Patents

Literature

46results about How to "Reduce Design Errors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

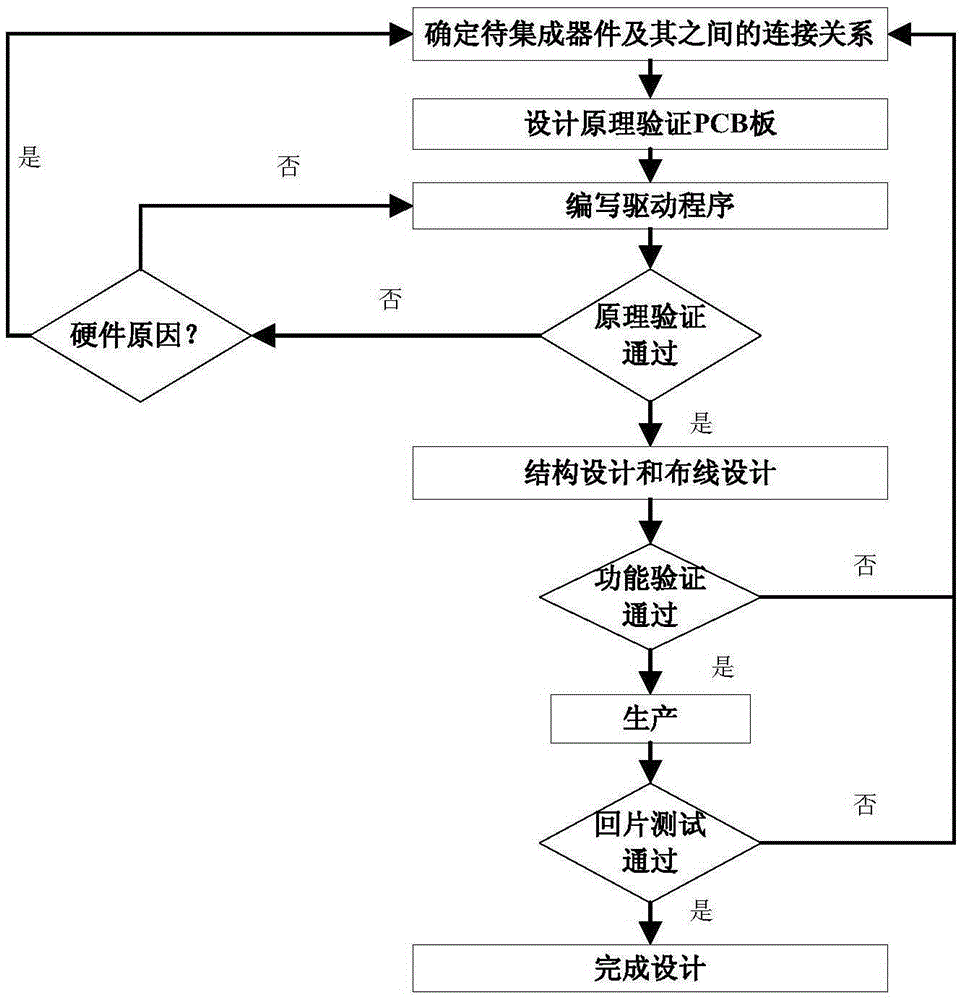

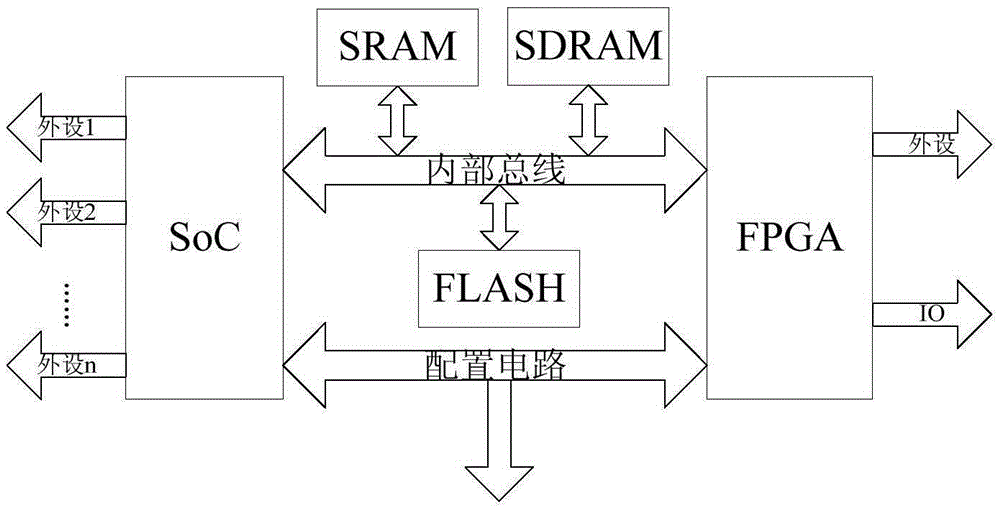

SIP (System In Package) module design method based on board level verification and test system

ActiveCN105279321AAvoid the problem of process confusionImprove integritySpecial data processing applicationsComputer architectureFunctional testing

This invention discloses a SIP module design method based on board level verification and test system. The method comprises the following steps: firstly, selecting a to-be-integrated device and design a principle to verify PCB (Printed Circuit Board); writing a driver to complete the principle verification; secondly, performing structure design and wiring design; at last, performing function verification, and completing chip-returning test and function test. Based on the PCB, this method realizes the principle verification, the function verification and the function test, improves integrity of the design of the SIP module, and avoids the problem of incomplete design work; moreover, since the PCB is reused in the design process, the design workload and difficulty are reduced; the efficiency is improved; and the requirements of the SIP module design are satisfied to the most extent.

Owner:BEIJING MXTRONICS CORP +1

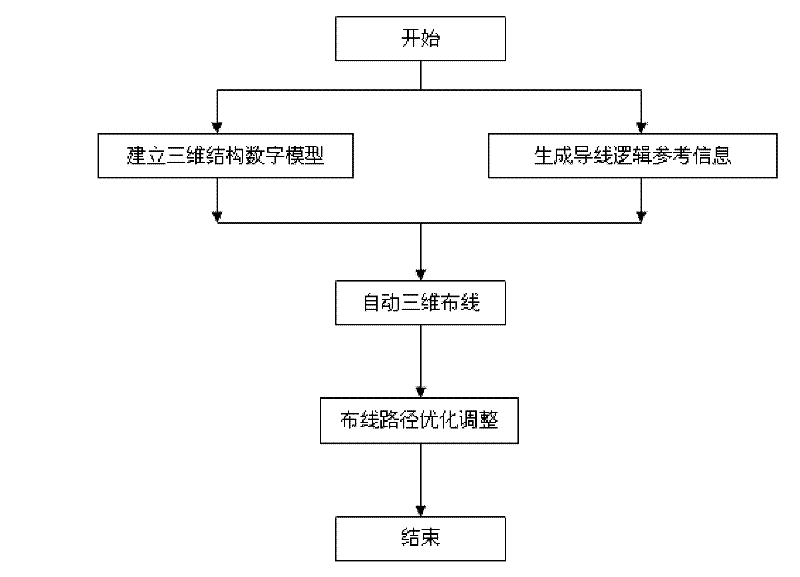

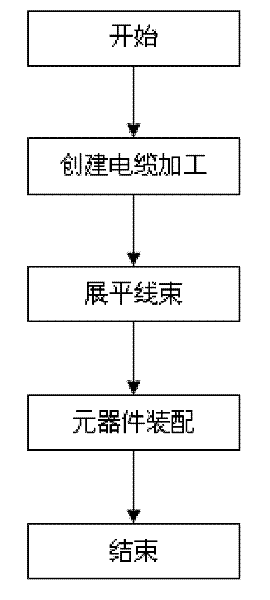

Electrical assembling method for modulator power supply cabinet

InactiveCN102542104AHigh speedQuality improvementSpecial data processing applicationsComputer Aided DesignEngineering

The invention discloses an electrical assembling method for a modulator power supply cabinet, which is characterized by comprising the following steps of: firstly, constructing a three-dimensional wiring operating platform by a computer, importing a three-dimensional structure model of which components are defined on the platform and carrying out three-dimensional wiring according to a cabinet structure model; and then flattening a wire harness and assembling the components, generating a wire harness flattening file, creating a wire harness flattening graph, converting the wire harness flattening graph into a two-dimensional CAD (Computer Aided Design) wire bundle graph, processing cables according to the graph and installing the cables on site. Due to the adoption of the assembling method, the rapid developing speed can be improved, the design error is reduced; the speed and the quality of actually manufacturing a wire bundle are improved; the production period is effectively reduced; and the production working efficiency is improved.

Owner:GLORYMV ELECTRONICS

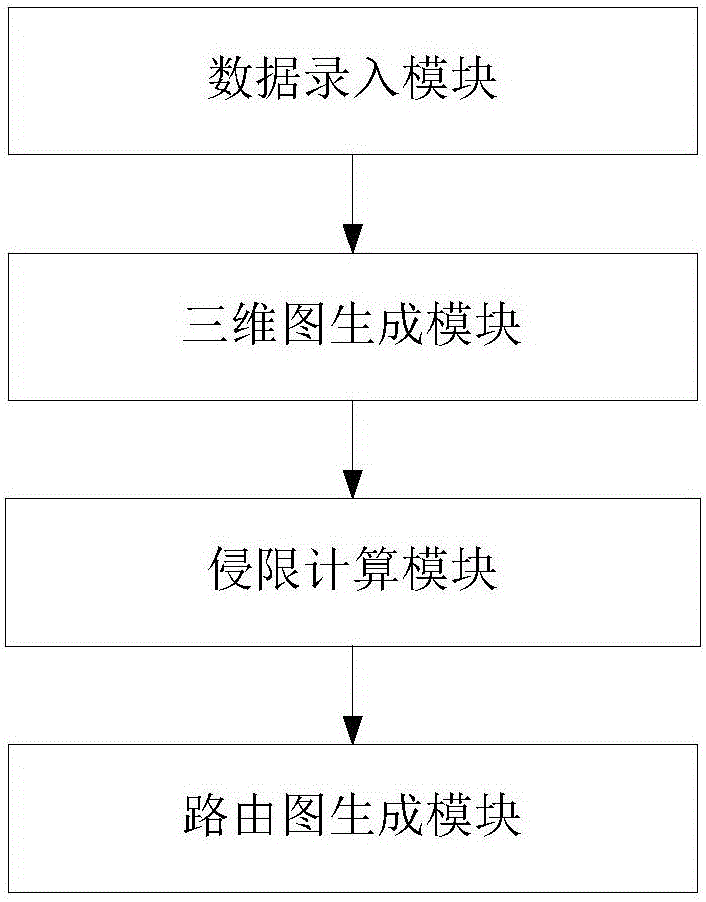

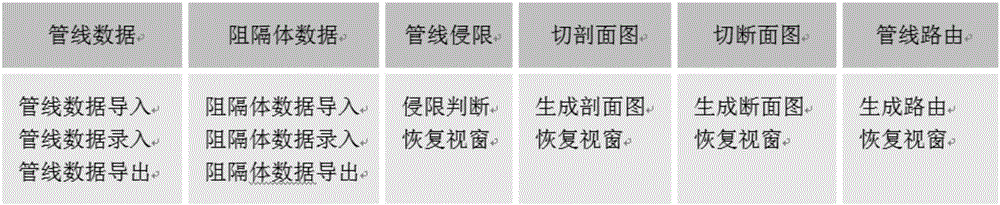

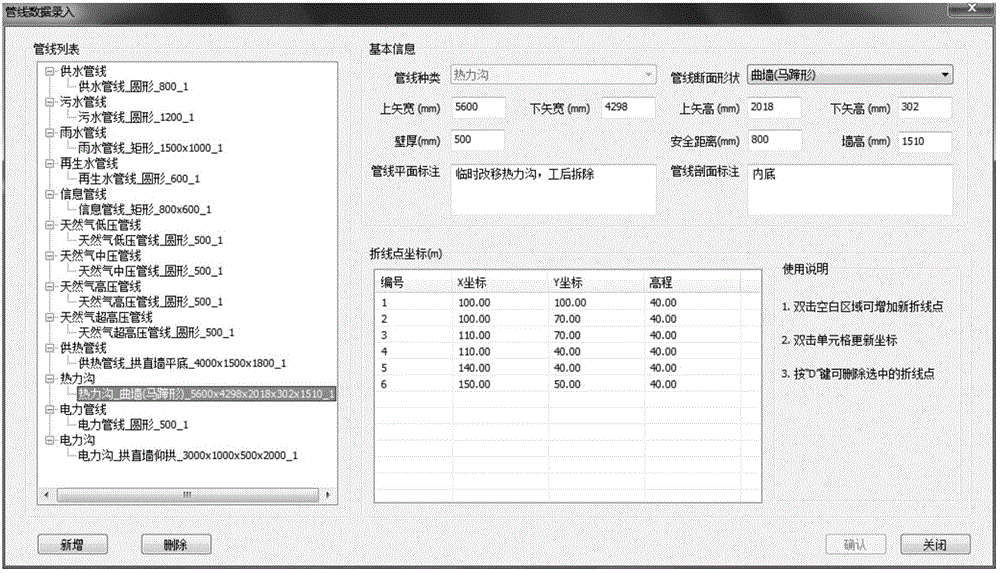

Pipeline routing map generating system and method for newly-built subway station

InactiveCN105760626AIntuitive three-dimensional space positionReduce the burden onGeometric CADSpecial data processing applicationsGraphicsComputer Aided Design

The invention discloses a pipeline routing map generating system and a pipeline routing map generating method for a newly-built subway station. The system is established on a CAD (Computer Aided Design) system platform, and comprises a data input module, a three-dimensional map generating module, an intrusion limit calculating module and a routing map generating module, wherein the data input module is used for inputting pipeline data of the newly-built subway station and obstructing volume data and pipeline data of existing pipelines; the three-dimensional map generating module is used for generating an initial three-dimensional map according to the input data; the intrusion limit calculating module is used for calculating intrusion limit according to the initial three-dimensional map, and respectively marking an intrusion limit part on each of pipelines of the newly-built subway station and the existing pipelines to obtain a three-dimensional map with intrusion limit marks; the routing map generating module is used for generating a pipeline routing map by adopting the principle that the total length of the pipelines is the minimal on the basis that the clearances of the pipelines and obstructing bodies of the newly-built subway station do not intrude on the clearances of the existing pipelines based on the three-dimensional map with the intrusion marks according to a starting point and a terminal point of a pipeline route input by a user. According to the system and the method, the burden of a designer is lightened, the design work efficiency is improved, and design errors are reduced.

Owner:BEIJING JIAOTONG UNIV

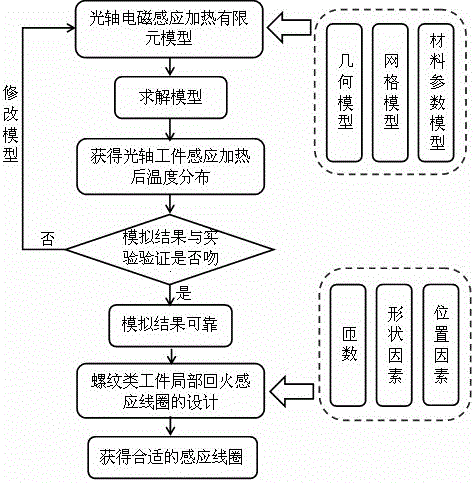

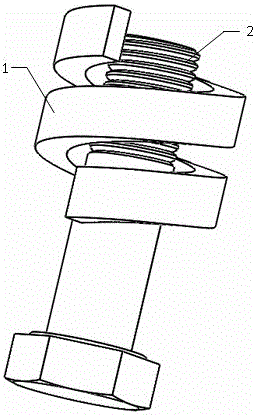

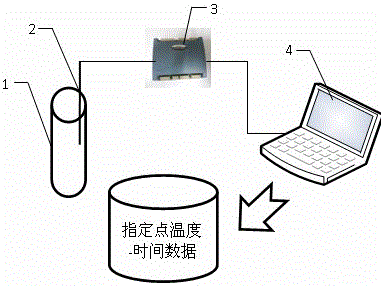

Method for designing local tempering induction coil of ultrahigh-strength steel threaded type workpiece based on finite element simulation

InactiveCN106529005AHomogenization tempering temperatureHigh precisionDesign optimisation/simulationSpecial data processing applicationsOptical axisDesign methods

The invention provides a method for designing a local tempering induction coil of an ultrahigh-strength steel threaded type workpiece based on finite element simulation. A geometrical model is established according to shapes of an ultrahigh-strength steel optical axis workpiece and an induction coil; finite element simulation for induction heating is carried out after grid partition and material attribute loading; a result obtained by simulation is compared with an experimental measurement result; and, if the two are matched well, design of the induction coil of the ultrahigh-strength steel threaded type workpiece in the next step is carried out. The shape factor, the position factor and the number of turns of the induction coil are optimal in design; the designed induction coil can realize that a threaded part of the ultrahigh-strength steel threaded type workpiece has homogenized tempering temperature in an induction heating local tempearing process; finite elements are introduced into the design of the local tempering induction coil of the ultrahigh-strength steel threaded type workpiece; therefore, visualization of temperature distribution in the local tempering induction heating process of the threaded part can be realized easily; a design process is optimized; furthermore, the design mistakes can be reduced; and the design cost is reduced.

