A chain plate chip conveyor structure

A chain plate chip conveyor and design structure technology, applied in the direction of manufacturing tools, metal processing machinery parts, metal processing equipment, etc., can solve the problems of poor interchangeability, complex structure, low production efficiency, etc., and achieve design quality improvement and reduction The effect of reducing the amount of welding and reducing the cost of equipment use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

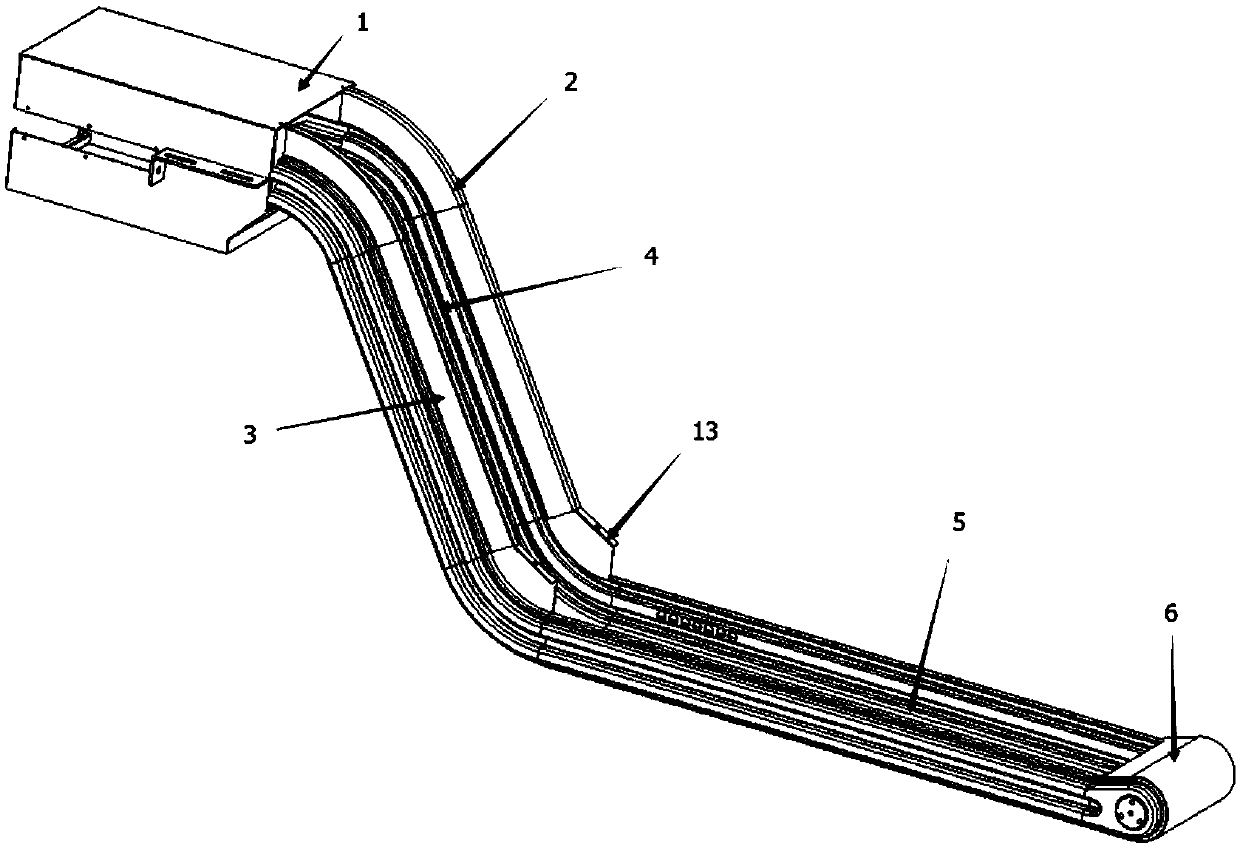

[0031] Example 1, as Figure 1-4 shown:

