High-strength steel rolling hot-forming technology

A hot forming, high-strength steel technology, applied in the field of ultra-high-strength steel forming, can solve the problems of expensive forming equipment, low product yield, slow production cycle, etc., and achieve the effect of reducing residual stress, increasing dimensional accuracy, and reducing strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

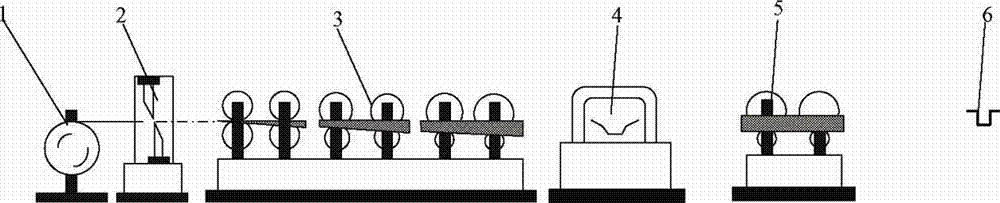

[0032] see figure 1 , the high-strength steel hot roll forming process of the present invention is: the uncoiler 1 uncoils and cuts the steel strip into a sheet material with a required length through the shearing machine 2; the high-strength steel material is moved to the roll forming equipment 3 and formed into a semi-finished product ;Transfer the semi-finished product to the heating equipment 4 and heat it to 800°C, and keep it warm for 5 minutes; transfer the high-temperature semi-finished product to the shaping (rolling) equipment 5 again for size calibration and shaping, and then in the shaping (rolling) equipment 5. After forming Product 6 is subjected to pressure quenching under load and cooled to room temperature to obtain the required microstructure and mechanical properties.

Embodiment 2

[0034] 1) The uncoiler 1 uncoils and cuts the steel strip into a sheet with the required length through the shearing machine 2; 2) Moves the high-strength steel sheet to the roll forming equipment 3 to form a semi-finished product; 3) Transfers the semi-finished product to the heating Heating to 1100°C in equipment 4 and keeping it warm for 3 minutes; 4) Transfer the high-temperature semi-finished product to shaping (rolling) equipment 5 again for size calibration and shaping; 5) Then shape the formed product in shaping (rolling) equipment 5 6 Carry out pressure quenching under load conditions and cool to room temperature to obtain the required microstructure and mechanical properties.

Embodiment 3

[0036] 1) The uncoiler 1 uncoils and cuts the steel strip into a sheet with the required length through the shearing machine 2; 2) Moves the high-strength steel sheet to the roll forming equipment 3 to form a semi-finished product; 3) Transfers the semi-finished product to the heating Heating to 1000°C in equipment 4 and keeping it warm for 4 minutes; 4) Transfer the high-temperature semi-finished product to the shaping (rolling) equipment 5 again for size calibration and shaping; 5) Then shape the formed product in the shaping (rolling) equipment 5 6 Carry out pressure quenching under load conditions and cool to room temperature to obtain the required microstructure and mechanical properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com