Owner:NANCHANG HANGKONG UNIVERSITY

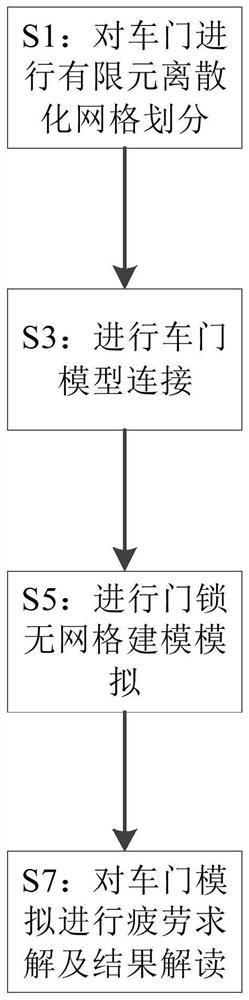

Vehicle door fatigue simulation analysis method

PendingCN112100883AAccurately Predict Closed Door LifeAccurately Predict LifespanGeometric CADDesign optimisation/simulationIn vehicleTransport engineering

The invention discloses a vehicle door fatigue simulation analysis method, and the method at least comprises the following steps: S1, carrying out the finite element discretization mesh generation ofa vehicle door; S3, conducting vehicle door model connection; S5, carrying out door lock mesh-free modeling simulation; and S7, conducting fatigue solving and result interpretation on vehicle door simulation. Therefore, the problem of sharp oscillation of energy at the moment of closing the door due to the fact that a vehicle door lock adopts a physical unit defect can be avoided, and meanwhile, the transmission of vehicle door closing energy can be simulated more truly, so that the stress of the vehicle door is closer to the real door closing process to accurately predict the dangerous position and the door closing service life in vehicle door fatigue; and effective improvement suggestions are provided for design, so that design errors are reduced, the research and development period is shortened, and later rectification waste is avoided.

Owner:宝能(广州)汽车研究院有限公司

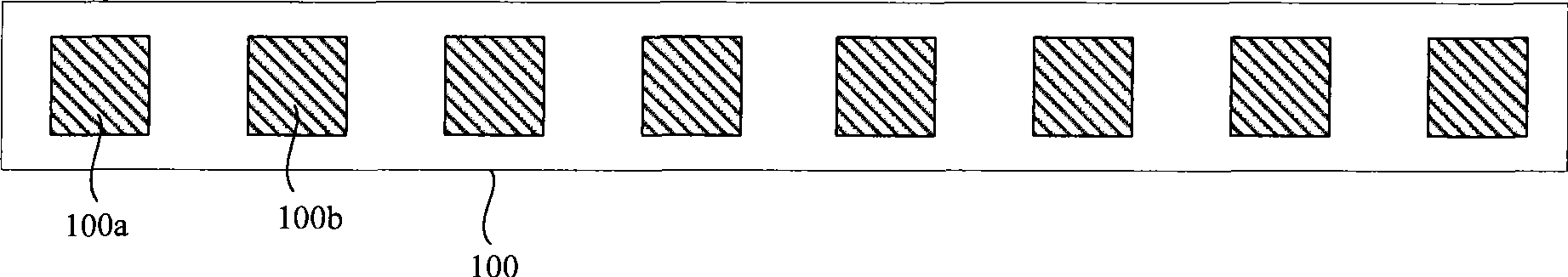

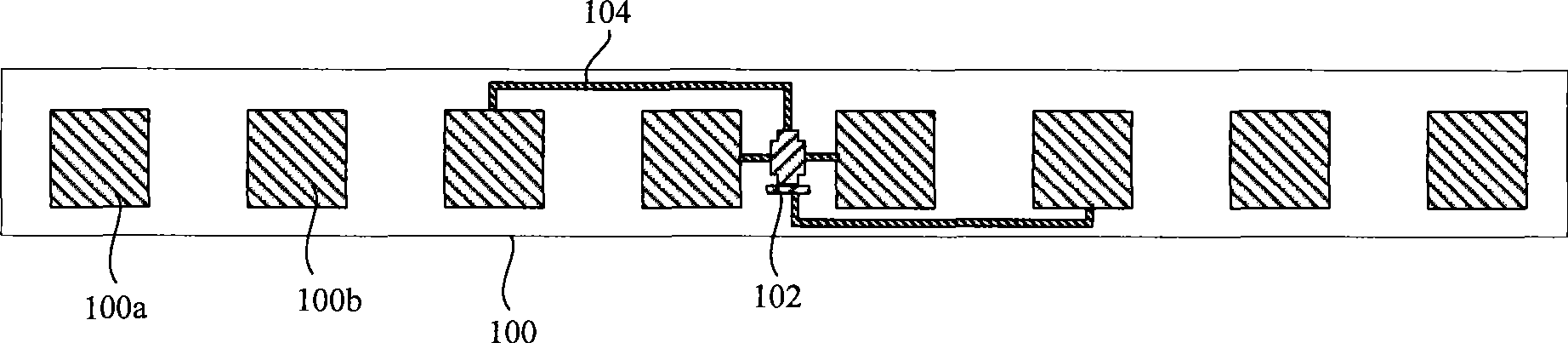

Test structure artwork forming method and system and test structure forming method

ActiveCN101458723ASimplified Design Rule CheckerReduce disconnectionSemiconductor/solid-state device manufacturingSpecial data processing applicationsTime efficientStandard cell

A formation method for test structural layout comprises: forming at least two virtual lead wire welding pad patterns; forming a virtual frame pattern containing the virtual lead wire welding pad patterns; forming single test structure patterns among the virtual lead wire welding pad patterns of the virtual frame parameter, connecting the single test structure pattern with the virtual lead wire welding pad patterns to form a standard unit pattern containing the virtual frame, the virtual lead wire welding pad patterns and the single test structure patterns; forming lead wire welding pad patterns; forming a frame pattern containing the lead wire welding pad patterns; inserting the standard unit pattern into the frame pattern, and aligning the virtual lead wire welding pad patterns of the standard unit pattern to the lead wire welding pad patterns of the frame pattern, to form a test structural layout. The invention provides a system forming test structural layouts, a formation method of test structures and a formation method of layouts. The invention can improve the efficiency of layout formation, save time and reduce error rate.