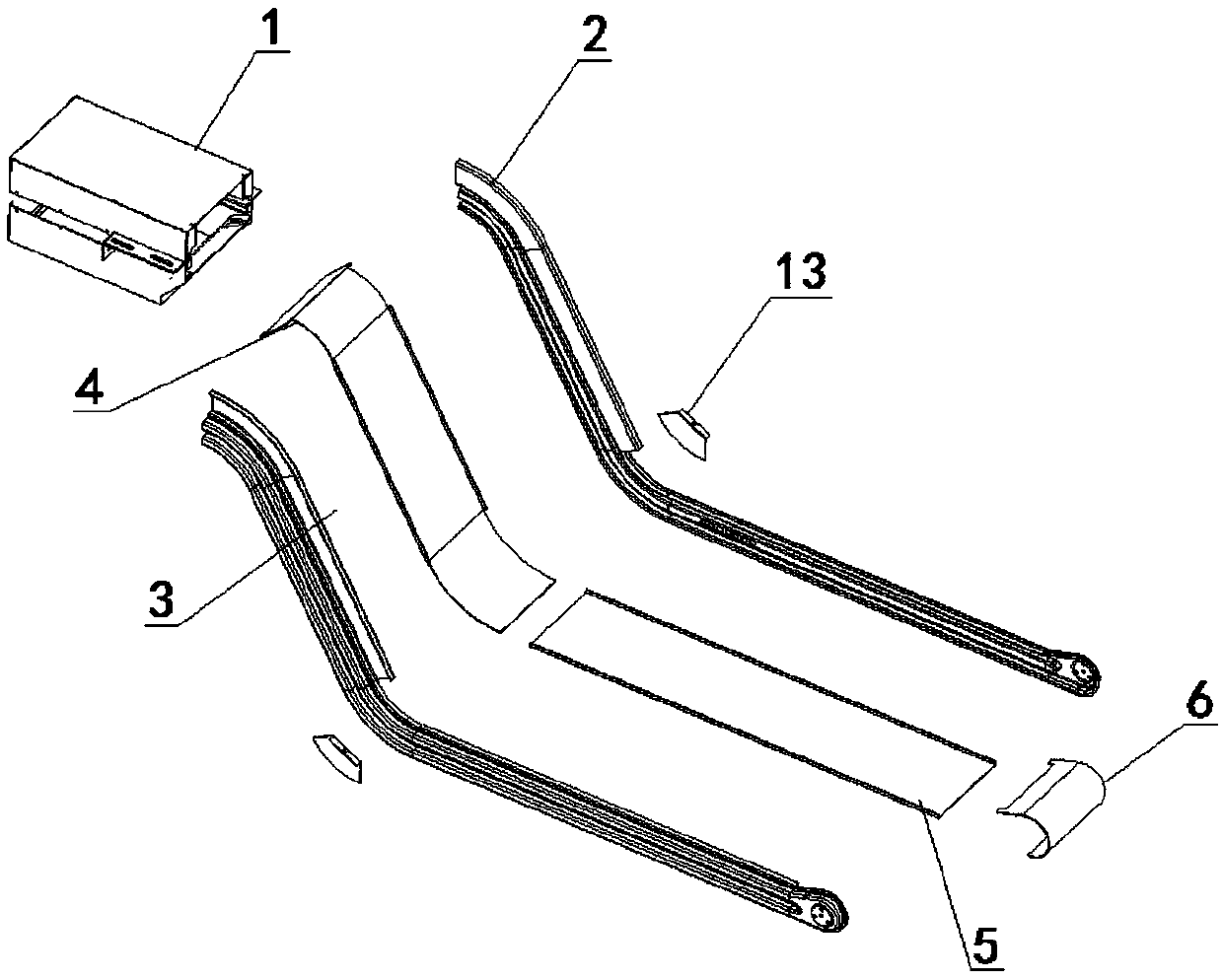

[0032] A chain plate chip conveyor structure includes a machine head module 1, a right side 2, a left side 3, a bottom sheet metal 4 of a lifting section, a bottom sheet metal 5 of a horizontal section, a tail arc sheet metal 6 and a side plate 13; The upper end of the bottom sheet metal 4 of the lifting section is welded to the head module 1, the lower end of the bottom sheet metal 4 of the lifting section is welded to the bottom sheet metal 5 of the horizontal section, and the lower end of the bottom sheet metal 5 of the horizontal section is welded to the tail arc sheet metal 6; The materials used for 3 and the right side 2 are "bow" type sheet metal materials. The left side 3 and the right side 2 are symmetrical in structure, and the left side 3 and the right side 2 are symmetrically welded to the bottom sheet metal 4 and the right side of the lifting section. Both sides of sheet metal 5 at the bottom of the horizontal segment;

...

Embodiment 2

[0042] Example 2, as Figure 4-5 shown:

[0043] Figure 4It is a cross-sectional view of the main body of the chip conveyor formed by one-time stamping. It can be seen that it consists of two horizontal section side plates 7 and one horizontal section bottom sheet metal 5. The number of parts is 3 and the number of welds is 2. Figure 5 It is a sectional view of the main body of the existing sheet metal bending process. The main body is composed of a shell 8, a right upper guide rail 9, a right lower guide rail 10, a left upper guide rail 11, and a left lower guide rail 12. The number of parts is 5 , the number of welds to be welded is 6. Therefore, the existing process needs to use a large number of parts and welds, which is not conducive to the rapid and efficient production and preparation of the chip conveyor and the guarantee of dimensional accuracy, and the accumulated deformation of the welding is relatively large.

