Marine crank throw die forging forming method and die

A technology for forming molds and bell cranks, which is applied in the direction of manufacturing tools, forging/pressing/hammer devices, forging/pressing/hammering machinery, etc., which can solve the problems of large die forging forming force and increased manufacturing cost, and reduce die forging Forming force, reduction of die forging cost, and improvement of internal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

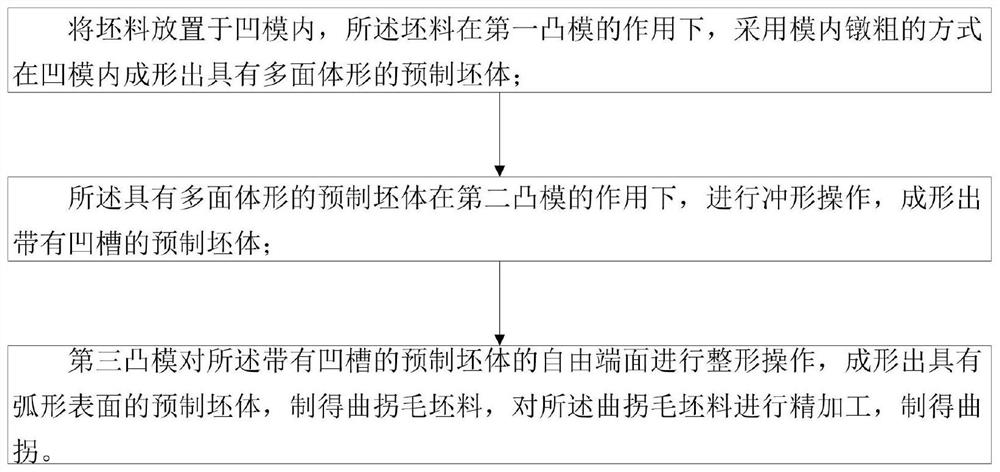

[0077] This embodiment provides a method for forging a marine crank throw, which includes the following steps:

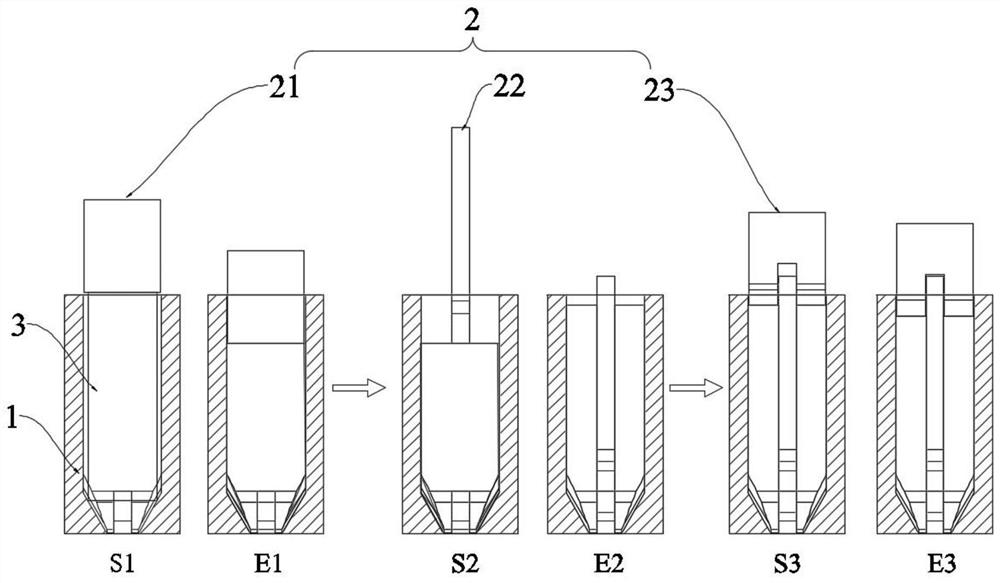

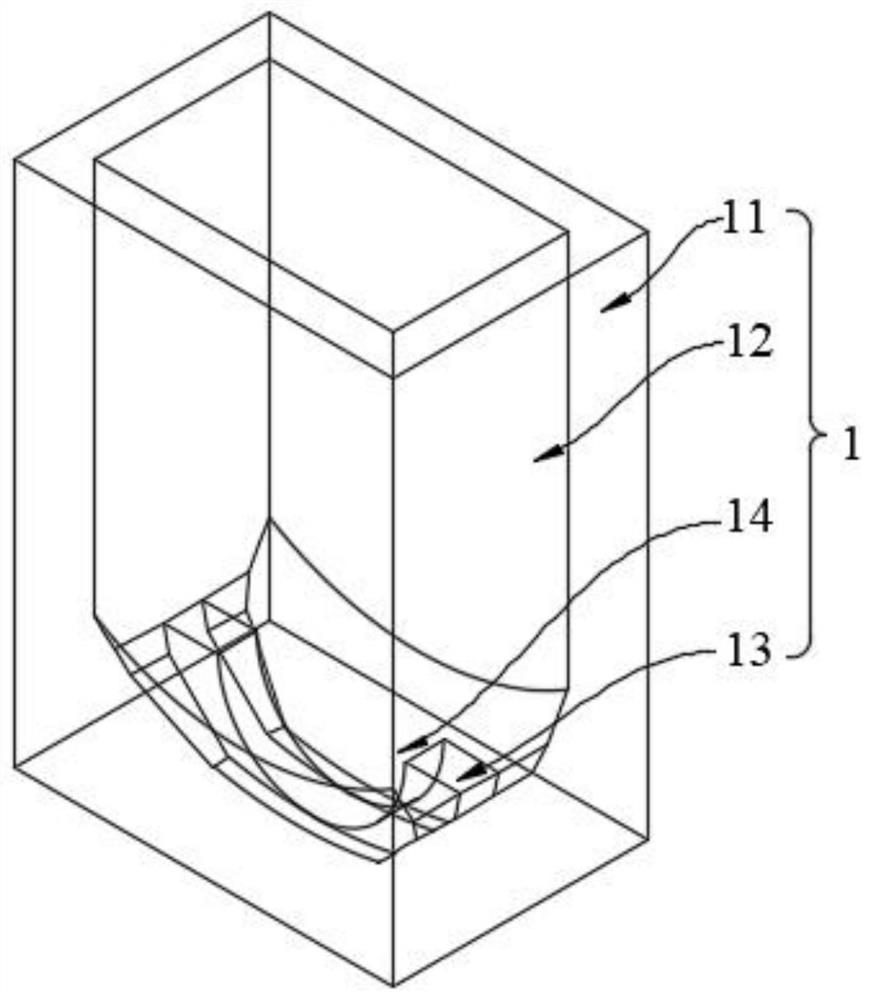

[0078] 1.1 Heat the billet to 1220-1250°C, after heating to facilitate upsetting and forming, take the billet with lifting tongs, place the billet in the die 1 with a cavity, and then connect the first punch 21 with a flat working end to the After the center of the die 1 is aligned, the blank 3 is overall upset in the mold through the first punch 21, the upsetting stroke is 550mm, and a prefabricated body with a polyhedron shape is formed;

[0079] 1.2 After upsetting, move the press table, move the die 1, the polyhedron-shaped prefabricated body and the first punch 21 out of the press together, and at the same time, place the first punch that has been placed on the work table in advance and adjusted its position. The second punch 22 is moved into the press, and is connected with the hammer seat 4 of the press; the second punch 22 is removed from the die 1, and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com