Anti-corrosion reinforcing structure for column

A technology for strengthening structures and columns, which is applied in building construction, building maintenance, construction, etc., can solve problems such as shortened service life, reduced bearing capacity of column structures, and reduced structural durability, so as to achieve high practical value, prolong service life, Possible reduced effect of cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

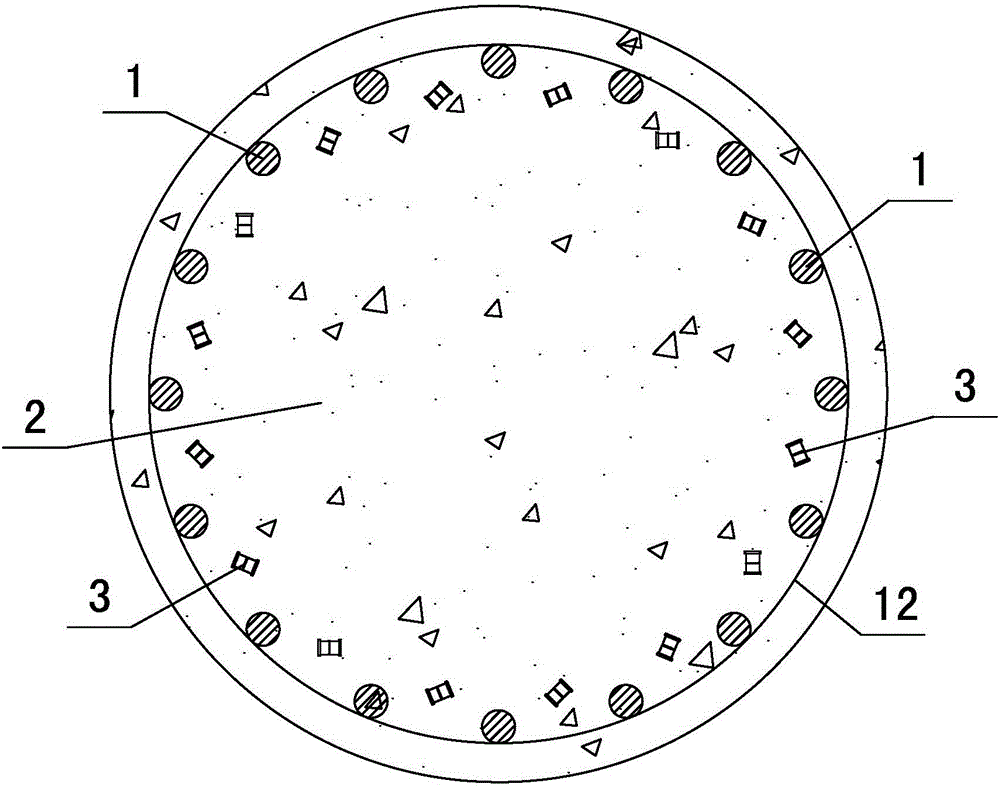

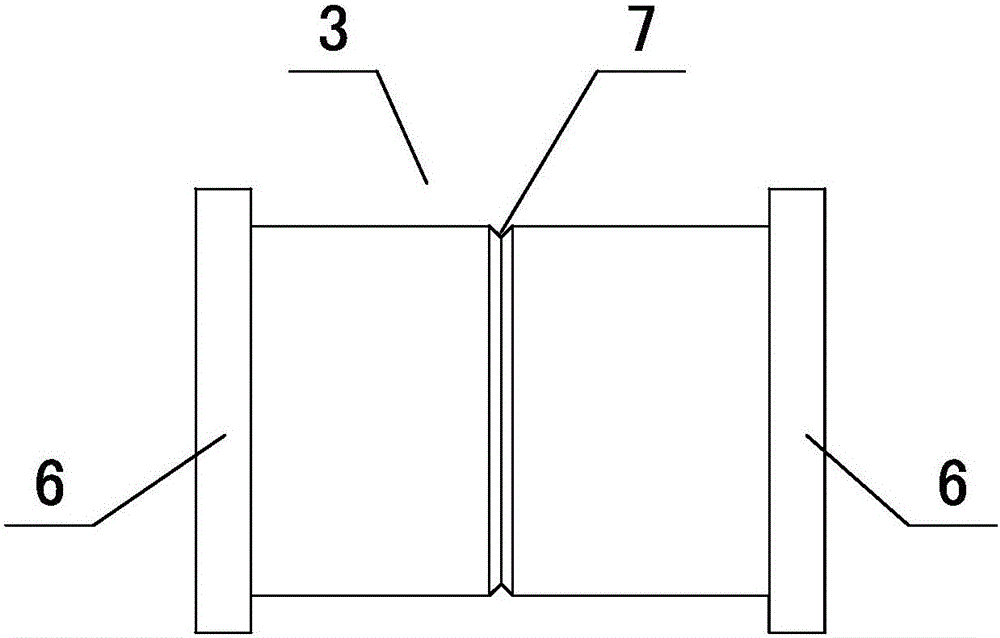

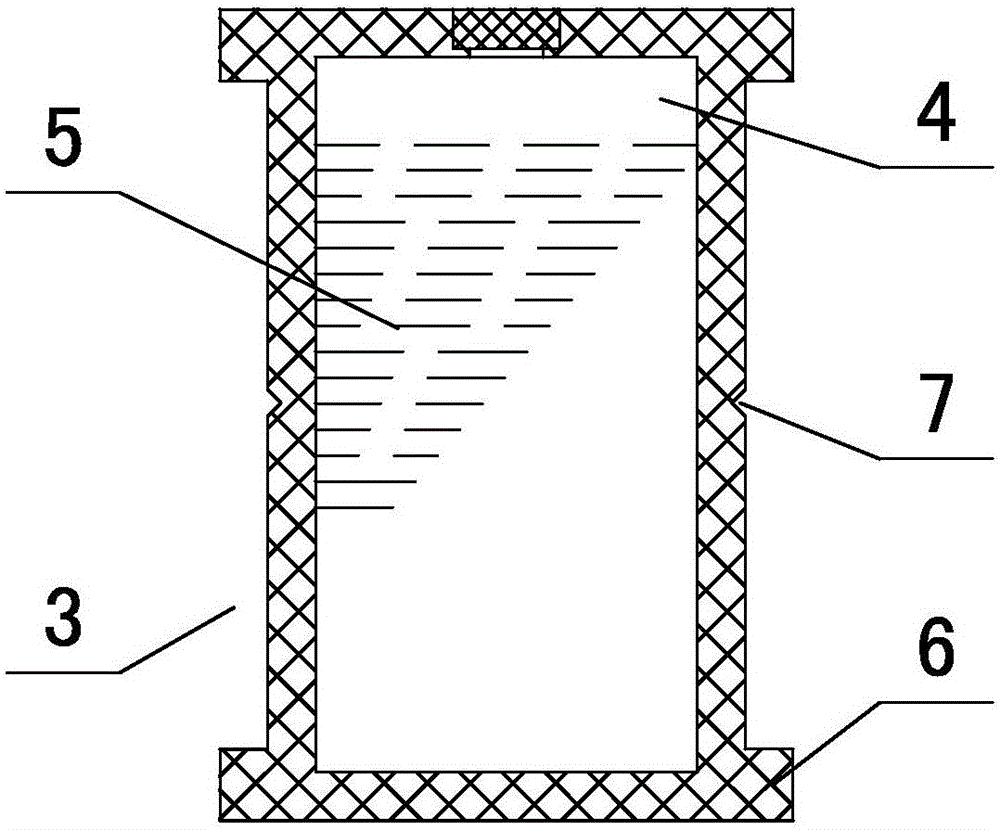

[0024] in figure 1 In the shown embodiment 1, a column anticorrosive reinforcement structure, the column includes concrete and main steel bars 1 arranged in the concrete, and the concrete 2 of the column is provided with a caulking agent release block 3 (see figure 2 image 3 ), the distribution density of the caulk release block near the outer circumference of the cross section of the column is greater than the distribution density of the caulk release block close to the center of the cross section of the column; the caulk release block is a rectangular parallelepiped structure, made of resin material, and the outer peripheral surface of the cuboid is set There is a reticulated structure (not shown in the figure), both ends of the length of the cuboid are provided with stepped structures 6 protruding from the sides of the cuboid, and the inside of the cuboid is provided with a cavity 4; the outer side of the cuboid is provided with easy cracks surrounding the cuboid Slot 7, one...

Embodiment 2