Owner:SEMICON MFG INT (SHANGHAI) CORP

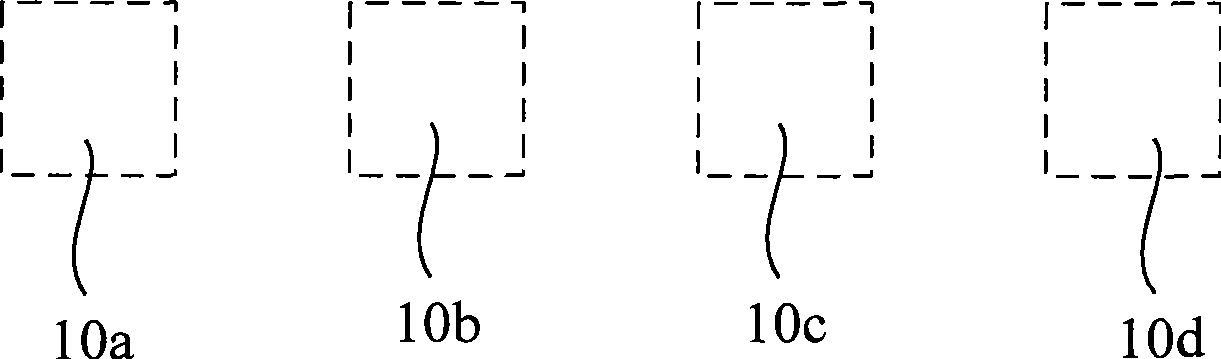

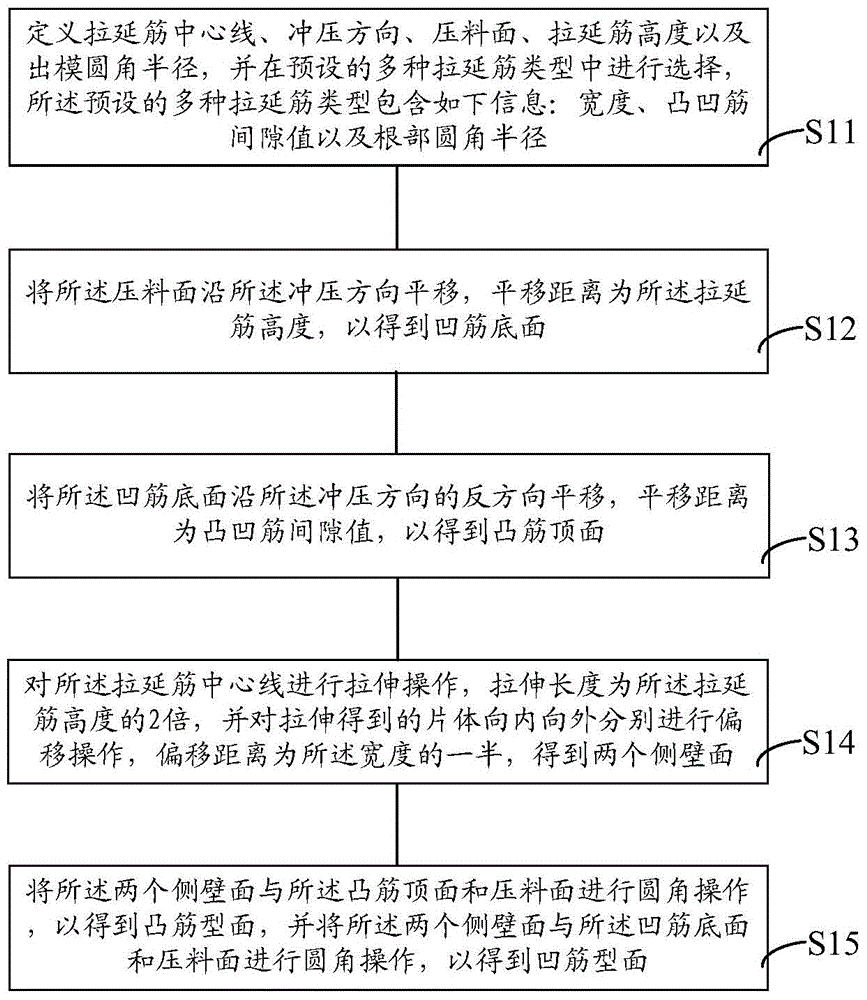

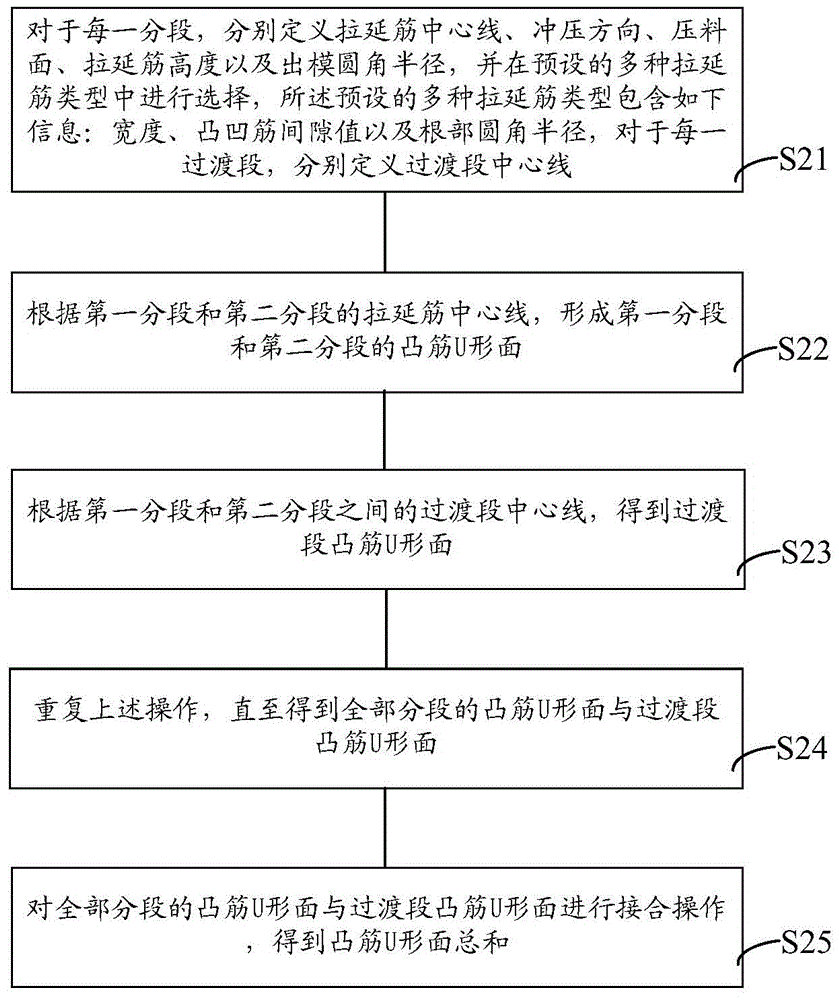

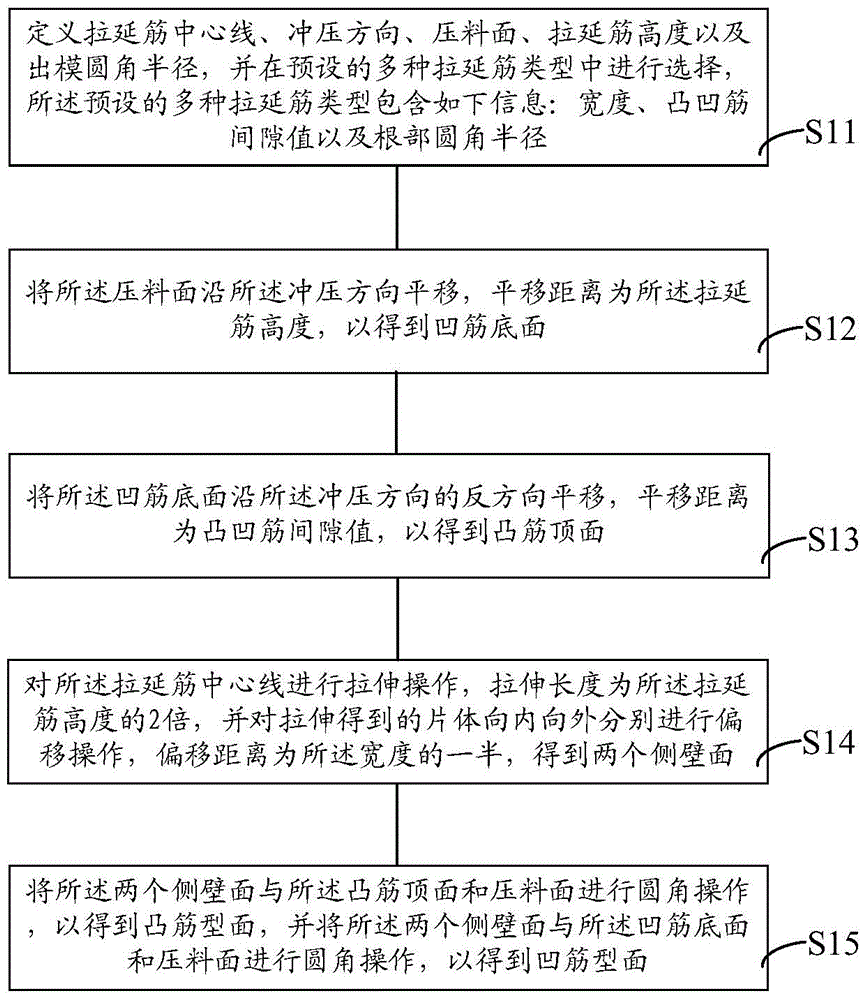

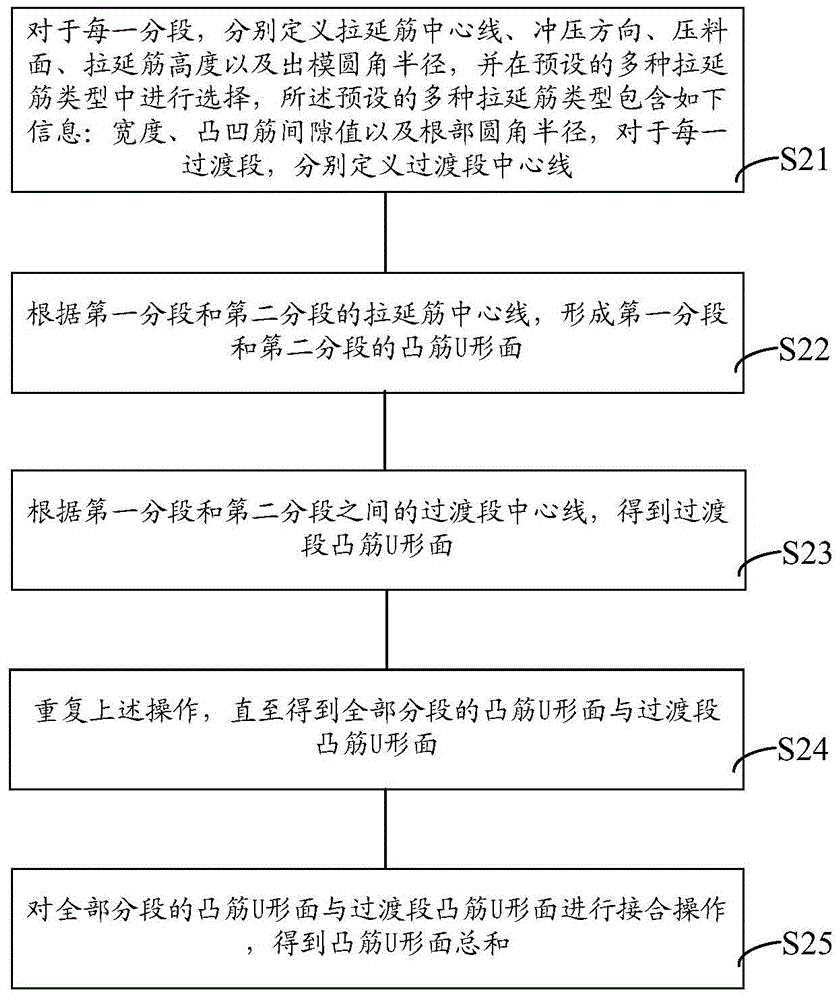

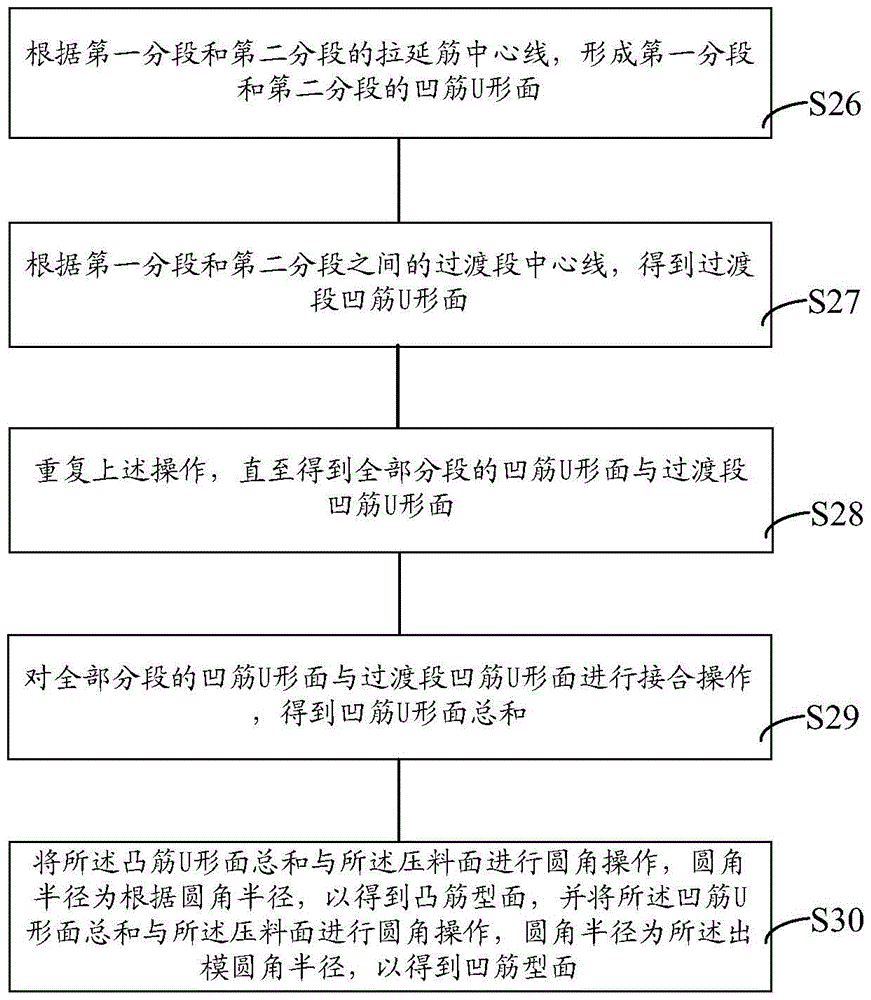

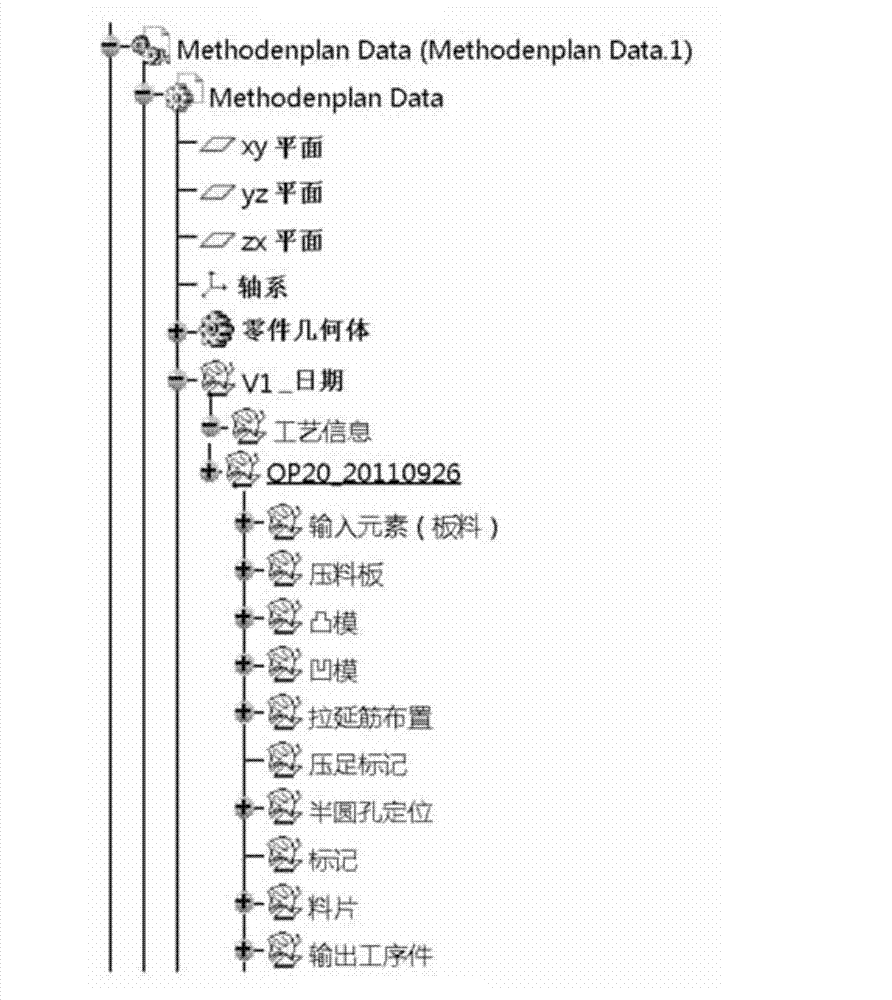

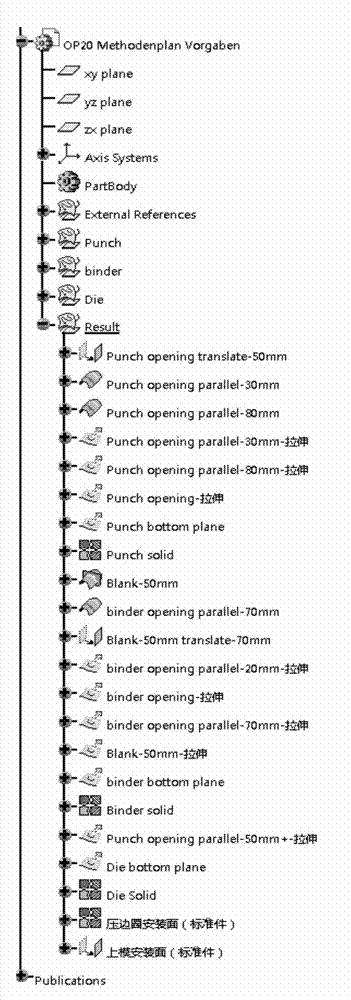

Generating method and system for stamping die brake bead and modification type brake bead

The invention provides a generating method and system for a stamping die brake bead and a modification type brake bead. The generating method of the stamping die brake bead comprises the following steps: defining a center line of the brake bead, pressing direction, binder surface, height of the brake bead and die stripping corner radius, selecting from a plurality of preset brake bead types, translating the binder surface in the pressing direction to obtain a concave brake bead bottom surface, translating the concave brake bead bottom surface in the reverse direction of the pressing direction to obtain a convex brake bead top surface, stretching the center line of the brake bead, respectively shifting the stretched sheet to outside and inside to obtain two side wall surfaces, conducting circular bead operation to the two side wall surfaces, the convex brake bead top surface and the binder surface to obtain the convex brake bead molded surface, conducting the circular bead operation to the two side wall surfaces, the concave brake bead bottom surface and the binder surface to obtain the concave brake bead molded surface. The generating method disclosed by the invention can automatically finish modeling of the brake bead according to the related parameters inputted by a user, and is favorable to shorten the design cycle and lower the cost.

Owner:SAIC VOLKSWAGEN AUTOMOTIVE CO LTD

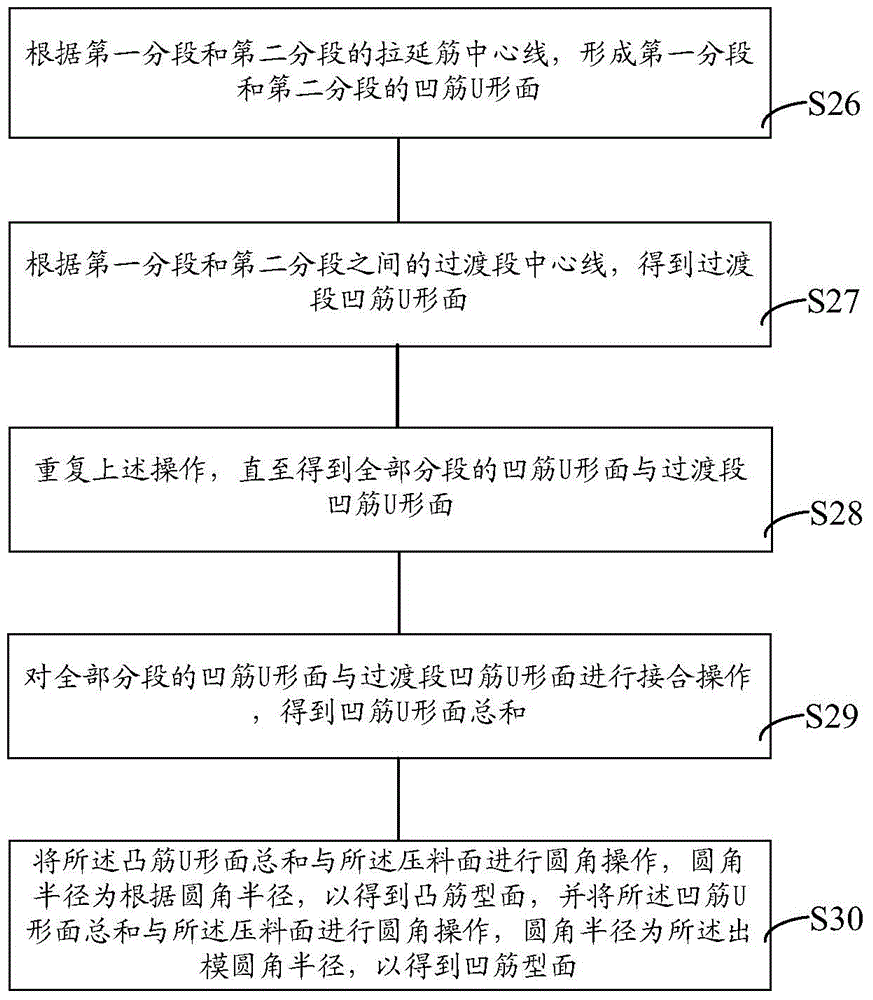

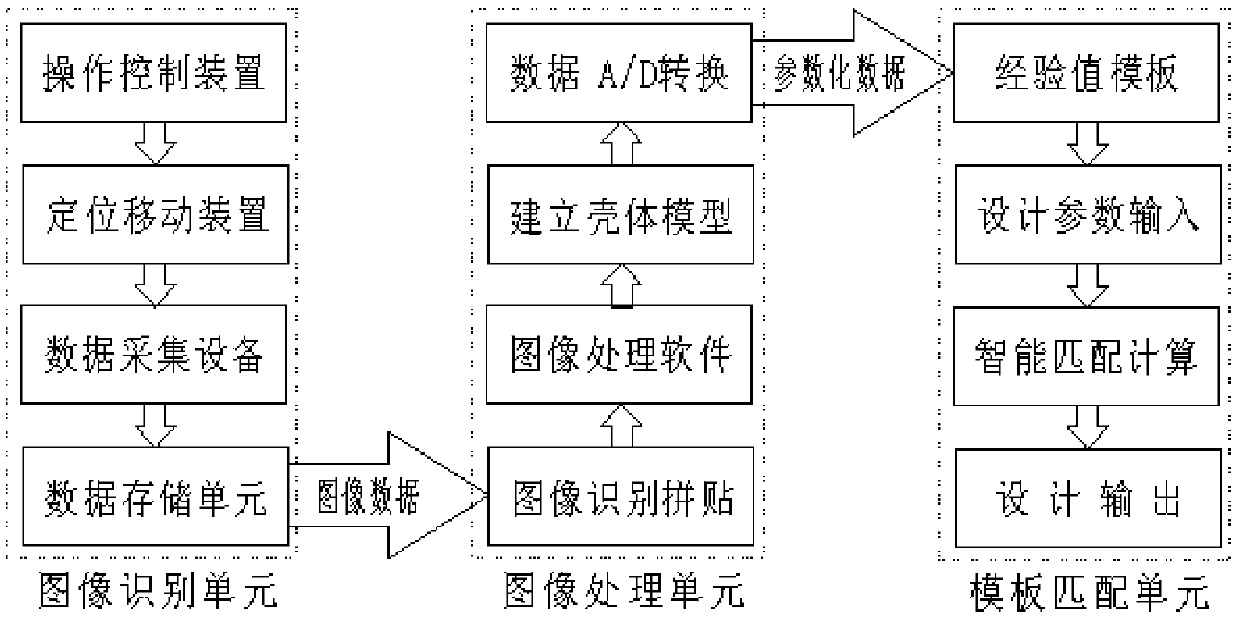

An elevator shaft design method and system based on image recognition

ActiveCN109558675AGuaranteed feasibilityGuaranteed accuracyGeometric CADCharacter and pattern recognitionGenerative DesignSimulation

The invention provides an elevator shaft design method and system based on image recognition. The method includes collecting hoistway images vertically at intervals; performing identification, splicing and A / D conversion on the images in sequence and forming a complete shell model of the maximum allowable accommodating space of the elevator hoistway; generating parameterized data by utilizing theshell model; performing smart matching between the parameterized data and a specified elevator parameter specification; if the matching is successful, outputting the elevator parameter specification as a design solution; if the matching is unsuccessful, adjusting the elevator parameter specification and then performing matching again until the matching is successful. According to the elevator parameter specification matching method and device, the personal injury accidents such as high object falling, missing stepping and shearing which are likely to happen in the operation process of personnel in the dangerous environment of the elevator hoistway are avoided, and the design scheme can be automatically generated.

Owner:GUANGDONG SUZUKI ELEVATOR

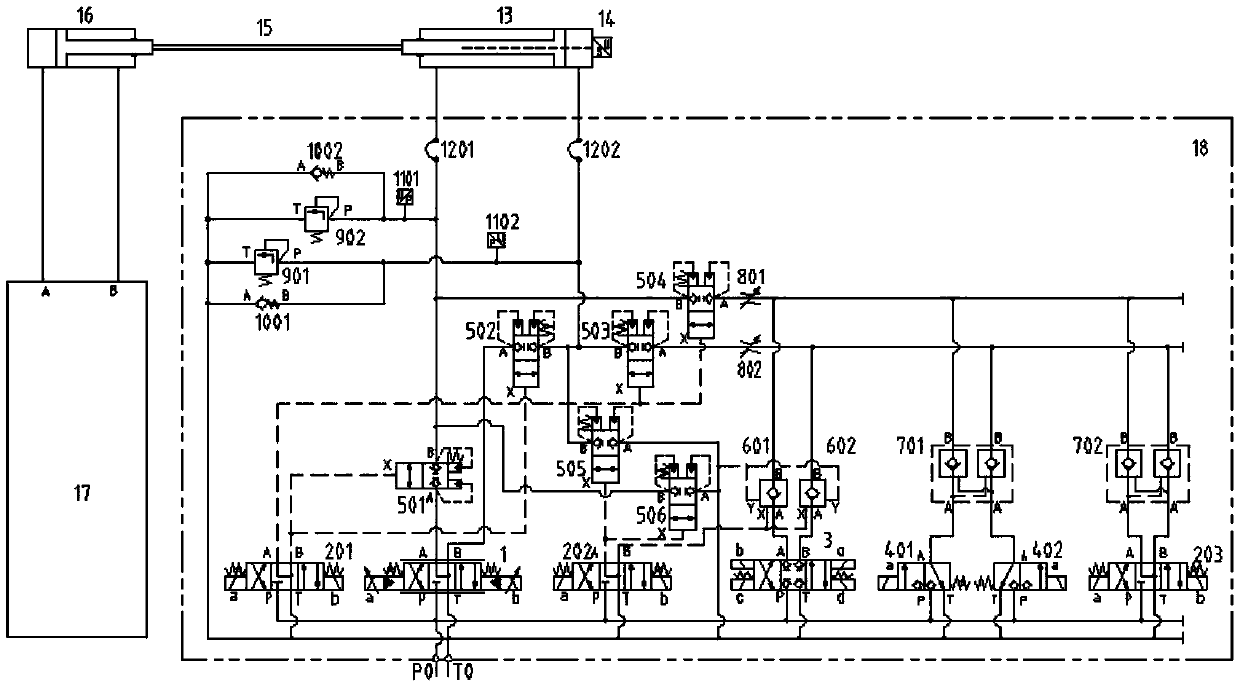

Hydraulic position and pressure closed-loop control dynamic static simulation test system and method

PendingCN110131240AReduce Design ErrorsImprove design efficiencyFluid-pressure actuator testingPistonLoop control

The invention discloses a hydraulic position and pressure closed-loop control dynamic static simulation test system and a method. The system at least comprises a dynamic static simulation test valve device (18), a test hydraulic cylinder (13), a displacement sensor (14), a connecting rod (15), a loading hydraulic cylinder (16) and a loading valve device (17), wherein the two ends of the connectingrod (15) are connected with the test hydraulic cylinder (13) and the loading hydraulic cylinder (16). The displacement sensor (14) is arranged at the other end of the test hydraulic cylinder (13), arod cavity of the loading hydraulic cylinder (16) is connected with an oil port B of the loading valve device (17), wherein a piston cavity of the loading hydraulic cylinder (16) is connected with anoil port A of the loading valve device (17). The test hydraulic cylinder (13) is connected with the dynamic static simulation test valve device (18).