Embodiment 3

[0044] Example 3, as Figure 1-4 shown:

[0045] A new structure and manufacturing process of chain plate chip conveyor, through standardized and modular design, the main body consists of machine head module 1, right side 2, left side 3, lifting section bottom sheet metal 4, horizontal section bottom sheet metal 5. The tail arc sheet metal 6 and the side plate 13 are composed.

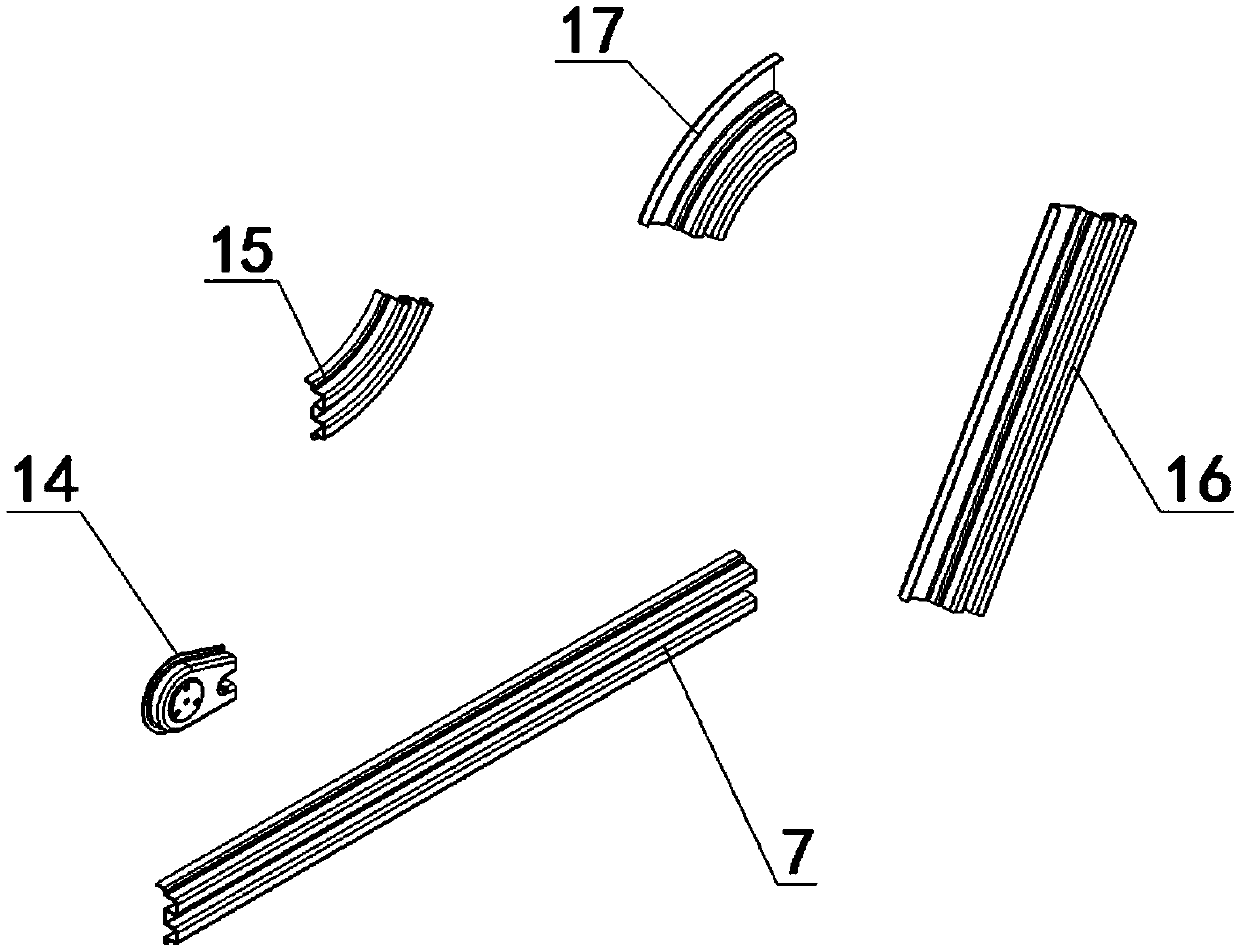

[0046] The manufacturing process mainly involves the one-step stamping and forming process of the following sheet metal parts: the right side 2 includes: the horizontal section side plate 7, the right tail side plate 14, the middle side plate 15, the lifting section side plate 16, and the head side plate 17. Among them, the parts included in the right side 2 are all a stamping forming process; the left side 3 and the side 2 are symmetrically designed, both of which are a one-time stamping and forming process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com