Forging and stamping die of brake cylinder seat

A technology of brake cylinders and molds, which is applied in the manufacture of tools, forging/pressing/hammer devices, forging/pressing/hammering machines, etc., to achieve the effects of low forging cost, stable forging quality and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

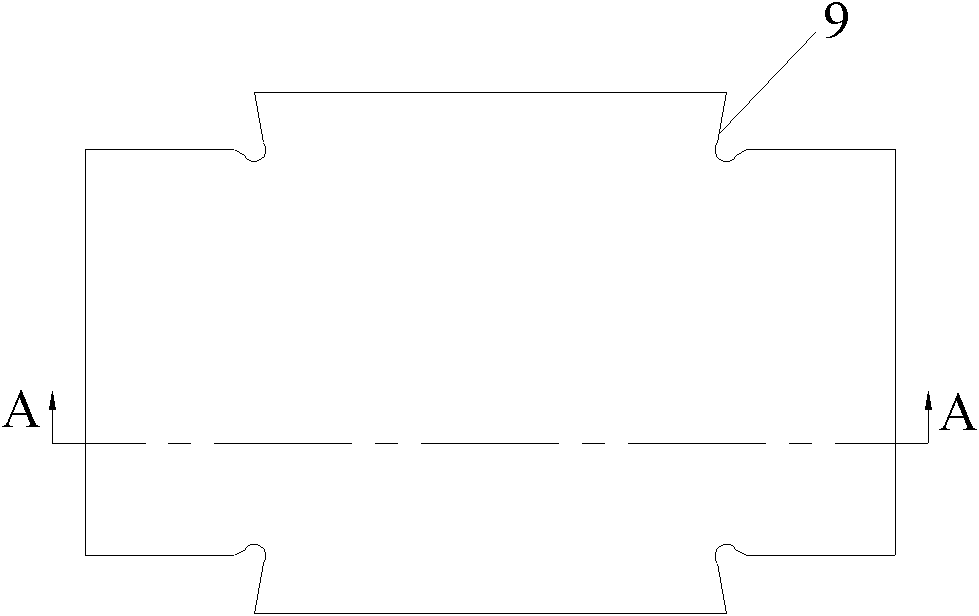

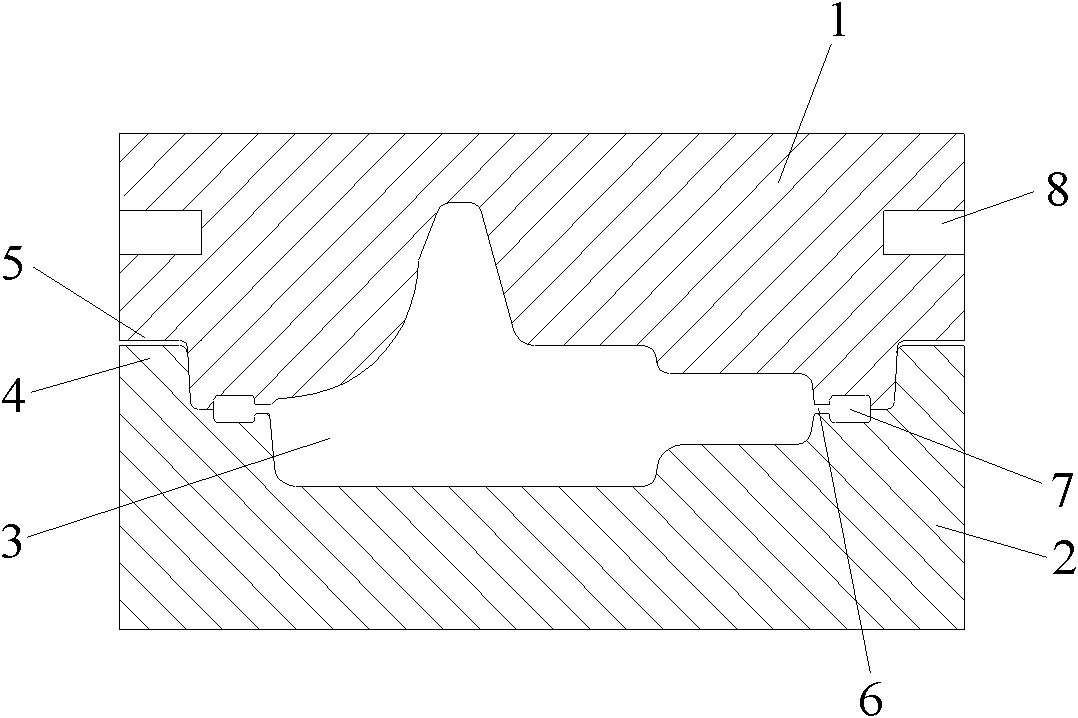

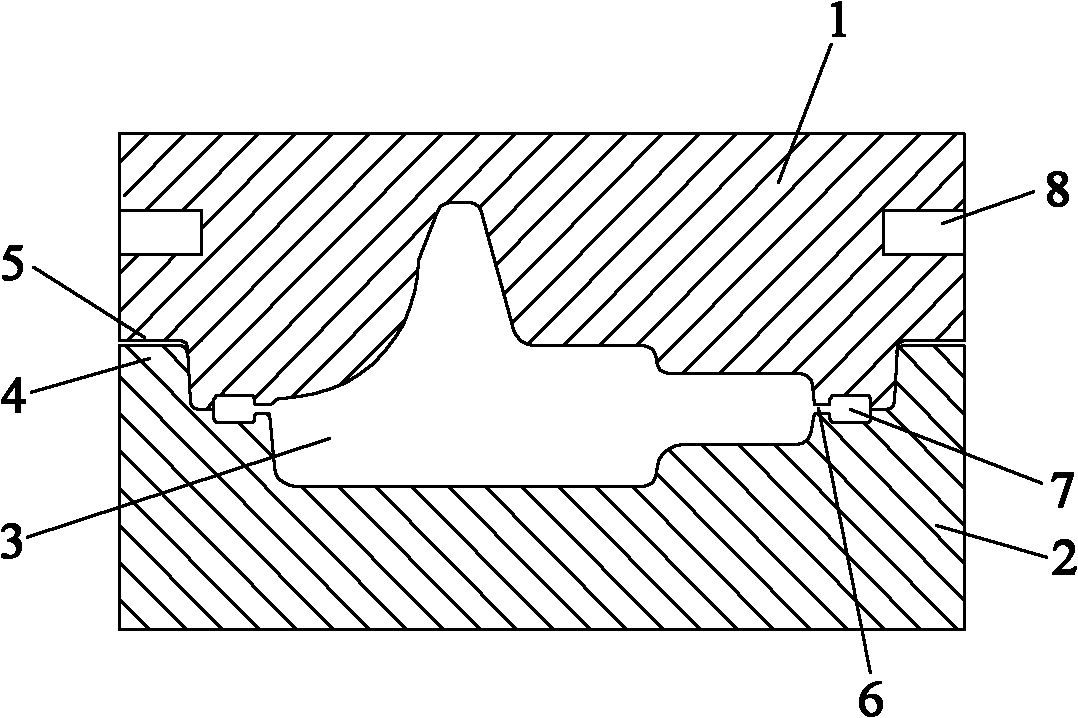

[0014] Example 1, such as Figure 1 to Figure 2 Shown, a kind of forging die of brake cylinder block, it comprises die cavity 3 that forms between upper die 1 and lower die 2 and upper die 1, lower die 2; Described upper die and lower die pass through upper die The concave lock 5 and the convex lock 4 of the lower mold are adapted for positioning, and the concave lock 5 is a concave gap provided around the lower end of the upper mold, and the convex lock 4 is a protrusion provided around the upper end of the lower mold; in order to ensure that the upper mold It can fully contact with the mold surface of the lower mold so as not to make a wrong mold, and there is a gap of 3mm between the concave lock of the upper mold and the convex lock of the lower mold. A flash groove 7 is also arranged on the edge of the mold cavity between the upper mold and the lower mold; a flash bridge portion 6 is arranged between the mold cavity 3 and the flash groove 7, and the flash bridge portion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com