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

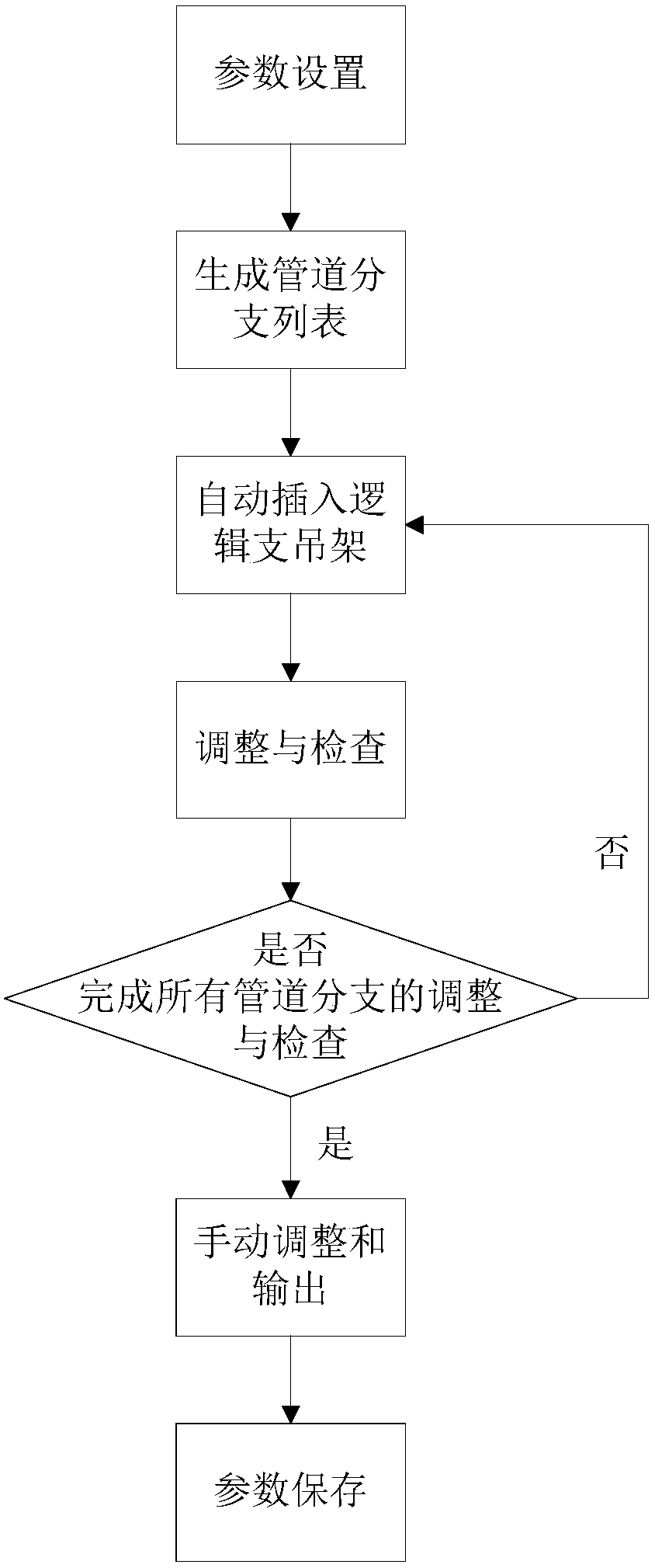

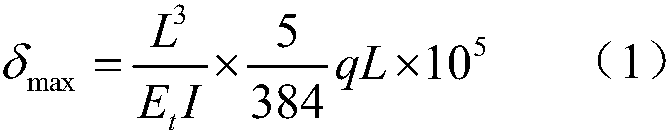

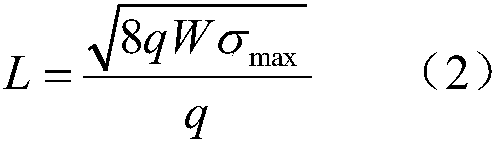

Method for automatically inserting logic supports and hangers in pipeline design

ActiveCN107844662AAutomatic insertionRealize regulationGeometric CADDesign optimisation/simulationUniform designTheoretical computer science

The invention relates to a method for automatically inserting logic supports and hangers in pipeline design. The method includes the steps of A, setting parameters, to be more specific, reading a currently optimal parameter scheme and an alternative scheme from a parameter library; B, selecting pipeline branch insertion key points to form a pipeline branch list; C, automatically inserting the automatically inserting the logic supports and hangers in each pipeline branch; D, regulating the spacing adjustment coefficients of the supports and hangers to regulate the distance between the support and hanger insertion points and adjacent elements, and inspecting each pipeline branch; E, manually regulating and outputting, to be more specific, reading the errors of each pipeline branch, and generating inspection reports; F, saving parameters, to be more specific, recalculating all parameters in the parameter setting, and generating a new optimal parameter scheme. By the method, automatic insertion, regulation and verification of the logic supports and hangers can be achieved, the design efficiency of the logic supports and hangers is increased greatly, manual design errors are reduced greatly, and a fast and uniform design scheme can be formed.

Owner:四川电力设计咨询有限责任公司

Method and system for generating drawbeads and modified drawbeads of stamping die

The invention provides a generating method and system for a stamping die brake bead and a modification type brake bead. The generating method of the stamping die brake bead comprises the following steps: defining a center line of the brake bead, pressing direction, binder surface, height of the brake bead and die stripping corner radius, selecting from a plurality of preset brake bead types, translating the binder surface in the pressing direction to obtain a concave brake bead bottom surface, translating the concave brake bead bottom surface in the reverse direction of the pressing direction to obtain a convex brake bead top surface, stretching the center line of the brake bead, respectively shifting the stretched sheet to outside and inside to obtain two side wall surfaces, conducting circular bead operation to the two side wall surfaces, the convex brake bead top surface and the binder surface to obtain the convex brake bead molded surface, conducting the circular bead operation to the two side wall surfaces, the concave brake bead bottom surface and the binder surface to obtain the concave brake bead molded surface. The generating method disclosed by the invention can automatically finish modeling of the brake bead according to the related parameters inputted by a user, and is favorable to shorten the design cycle and lower the cost.