[0026] in Figure 4 In the illustrated embodiment 2, FRP reinforcing ribs 11 are further provided on the outside of the main steel bars of the column, and the FRP reinforcing ribs are fixed on the outside of the stirrups 12 and are arranged in a staggered manner with the main steel bars of the column. The concrete of Example 2 is also mixed with tensile nails 8. The tensile nails are made of high-strength steel, and both ends of the tensile nails are provided with end rings 9 (see Figure 5 ), the ring planes of the end rings at both ends of the tensile studs are perpendicular to each other, and the distribution density of the tensile studs near the outer circumference of the cross section of the column is greater than the distribution density of the tension studs near the center of the cross section of the column. The volume of the caulking agent release block in this embodiment is 5 cubic centimeters, and the filling amount of the crack filler in the caulking agent release bloc...

Embodiment 3

[0028] in Image 6 In the illustrated embodiment 3, the concrete near the column and the outer circumference of the column is infiltrated with non-metallic fibers 10, and the non-metallic fibers are plastic steel fibers, polypropylene fibers or polyacrylonitrile fibers, and the non-metallic tensile fibers The distribution position is located on the outer side of the main steel bar at the outer circumference of the column cross section. The volume of the caulking agent release block of this embodiment is 15 cubic centimeters, the filling volume of the crack filler in the caulking agent release block is 10 ml, the crack filler is an adhesive, and the adhesive has a yellow color. , And the rest is the same as embodiment 1 or embodiment 2.

[0029] The concrete of the column of the present invention is provided with a caulking agent releasing block. The caulking agent releasing block is mixed into the concrete when the column is poured and solidified together with the concrete. When...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com