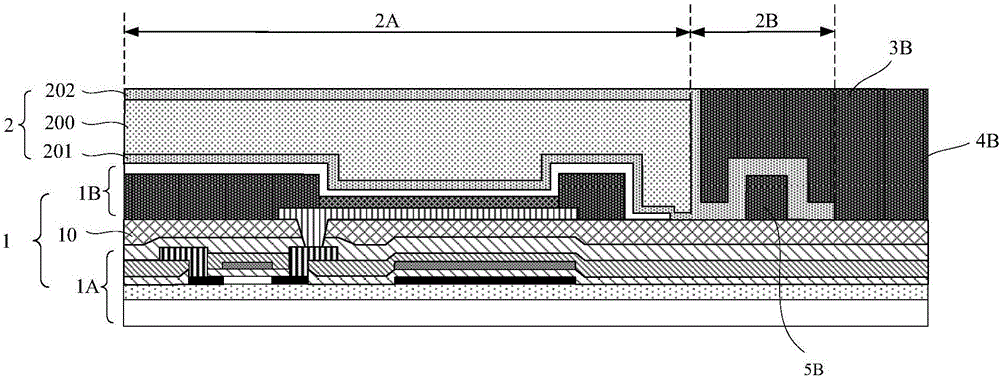

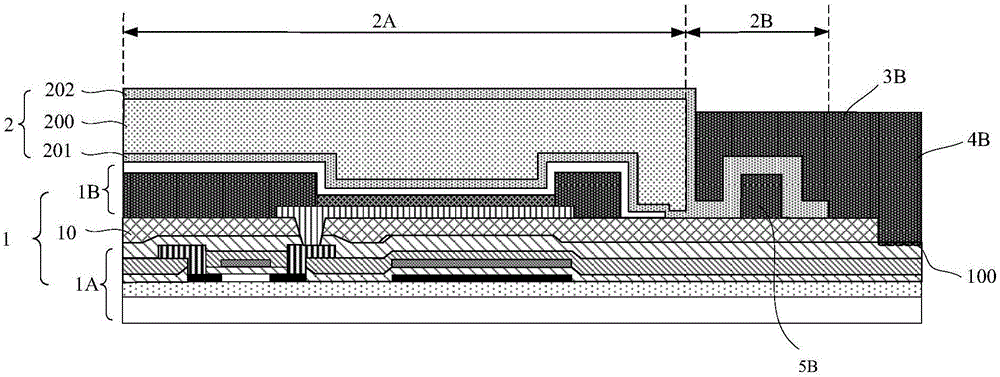

[0032] see figure 2 with image 3 , the embodiment of the present invention provides a flexible display panel, including a flexible display substrate 1, and an encapsulation structure 2 arranged on the surface of the flexible display substrate 1, the part of the encapsulation structure 2 corresponding to the non-display area is an inorganic encapsulation structure 2B; the flexible display panel An organic encapsulation layer 3B covering the inorganic encapsulation structure 2B is also included.

[0033] When the flexible display panel is bent, bending stress is generated, and the bending stress is absorbed by the organic encapsulation layer 3B, so that the bending stress acting on the inorganic encapsulation structure 2B is reduced.

[0034] Through the bending process of the flexible display panel provided by this implementation, it can be seen that since the organic encapsulation layer 3B covers the inorganic encapsulation structure 2B, and the organic encapsulation layer ...

Embodiment 2

[0062] see Figure 2 ~ Figure 4 , the embodiment of the present invention also provides a method for manufacturing a flexible display panel, including:

[0063] Step S1: providing a flexible display substrate 1, the flexible display substrate 1 includes a display area and a non-display area;

[0064] Step S2: forming an encapsulation structure 2 on the surface of the flexible display substrate 1, and the part of the encapsulation structure 2 corresponding to the non-display area is an inorganic encapsulation structure 2B;

[0065] Step S3: forming an organic encapsulation layer 3B covering the inorganic encapsulation structure 2B on the surface of the inorganic encapsulation structure 2B.

[0066] Compared with the prior art, the beneficial effect of the method for manufacturing the flexible display panel provided by the embodiment of the present invention is the same as that of the flexible display panel provided by the first embodiment above, and will not be repeated here. ...

Embodiment 3

[0080] see figure 2 with image 3 , the embodiment of the present invention also provides a flexible display device, including the flexible display panel provided in the first embodiment.

[0081] Compared with the prior art, the flexible display device provided by the embodiment of the present invention has the same beneficial effects as the flexible display panel provided by the first embodiment, and details are not repeated here.

[0082] Wherein, the flexible display device provided in the above embodiments can be any product or component with a display function such as a mobile phone, a tablet computer, a television, a monitor, a notebook computer, a digital photo frame or a navigator.

[0083] In the description of the above embodiments, specific features, structures, materials or characteristics may be combined in any one or more embodiments or examples in an appropriate manner.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com