Owner:SAIC VOLKSWAGEN AUTOMOTIVE CO LTD

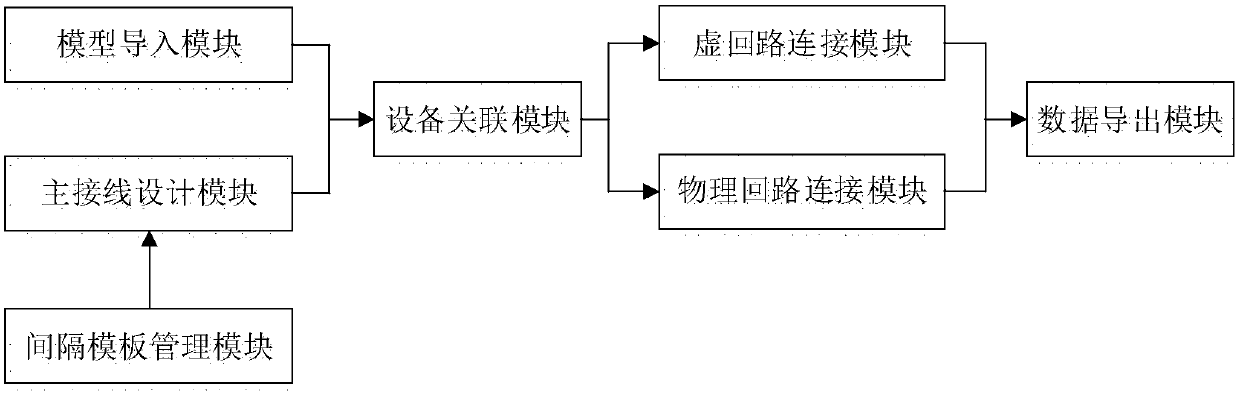

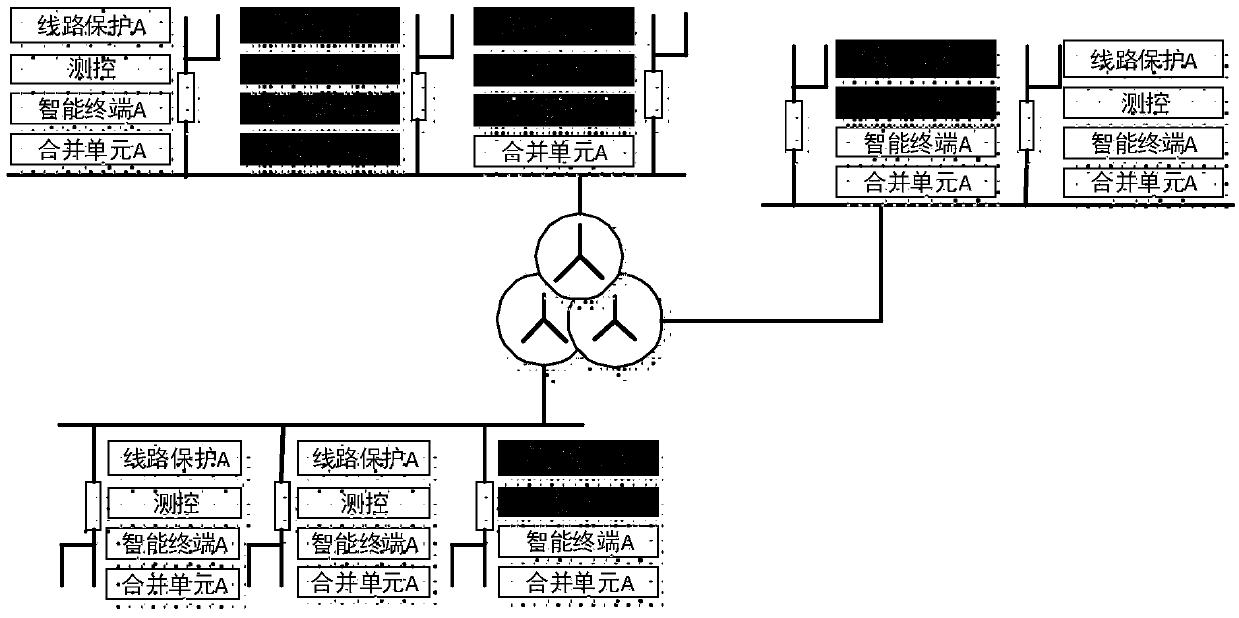

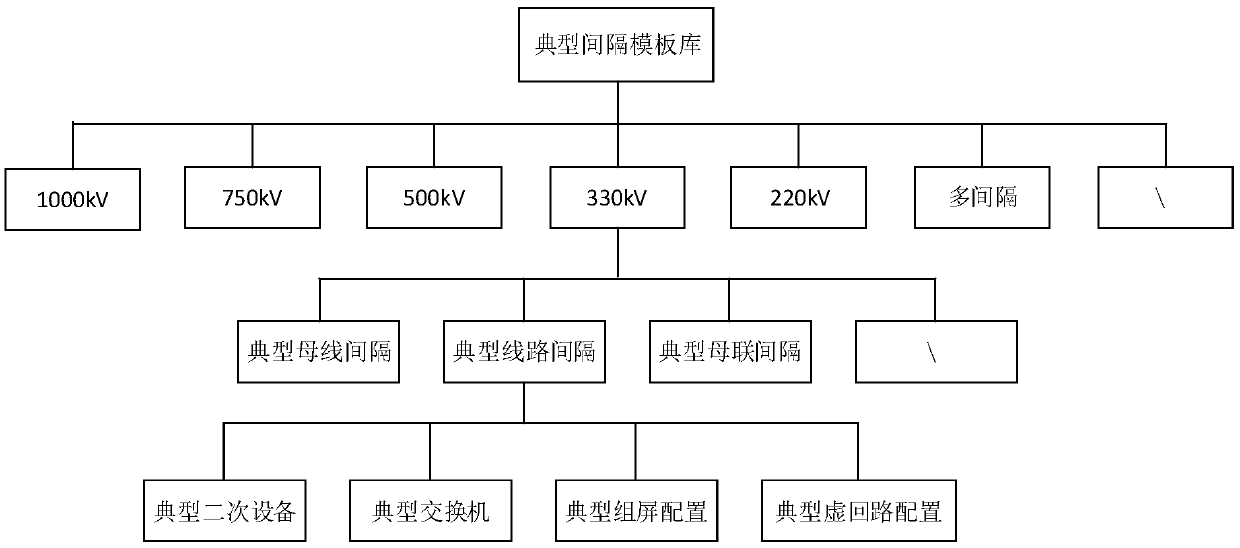

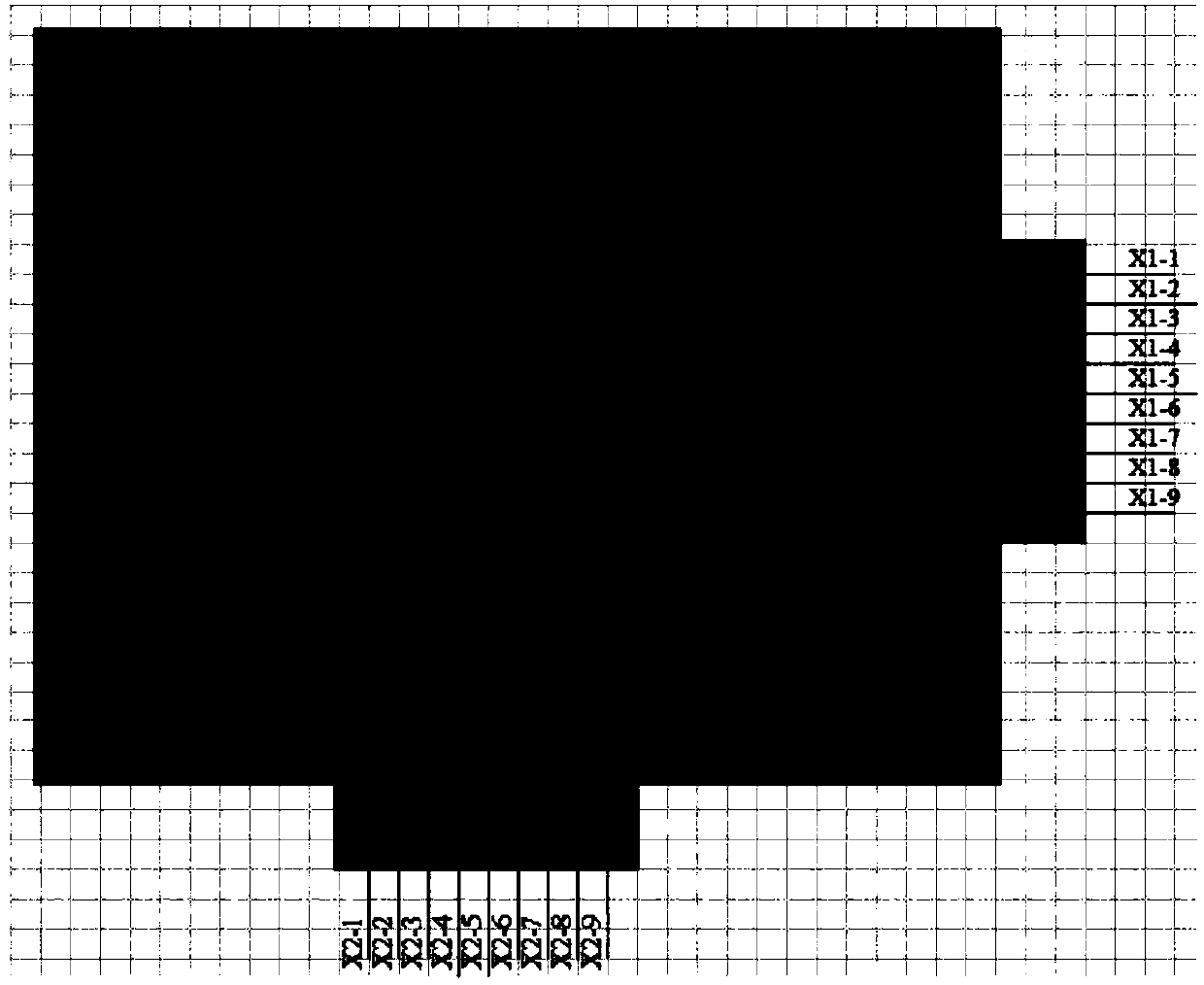

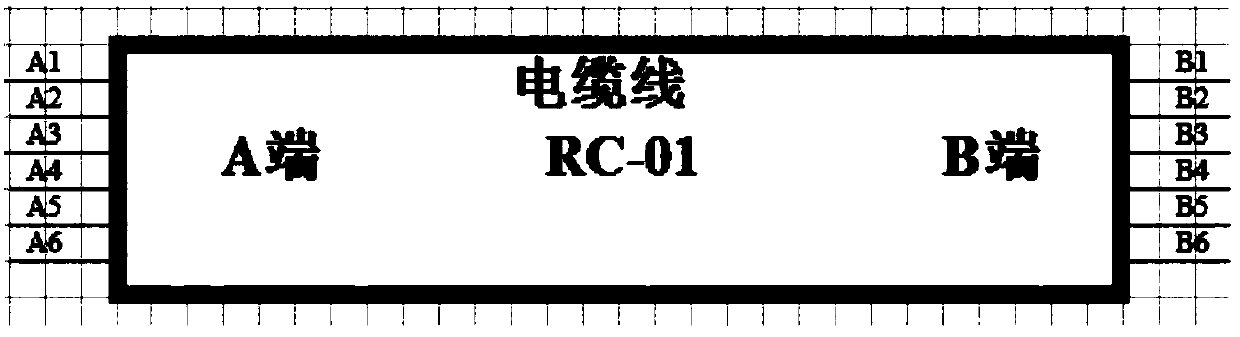

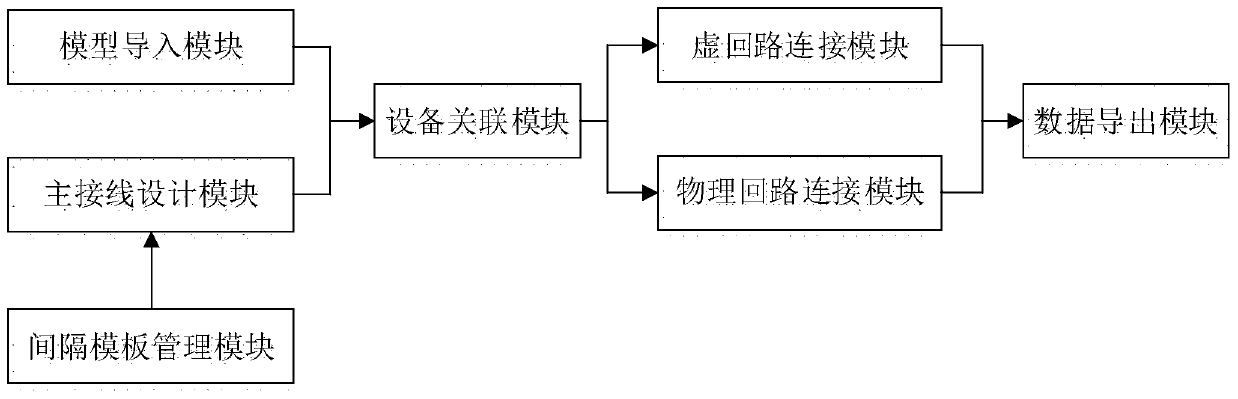

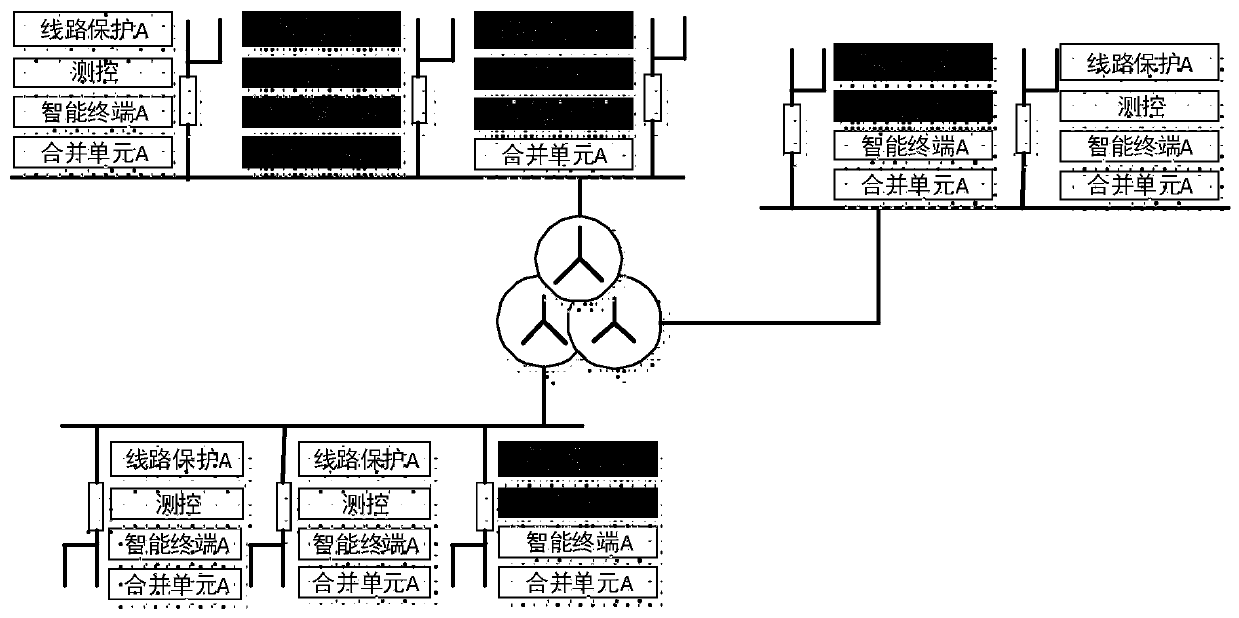

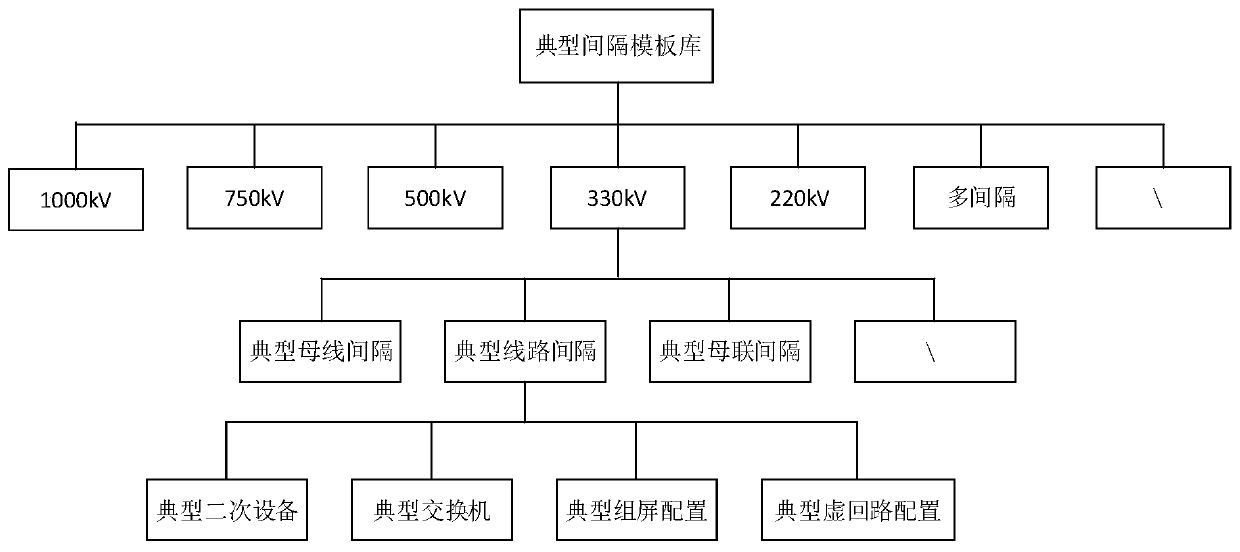

Intelligent substation secondary system rapid modeling system and method based on a main wiring diagram

ActiveCN109583068ASimple designGood graphic display capabilityDesign optimisation/simulationSpecial data processing applicationsSmart substationWiring diagram

The invention relates to an intelligent substation secondary system rapid modeling system and method based on a main wiring diagram. An intelligent substation secondary system rapid modeling system based on a main wiring diagram is characterized in that the intelligent substation secondary system rapid modeling system based on the main wiring diagram comprises an interval template management module, a model import module, an equipment association module, a virtual loop connection module, a physical loop connection module and a data export module. The method has the advantages that rapid modeling of the secondary system of the intelligent substation is completed according to the main wiring diagram, a universal data interaction format is provided, and the design efficiency and the data interaction capability of the intelligent substation are effectively improved.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER CO LTD JIAXING POWER SUPPLY CO +2

