Method for controlling forging deformation of complex plate-like die forging

A control method and technology of deformation amount, applied in the field of forging technology, can solve the problem of large design amount of remaining forging pieces, and achieve the effects of reducing raw materials, reducing design amount, and increasing deformation amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

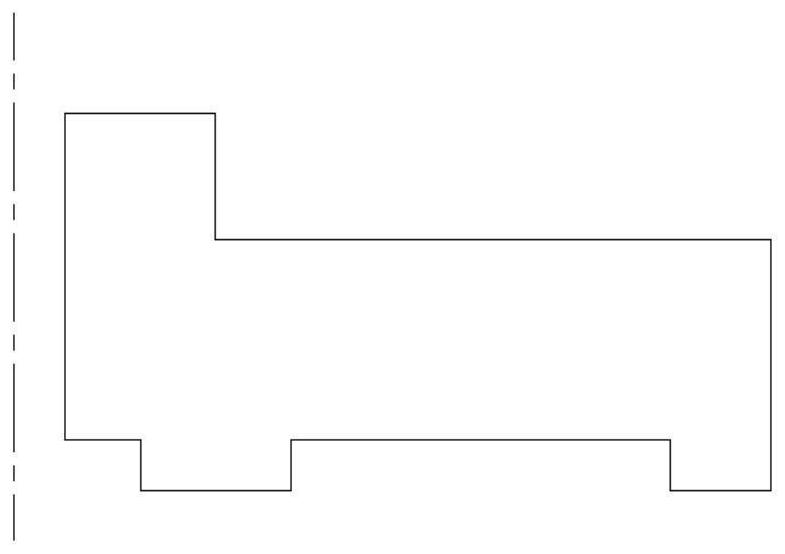

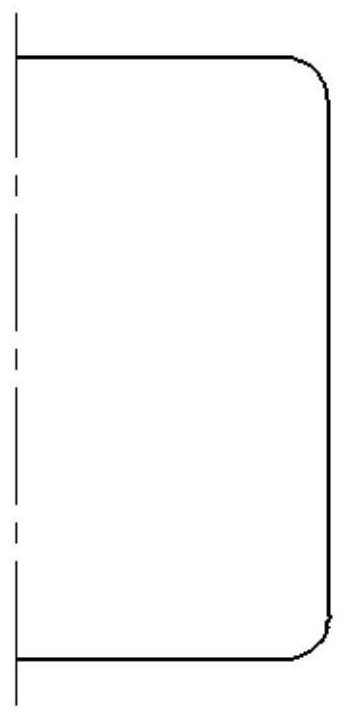

[0061] Forged by die forging Figure 1a The parts shown in are described as examples, as follows:

[0062] Figure 1a The part shown in is a disc-shaped part with the dotted line as the center of rotation.

[0063] Such as Figure 1a , design the final forging model according to the part drawing according to the principle of small margin design (make the forging model as close as possible to the part and make the forging size as small as possible), such as Figure 1c ; According to the principle of easy forming and no need for machining, the prefabricated model is obtained, such as Figure 1b .

[0064] Based on the designed forging model and preform model, numerical simulation is carried out in deform software to simulate the deformation process from the preform model to the final forging model, analyze the deformation of each area of the forging during forming, and determine the forging process of the part. The area with insufficient deformation during forming is loca...

Embodiment 2

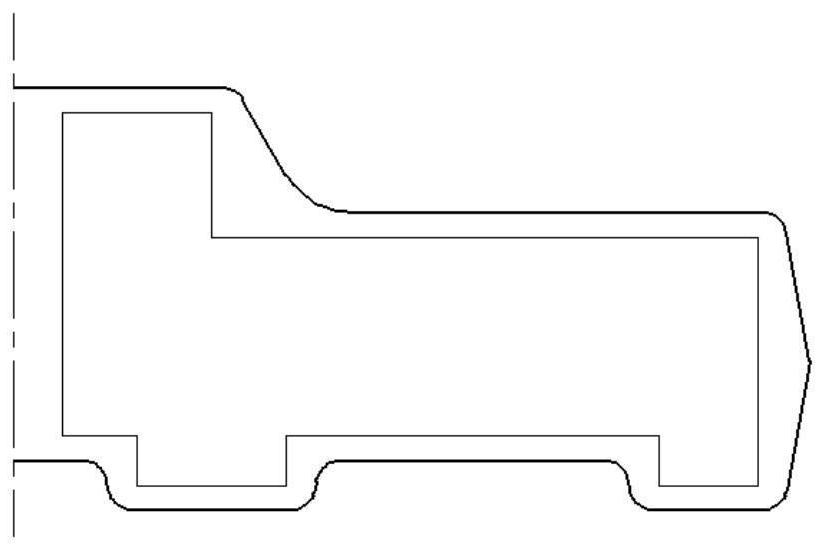

[0076] Forged by die forging Figure 4a The parts shown in are described as examples, as follows:

[0077] Figure 4a The part shown in is a disc-shaped part with the dotted line as the center of rotation.

[0078] Such as Figure 4a , design the final forging model according to the part drawing according to the small margin design principle, such as Figure 4c ; According to the principle of easy forming and no need for machining, the prefabricated model is obtained, such as Figure 4b .

[0079] Based on the designed forging model and preform model, numerical simulation is carried out in deform software to simulate the deformation process from the preform model to the final forging model, analyze the deformation of each area of the forging during forming, and determine the forging process of the part. The area with insufficient deformation during forming is located in the upper left corner area and the lower left corner area of the forging, such as Figure 4d , the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com