Prefabricated comprehensive pipe gallery tensioning method

A comprehensive pipe gallery and tensioning technology, applied in water conservancy projects, artificial islands, underwater structures, etc., can solve the problem that there is no way to ensure the compression of the two pipe gallery waterstops, and the sealing effect of the overall prefabricated pipe gallery cannot be ensured, etc. problem, to the effect of reducing the likelihood of cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

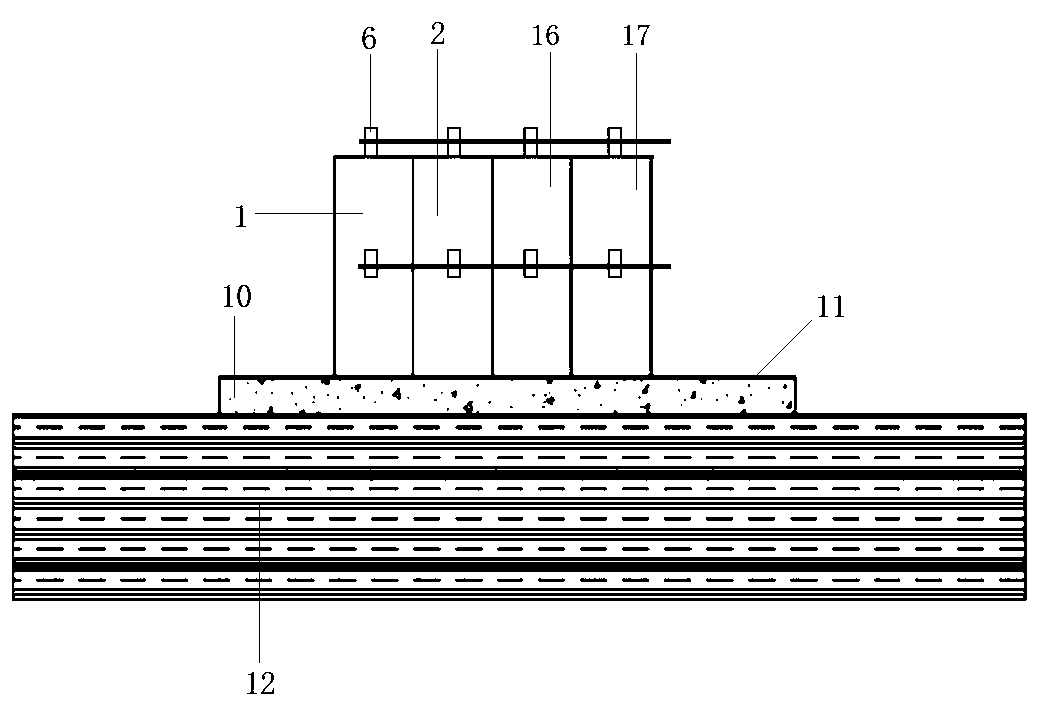

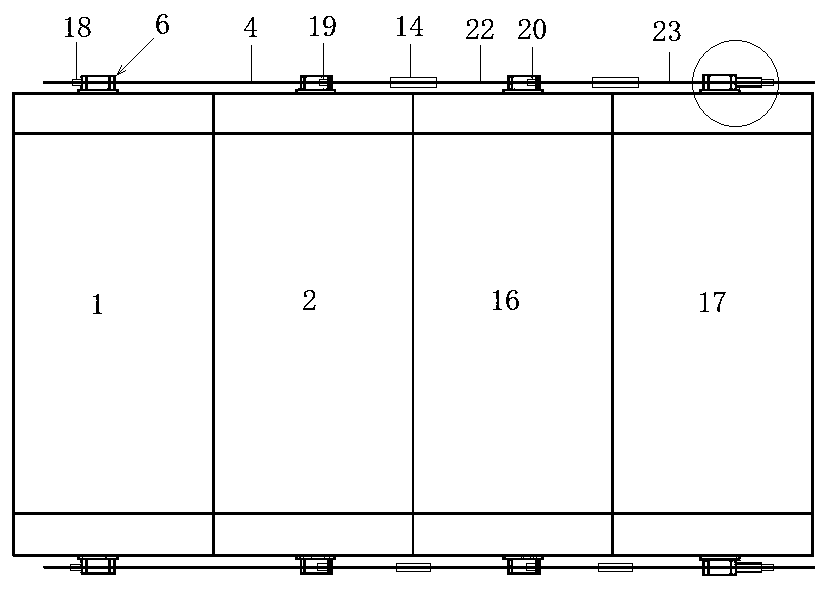

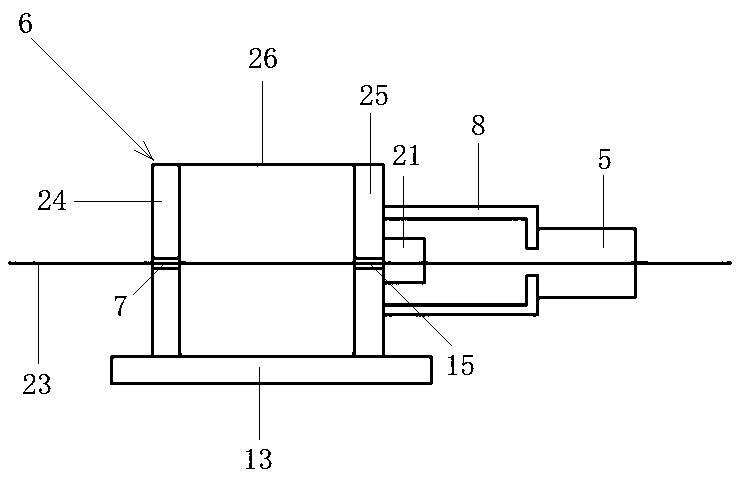

[0022] Embodiment: The prefabricated comprehensive pipe gallery tensioning method in this embodiment is used to compress the waterproof components between adjacent pipe gallery segments, and the anchor points are arranged at different positions of the two-way corbels 6 to avoid tensioning the pipes. When the corridor section is 16, the tension force is transferred to the pipe gallery section 1 and the pipe gallery section 2 that have been stretched and are close to each other; thus avoiding that the pipe gallery section 1 and the pipe gallery section 2 bear more than the design value The compression force is thus crushed, and at the same time, the pipe gallery section 16 is moved closer to the pipe gallery section 2, and the pipe gallery section 17 is closely attached to the pipe gallery section 16 by the same method; The step of pulling and then permanently prestressing and tensioning ensures that the waterstop as a waterproof component is always in a compressed state to ensur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com