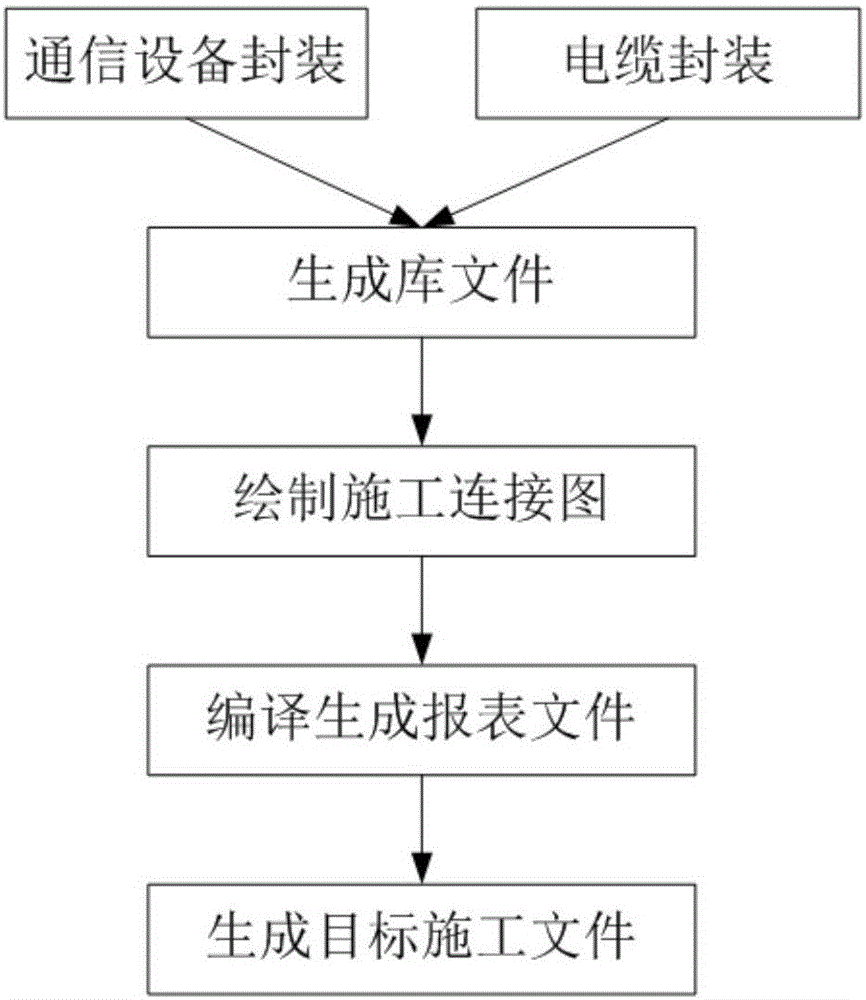

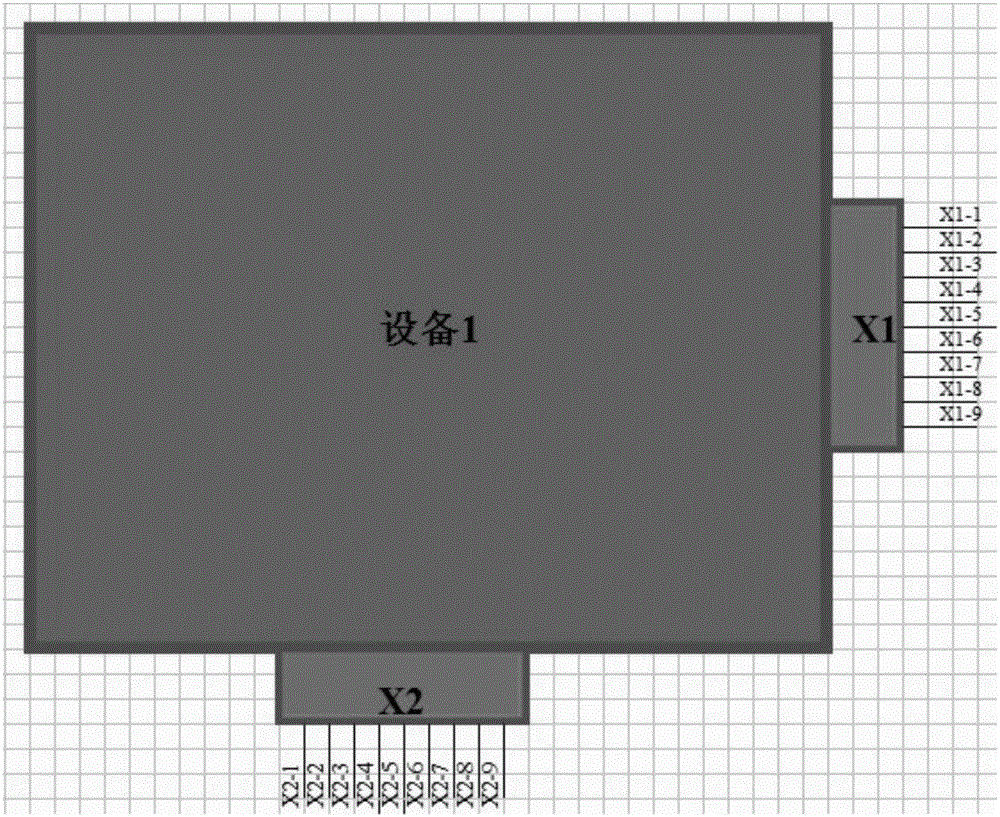

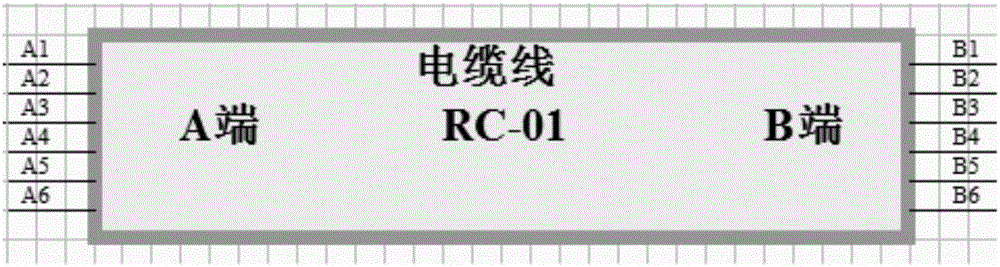

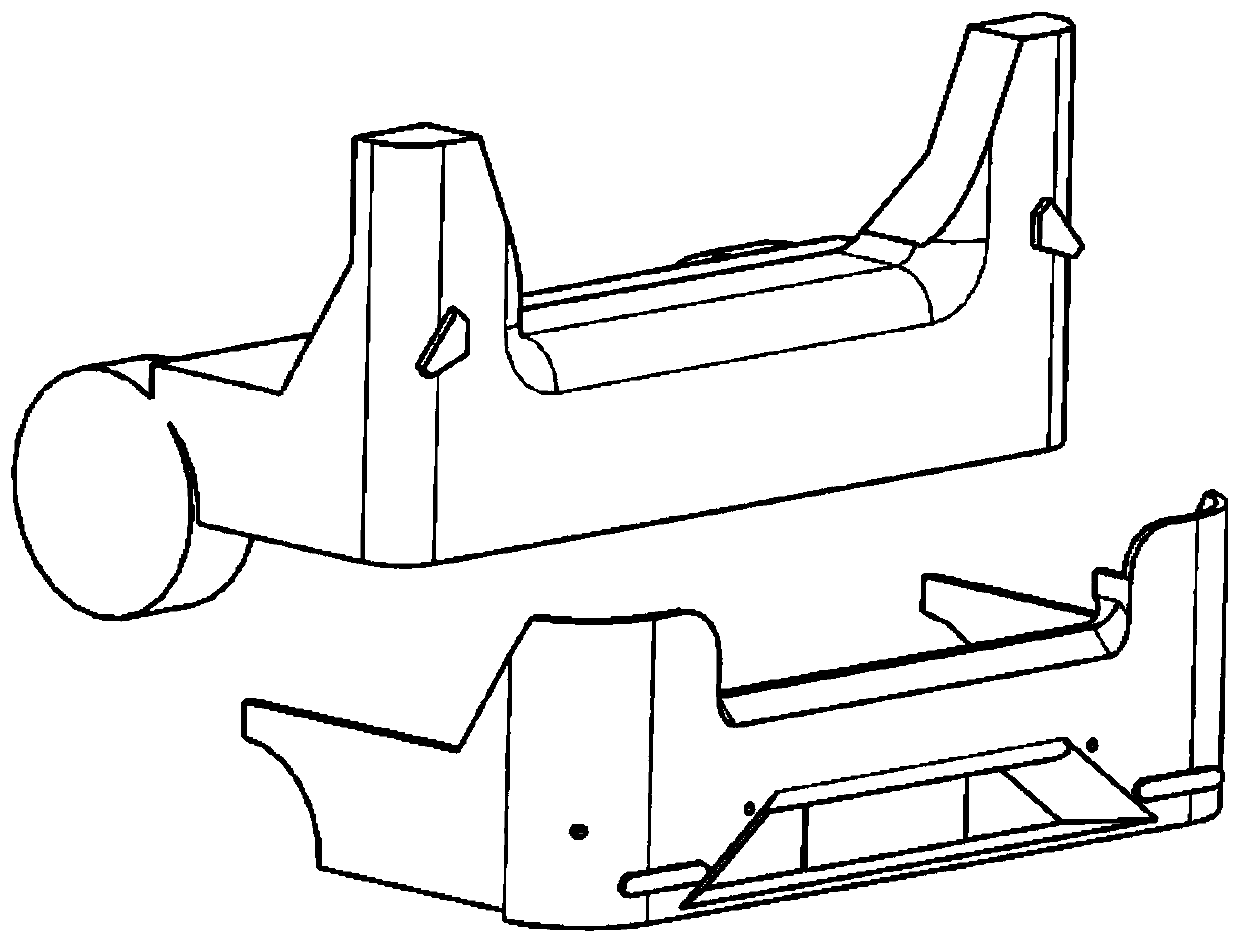

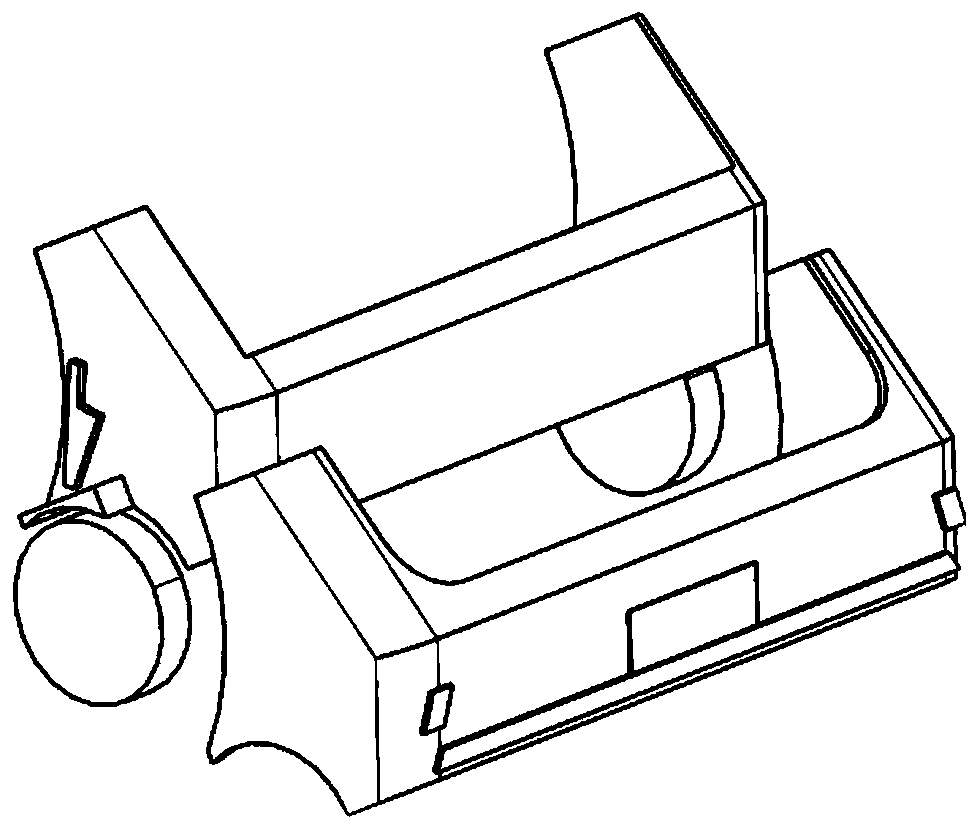

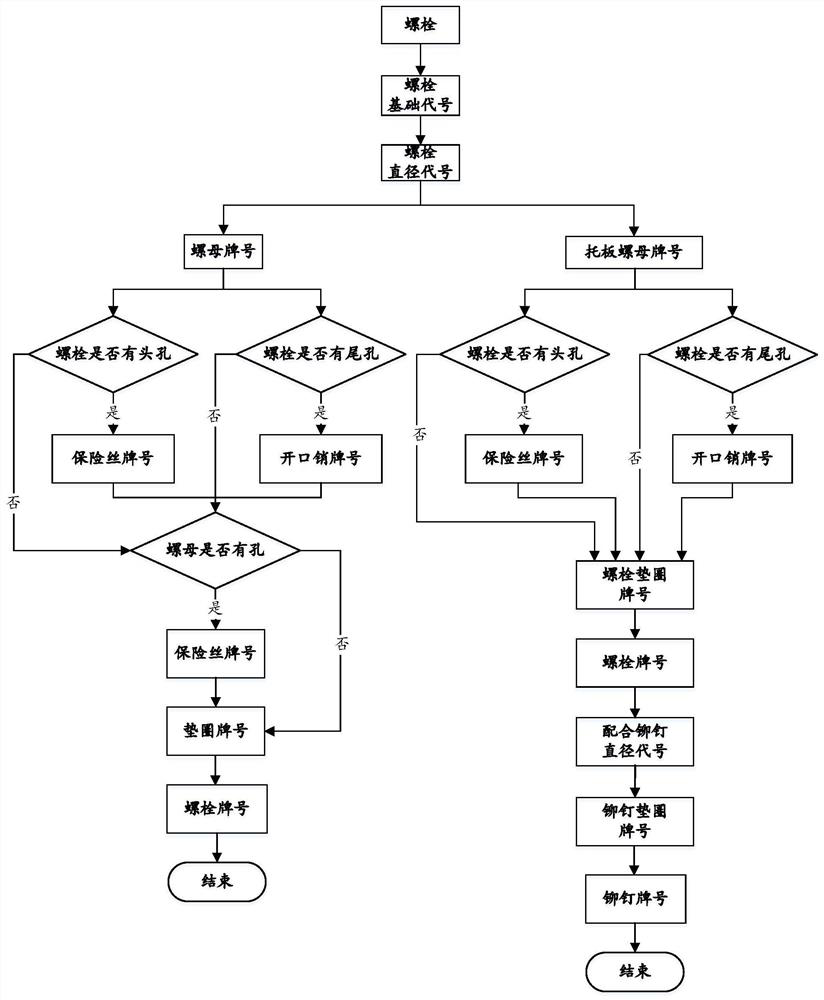

Communication system construction file visual generation method

InactiveCN106021696AEasy to drawImprove production efficiencySpecial data processing applicationsCommunications systemComputer science

The invention discloses a communication system construction file visual generation method. Based on a schematic diagram drawing function in Altium Designer software, the method comprises the following steps of 1, packaging devices and cables in a communication system, designing the devices and the cables as corresponding component units according to input and output characteristics of the devices and the cables, and importing the component units in a library file directory to form a specific device and cable library; 2, calling the packaged devices and cables to draw a construction connection diagram by a designer, and performing compilation to generate a report file corresponding to the construction connection diagram; 3, obtaining data in the construction connection diagram by analyzing the report file; and 4, generating a construction file according to the data in the construction connection diagram, and generating a word or excel form file according to a user requirement. According to the method, visual and automated editing of the construction file is realized, so that the generation efficiency of the construction file is greatly improved.

Owner:NANJING UNIV OF SCI & TECH

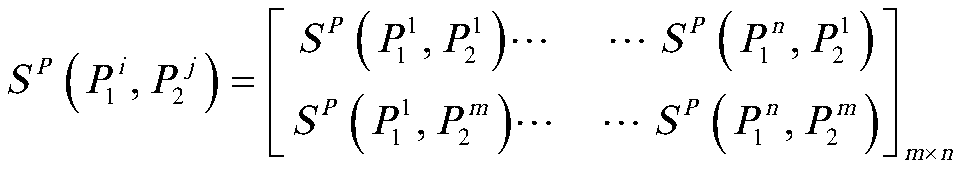

Assembly model similarity retrieval method based on spatial point set matching

InactiveCN111539485ATake advantage ofImprove efficiencyConfiguration CADCharacter and pattern recognitionDegree of similarityAttribute weight

The invention relates to an assembly model similarity retrieval method based on space point set matching, which aims at the assembly model retrieval requirement, retrieves some assembly characteristics fitting the design requirement, acquires related product information in the design and manufacturing process, and applies the product information to an assembly model to be designed. The method comprises the following steps: firstly, calculating a feature attribute similarity matrix of a selected model, and performing point multiplication with each attribute weight matrix to obtain an attributecomprehensive similarity matrix; finding effective elements of each column in the matrix, and forming a part set capable of being matched through permutation and combination; solving a spatial position similarity matrix; calculating the attribute comprehensive similarity matrix and the spatial position similarity matrix according to a formula to obtain a comprehensive similarity matrix; obtaininga model similarity matrix; summing elements at corresponding positions of the matching part set and the model similarity matrix to obtain a similarity value; wherein the value of the maximum similarity of the matching part set is the similarity between the model and the reference body.

Owner:XIAN TECH UNIV

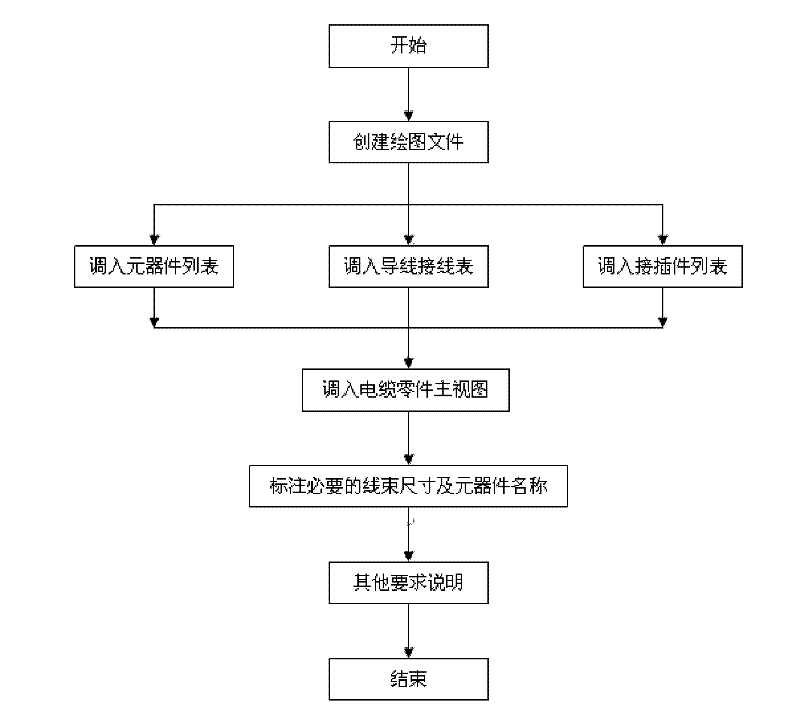

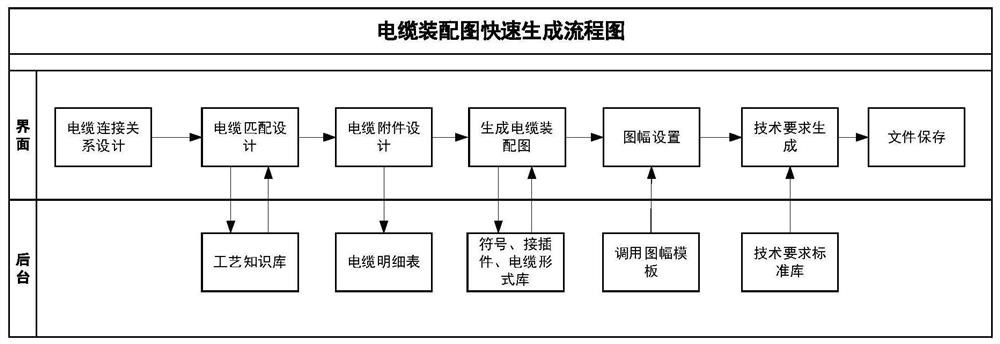

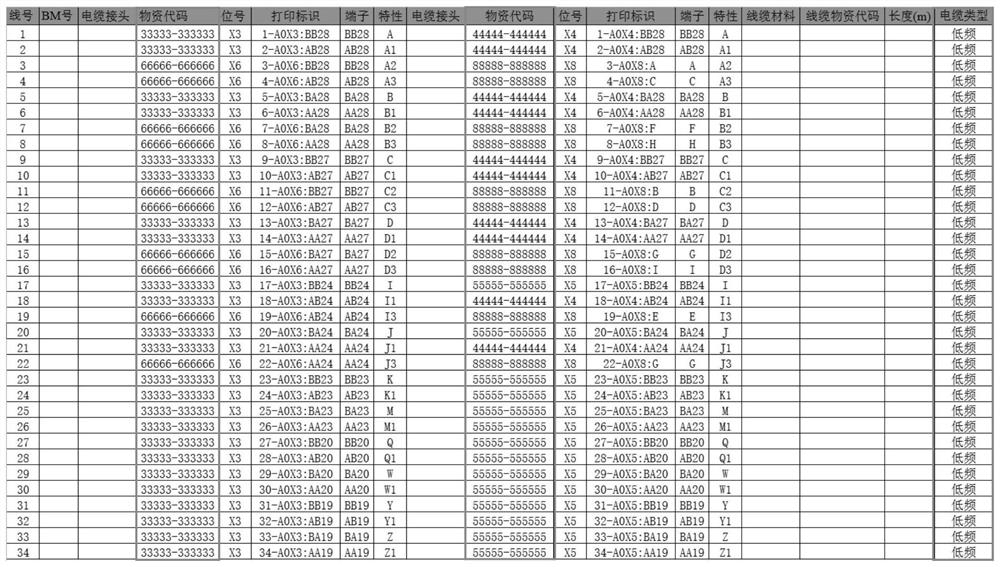

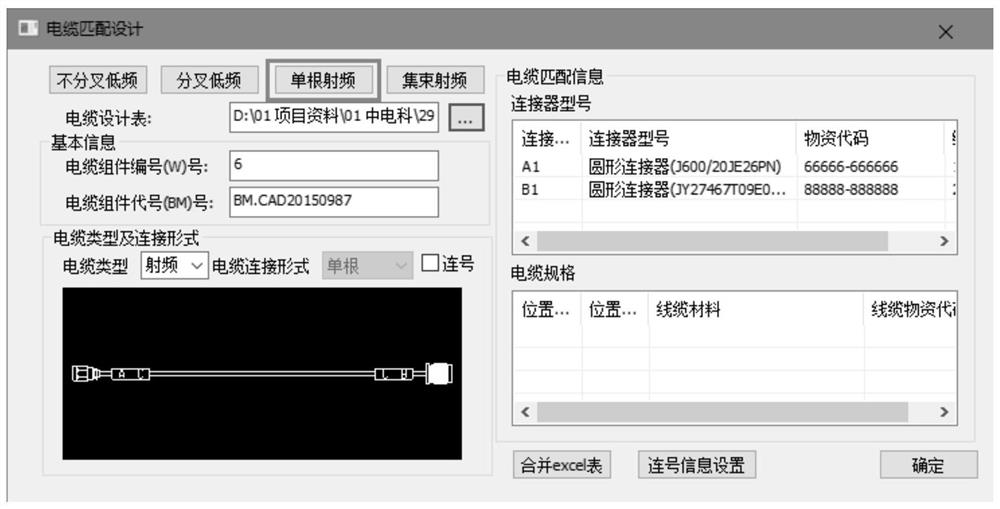

Method for quickly generating cable assembly drawing based on AutoCAD secondary development

PendingCN111709104AReduce Design ErrorsImprove design qualityGeometric CADSpecial data processing applicationsCircuit graphSoftware engineering

The invention relates to a method for quickly generating a cable assembly drawing based on AutoCAD secondary development. The method comprises the following steps: step 1, automatically extracting related information in a circuit diagram through the secondary development of AutoCAD, and generating a cable connection table; step 2, importing the cable connection table into AutoCAD, performing matching design of the cable and related parts in a cable matching design interface, and generating an incomplete cable assembly drawing, a wiring table and a printing table; and step 3, automatically popping up a cable accessory insertion interface after completing the cable matching design, reading the connector number into the interface, then selecting the accessory and completing the initial position information setting, and finally carrying out number recognition to automatically generate a complete cable assembly drawing, a wiring table and a printing table. By the adoption of the technical scheme, quick design of the cable assembly drawing of a subsystem-level product can be achieved. Design errors caused by human factors are reduced, and the design quality is improved.

Owner:SOUTHWEST CHINA RES INST OF ELECTRONICS EQUIP

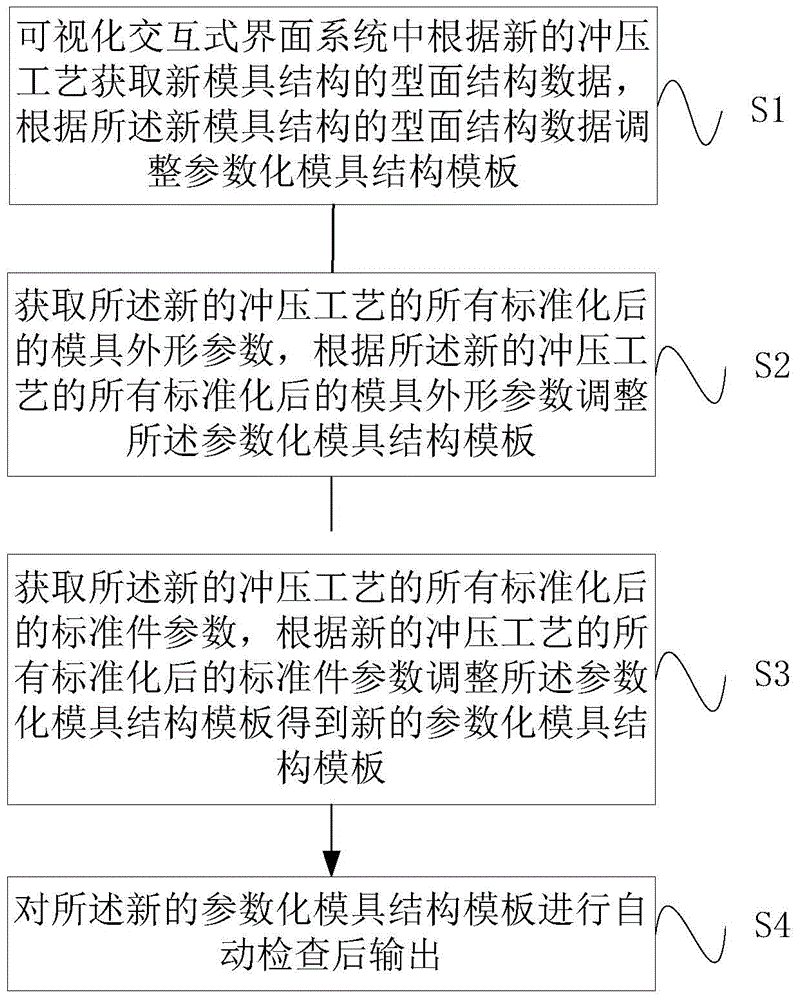

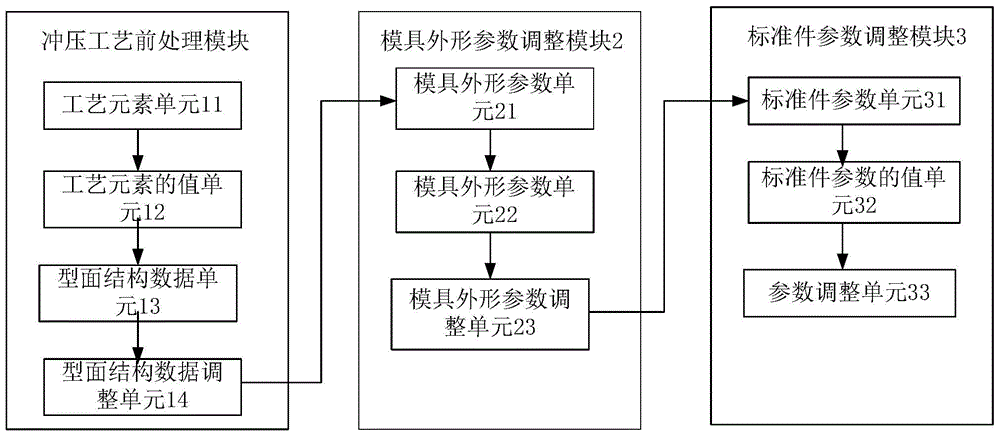

Fully parametric drawing mould design method

InactiveCN103699708AShort cycleShorten the timeSpecial data processing applicationsStamping processSolid modeling

The invention discloses a fully parametric drawing mould design method, which enables the design of a mould structure to be more reasonable and realizes the parameterization, the high speed and the intellectualization of the drawing mould design process. The invention has the technical scheme that the method comprises the following steps of stamping process pretreatment: processing process data, and directly obtaining a mould structure design element by combining with a mould design standard; mould structure design: aiming at the design of the non molded surface part of a model to carry out associated design to a mould structure parameter during solid modeling so as to bring convenience for the model to automatically change when a corresponding parameter is changed.

