Preparation process of Al-Si-Mg-B-Mn casting alloy with excellent flowing property

An al-si-mg-b-mn, flow performance technology, applied in the field of aluminum alloy materials, can solve the problem that the fluidity requirements of aluminum alloy thin-wall casting cannot be met, the refinement limit refinement effect is unstable, and the improvement effect is not good. Obvious and other problems, to achieve the effect of reducing loose pores, enhancing feeding ability, and reducing the possibility of cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

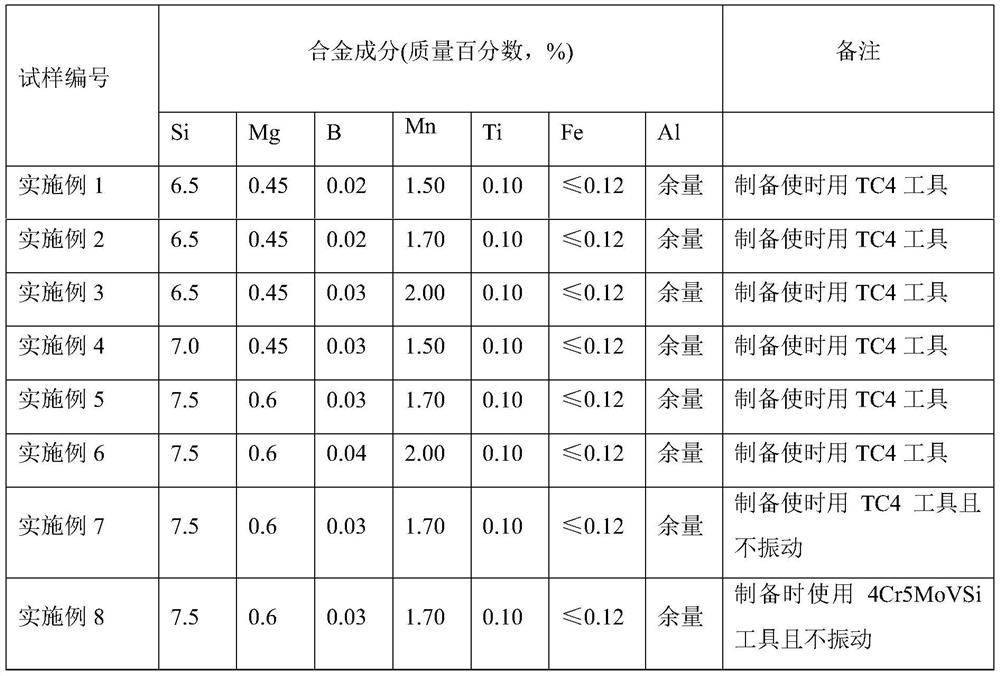

Examples

Embodiment 1

[0039] This embodiment prepares hypoeutectic Al-Si-Mg-B-Mn casting alloy according to the following steps:

[0040] 1. Calculation of ingredients: according to the mass percentage of 91.43% Al, 6.5% Si, 0.45% Mg, 0.02% B, 1.50% Mn and 0.10% Ti, weigh pure aluminum, Al-Si master alloy, Al-Mg master alloy, Al-B master alloy, Al-Mn master alloy and Al-Ti master alloy complete the batching;

[0041] 2. Coating and drying: In order to prevent the aluminum alloy melt from reacting with the tool during the casting process, the coating (mainly composed of ZnO and NaSiO 3 , the composition ratio is 3:1) evenly coated on the graphite clay crucible, melting tools and molds, and put the graphite clay crucible in the melting furnace to dry. Drying and preheating in a drying oven at -300°C;

[0042] 3. Smelting and casting: Add the weighed Al-Si master alloy and pure aluminum into the graphite crucible which has been preheated to 300°C in sequence, and then raise the temperature to 730°C ...

Embodiment 2

[0048] The ingredients of this embodiment are shown in Table 1.

[0049] The preparation method of this embodiment is the same as that of Example 1.

Embodiment 3

[0051] The ingredients of this embodiment are shown in Table 1.

[0052] The preparation method of this embodiment is the same as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com