Owner:SAIC VOLKSWAGEN AUTOMOTIVE CO LTD

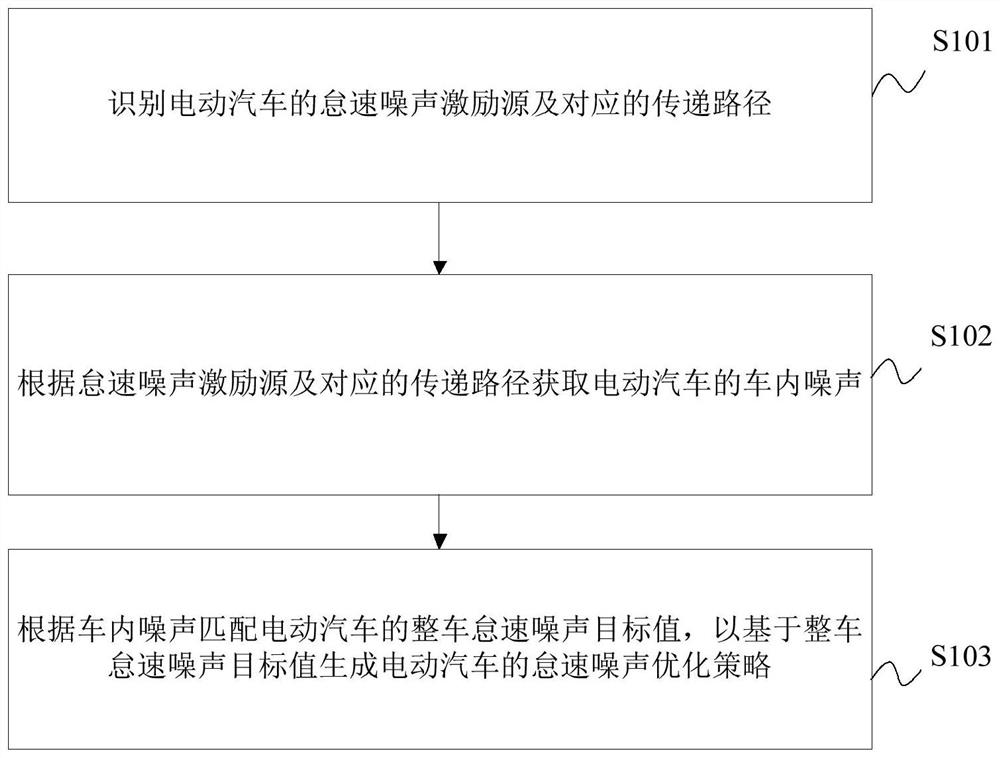

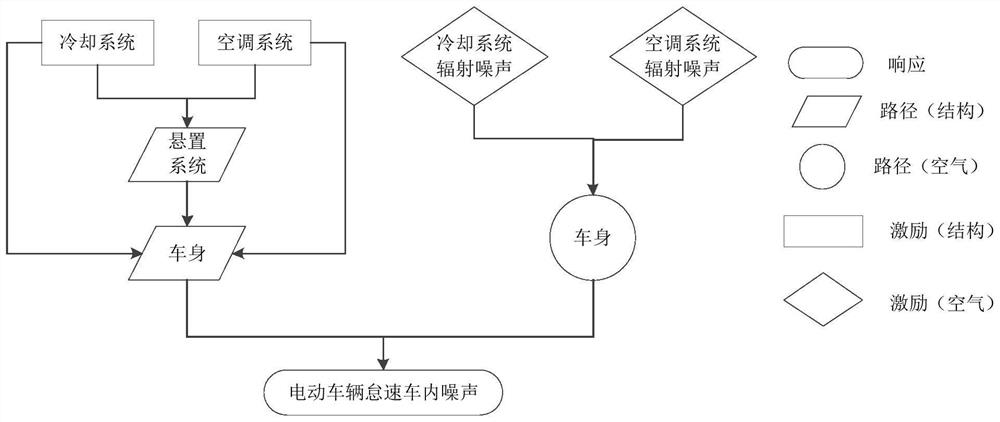

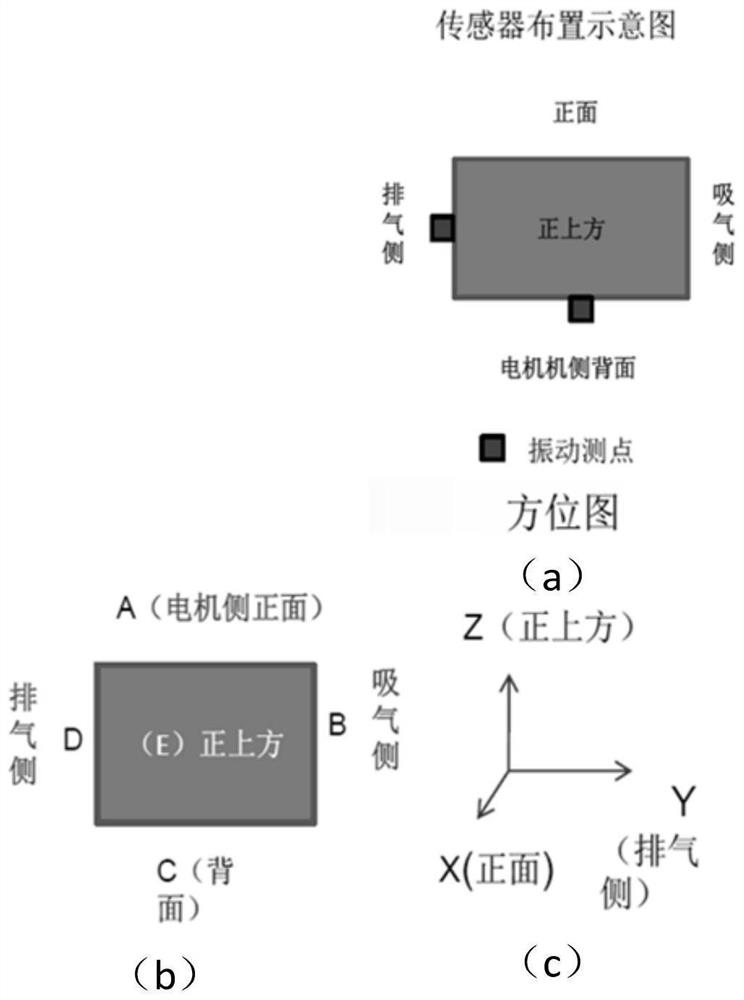

Electric vehicle idle speed noise matching method and device

PendingCN114354214AAdvantages of idling noise matching methodShorten the development cycleVehicle testingSubsonic/sonic/ultrasonic wave measurementIdle speedElectric vehicle

The invention relates to the technical field of vehicles, in particular to an electric vehicle idle speed noise matching method and device, and the method comprises the steps: recognizing an idle speed noise excitation source of an electric vehicle and a corresponding transmission path; according to the idling noise excitation source and the corresponding transmission path, the in-vehicle noise of the electric vehicle is obtained; and according to the in-vehicle noise, matching a whole vehicle idle speed noise target value of the electric vehicle, so as to generate an idle speed noise optimization strategy of the electric vehicle based on the whole vehicle idle speed noise target value. According to the method, the target value can be compared in the vehicle design stage, design errors are reduced, the vehicle development period is shortened, the later mold modification and change cost is reduced, the vehicle model development and design cost is reduced, idling noise influencing components and system indexes can be rapidly formulated, and the method is accurate and effective.

Owner:GREAT WALL MOTOR CO LTD

Interactive mold design method and system

ActiveCN103551464BHigh degree of standardizationShorten the design cycleShaping toolsDesign standardWorkload

Owner:SAIC VOLKSWAGEN AUTOMOTIVE CO LTD

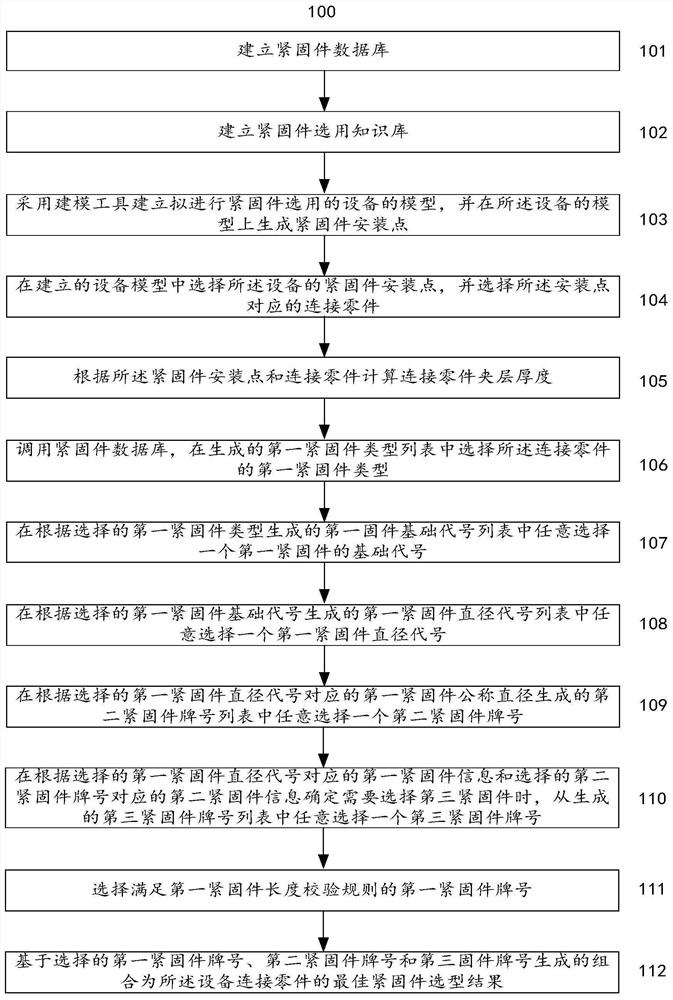

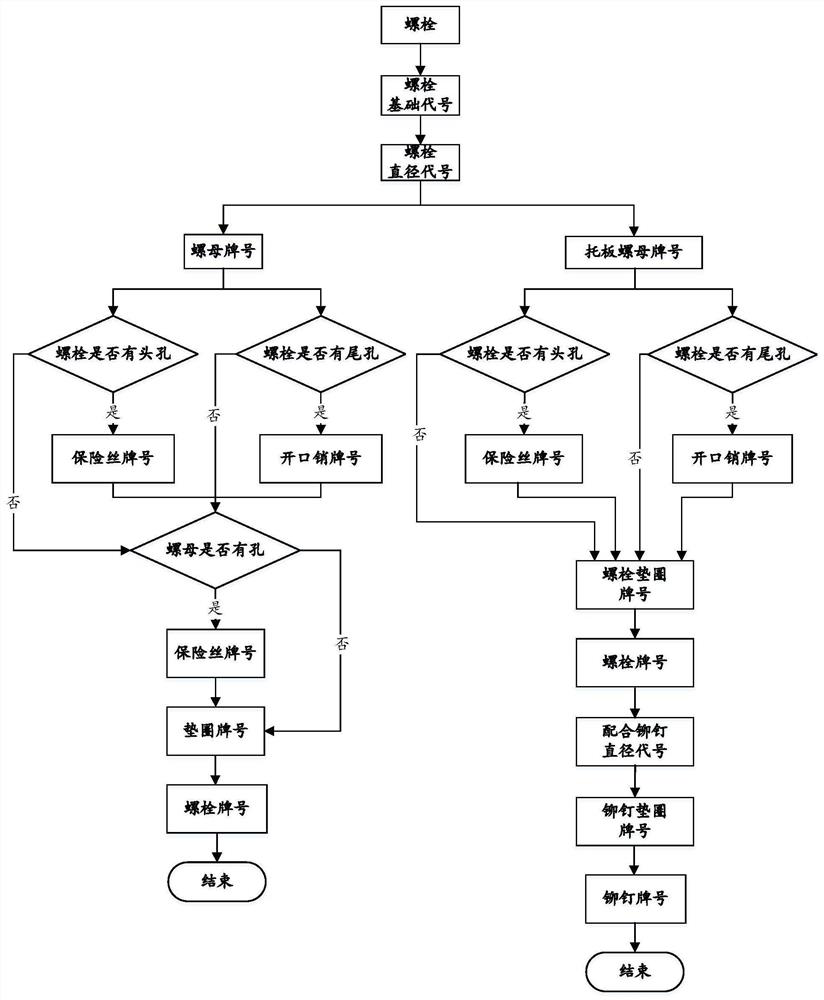

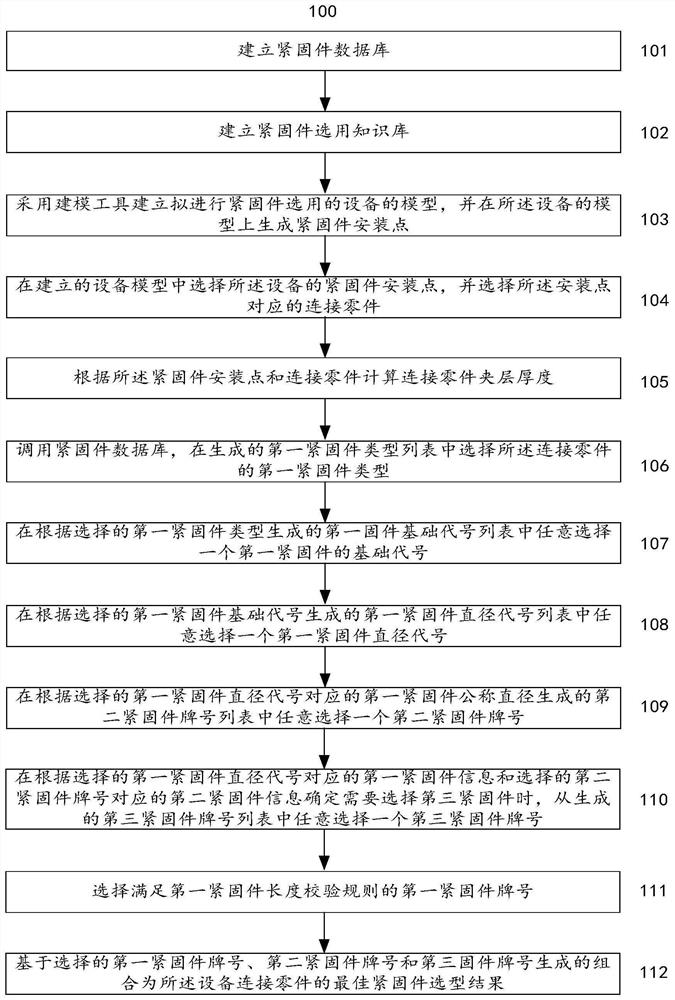

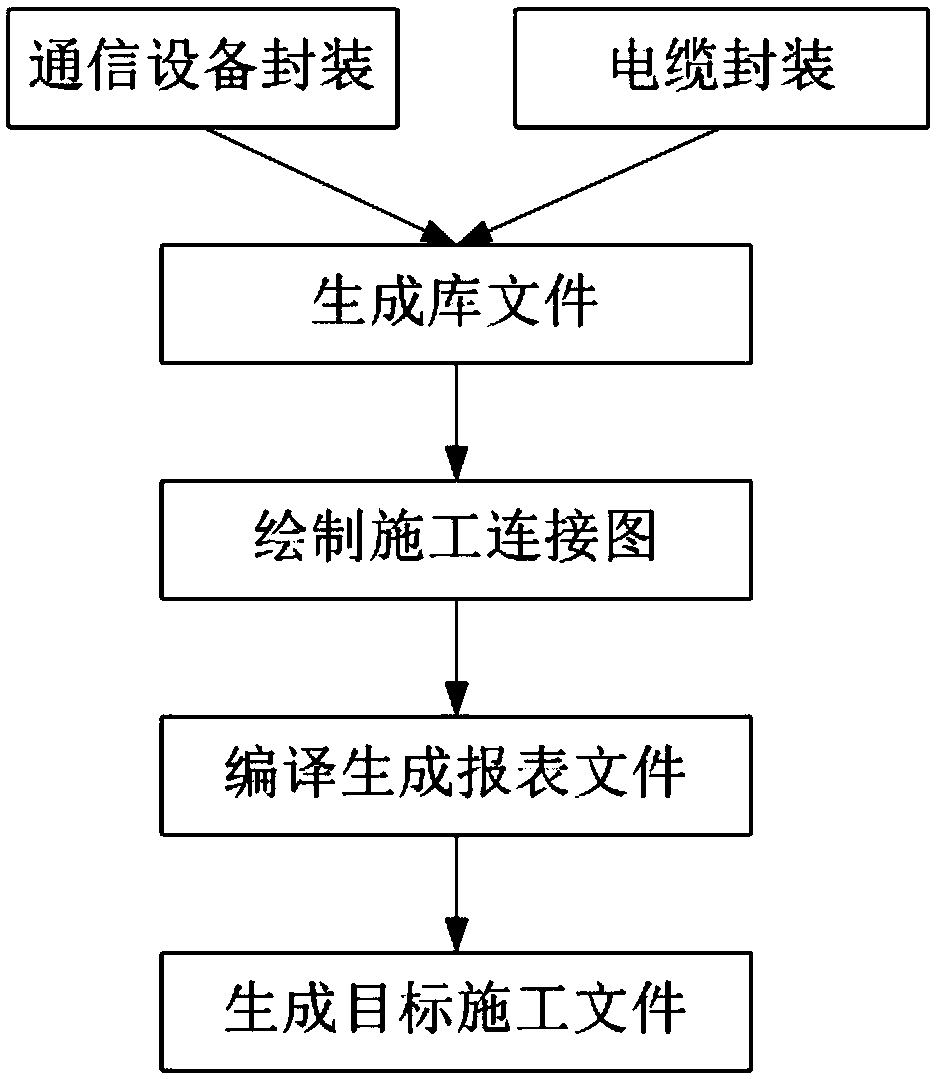

A fastener selection method and system

InactiveCN111783183AImprove efficiency in assembly designLower the thresholdGeometric CADConfiguration CADAlgorithmEngineering

The invention provides a fastener selecting method and system. Fastener information is collected in advance to establish a fastener database; and establishing a fastener selection knowledge base, solidifying the matching rule of the fastener; the method comprises the following steps: firstly, establishing a model of equipment to be used for fastener selection through a three-dimensional modeling tool; the method comprises the following steps: establishing a model, generating fastener mounting points on the model, selecting connecting parts corresponding to the mounting points, calculating theinterlayer thickness of the connecting parts, finally calling fastener data, and quickly and accurately selecting fastener combinations for fixing the mounting points according to fastener matching rules in a fastener selection knowledge base. According to the method and the system, the problem that a manual is required to be searched for fastener assembly in the past is solved; by means of the traditional mode that fastener marks depend on experience, fastener combinations are automatically and intelligently selected on the basis of a fastener database and a knowledge base, the efficiency offastener assembly design is greatly improved, the threshold of fastener assembly design is lowered, and design errors are reduced.

Owner:BEIJING RAINFE TECH

Method and system for selecting fasteners

ActiveCN113158277BImprove efficiency in assembly designLower the thresholdGeometric CADConfiguration CADComputer scienceIndustrial engineering

The invention provides a method and system for selecting fasteners, which collects fastener information in advance to establish a fastener database, and establishes a fastener selection knowledge base. Establish a model of the equipment to be selected for fasteners, then generate fastener installation points on the model, select the connection parts corresponding to the installation points, calculate the interlayer thickness of the connection parts, and finally call the fastening According to the fastener matching rules in the fastener selection knowledge base, the fastener combination of the fixed installation point can be quickly and accurately selected. The method and system get rid of the need to search manuals for fastener assembly in the past, and select fastener grades relying on experience in the traditional mode, and realize the automatic and intelligent selection of fastener combinations based on fastener database and knowledge base, which greatly improves the fastening efficiency. The efficiency of fastener assembly design is improved, the threshold of fastener assembly design is lowered, and design errors are reduced.

Owner:BEIJING RAINFE TECH

A visualization method for generating construction documents of communication system

InactiveCN106021696BEasy to drawImprove production efficiencySpecial data processing applicationsCommunications systemComputer science

The invention discloses a communication system construction file visual generation method. Based on a schematic diagram drawing function in Altium Designer software, the method comprises the following steps of 1, packaging devices and cables in a communication system, designing the devices and the cables as corresponding component units according to input and output characteristics of the devices and the cables, and importing the component units in a library file directory to form a specific device and cable library; 2, calling the packaged devices and cables to draw a construction connection diagram by a designer, and performing compilation to generate a report file corresponding to the construction connection diagram; 3, obtaining data in the construction connection diagram by analyzing the report file; and 4, generating a construction file according to the data in the construction connection diagram, and generating a word or excel form file according to a user requirement. According to the method, visual and automated editing of the construction file is realized, so that the generation efficiency of the construction file is greatly improved.

Owner:NANJING UNIV OF SCI & TECH

System and method for rapid modeling of secondary system of intelligent substation based on main wiring diagram

ActiveCN109583068BSimple designGood graphic display capabilityDesign optimisation/simulationSpecial data processing applicationsSmart substationWiring diagram

Owner:STATE GRID ZHEJIANG ELECTRIC POWER CO LTD JIAXING POWER SUPPLY CO +2

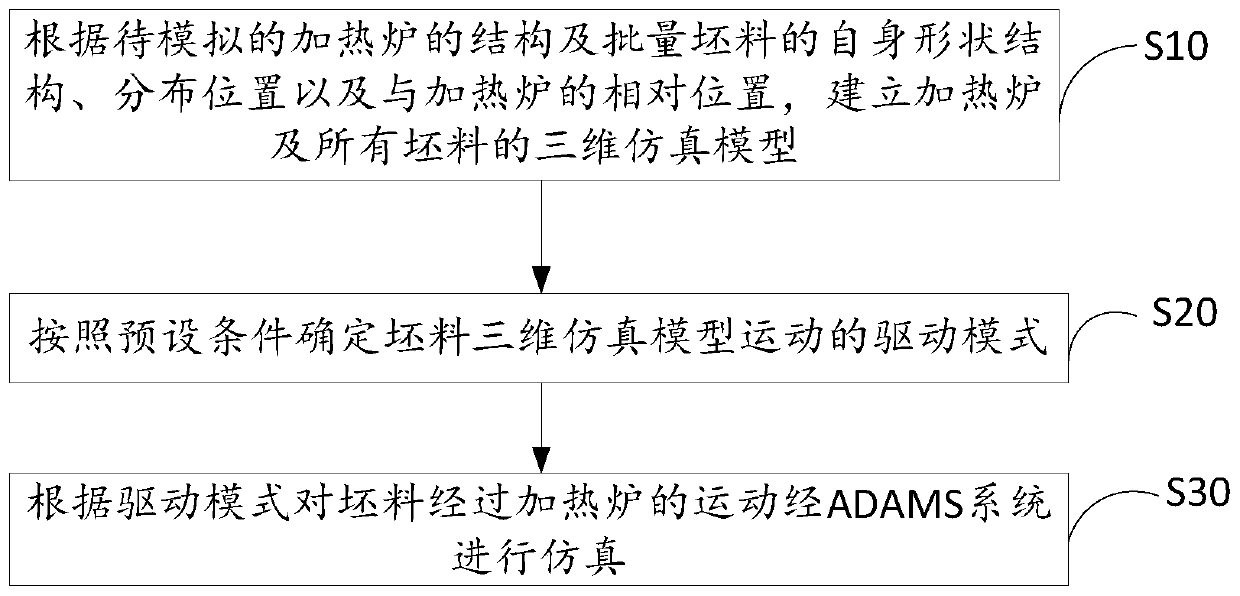

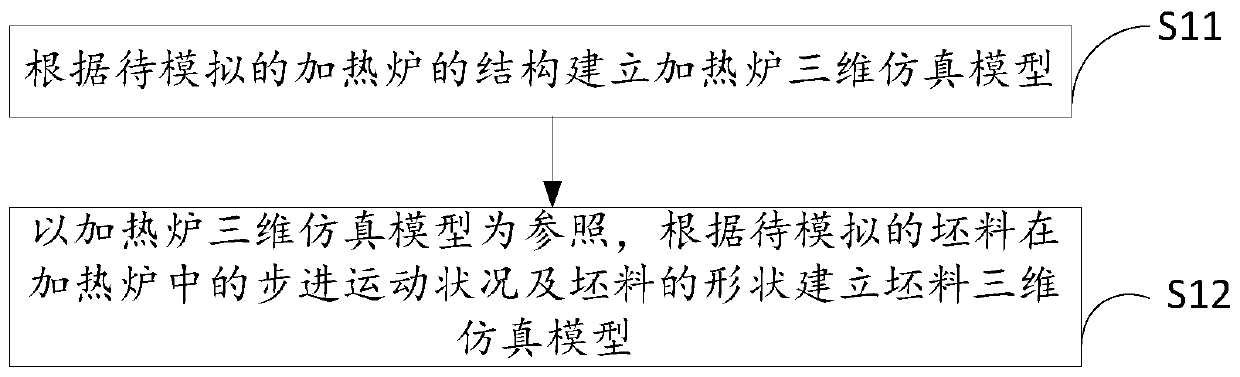

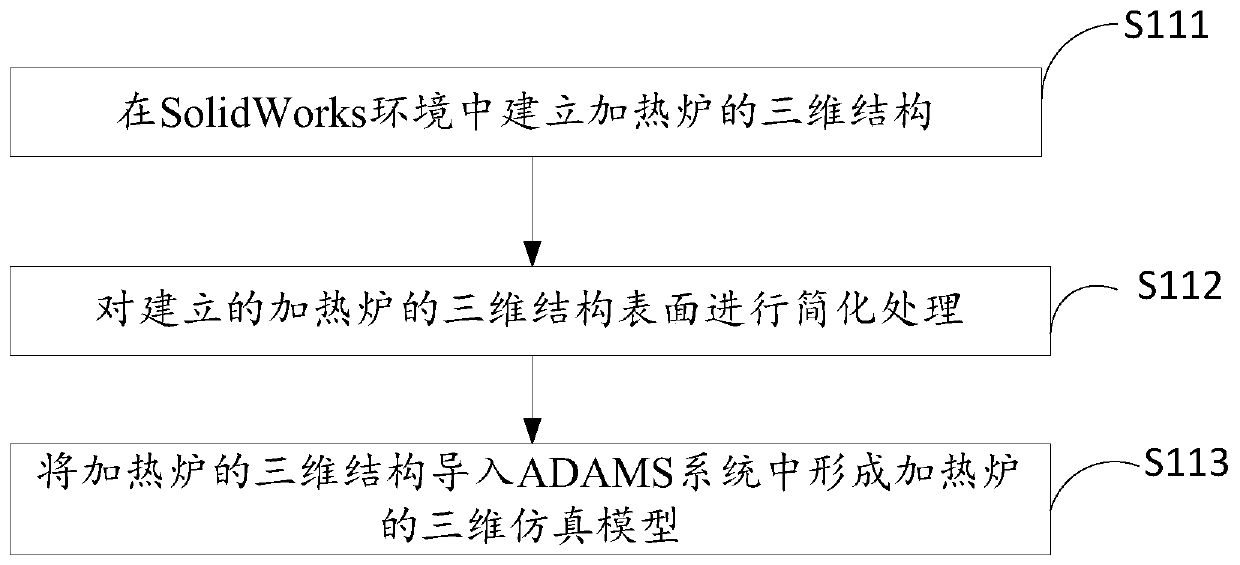

Motion Simulation Method of Heating Furnace Blank

ActiveCN106599512BEasy to operateReduce Design ErrorsDesign optimisation/simulationSpecial data processing applicationsThermodynamicsDimensional simulation

The invention provides a blank motion simulation method for a heating furnace. The method comprises the steps of: a structure of a heating furnace to be simulated, shape structures and distribution positions of batched blanks and relative positions of the batched blanks to the heating furnace, establishing a three-dimensional simulation model of the heating furnace and all the blanks; according to preset conditions, determining a driving mode of motion of the blank three-dimensional simulation model; and according to the driving mode, carrying out simulation on motion of the blanks, which is generated by the heating furnace, by ADAMS (Automatic Dynamic Analysis of Mechanical Systems). According to the scheme, the problems of high experiment cost and long period in the prior art can be solved, simulation on motion of the blanks is implemented, experiment cost is reduced, and the experiment period is shortened.

Owner:CENT SOUTH UNIV

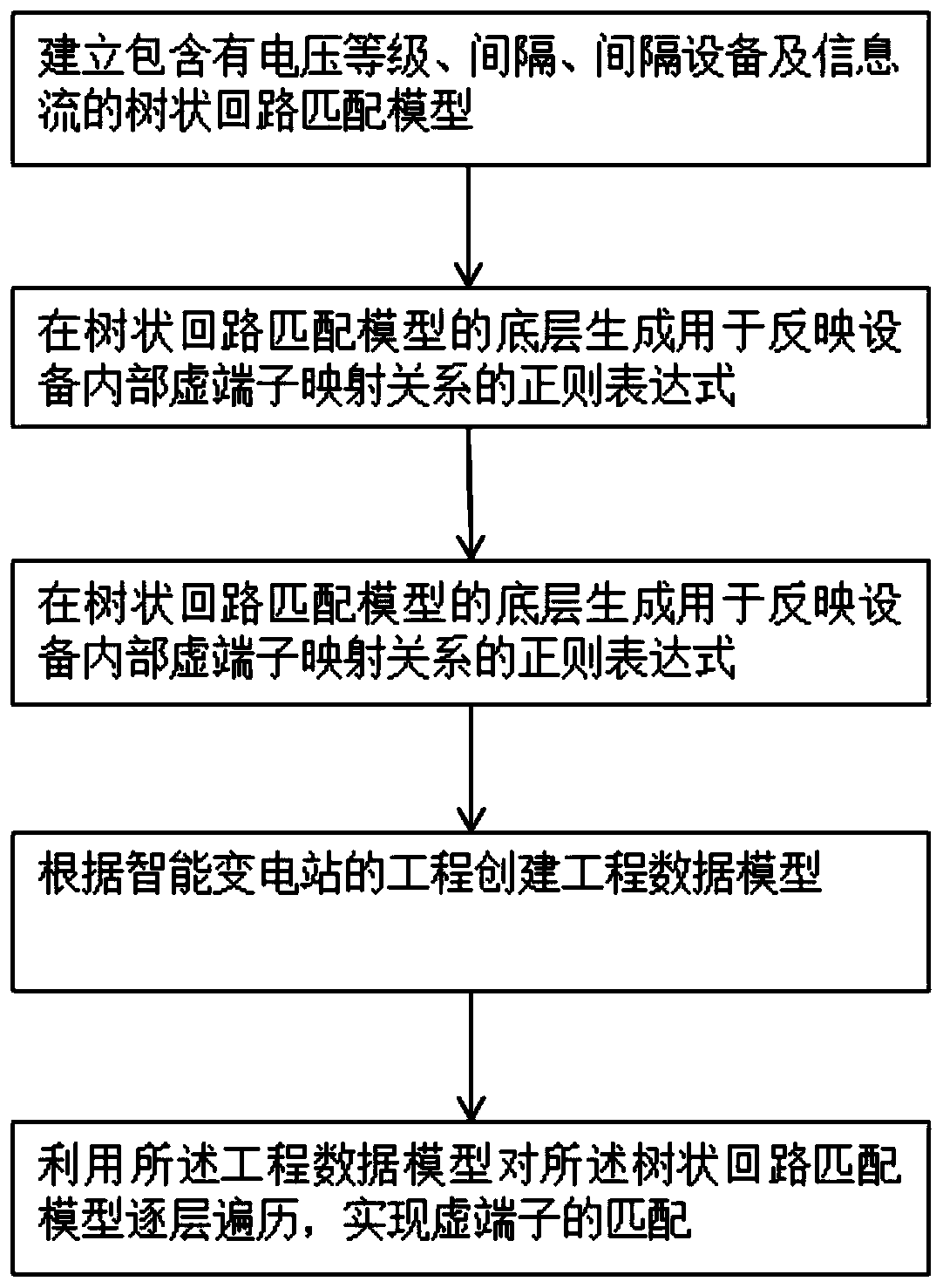

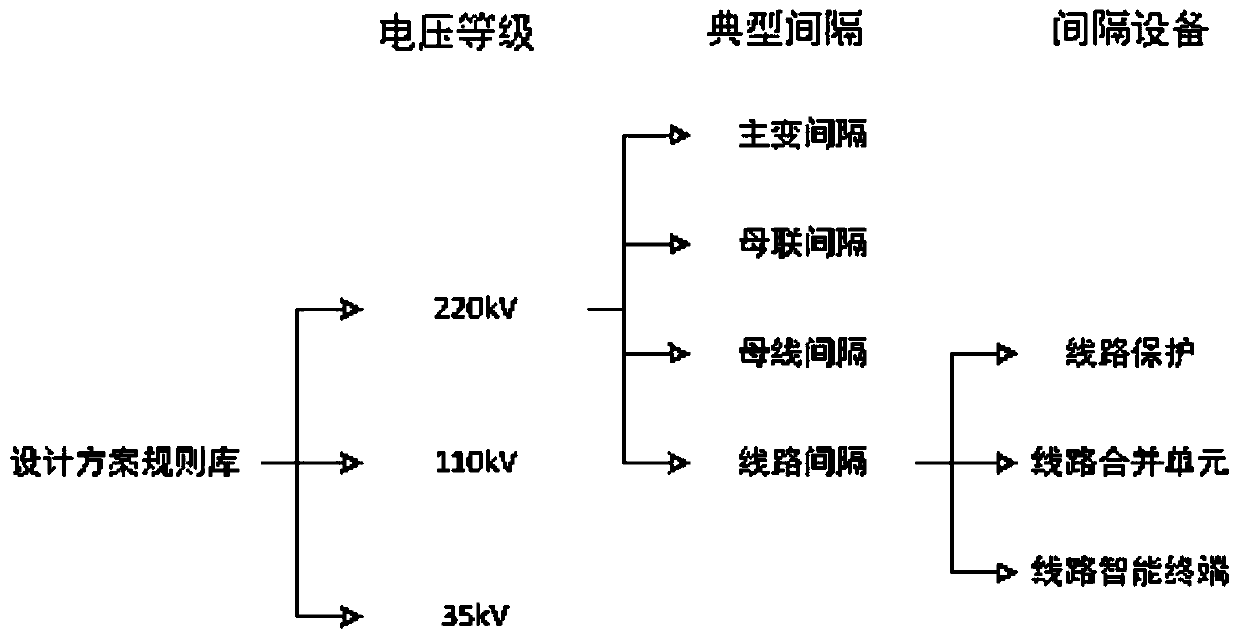

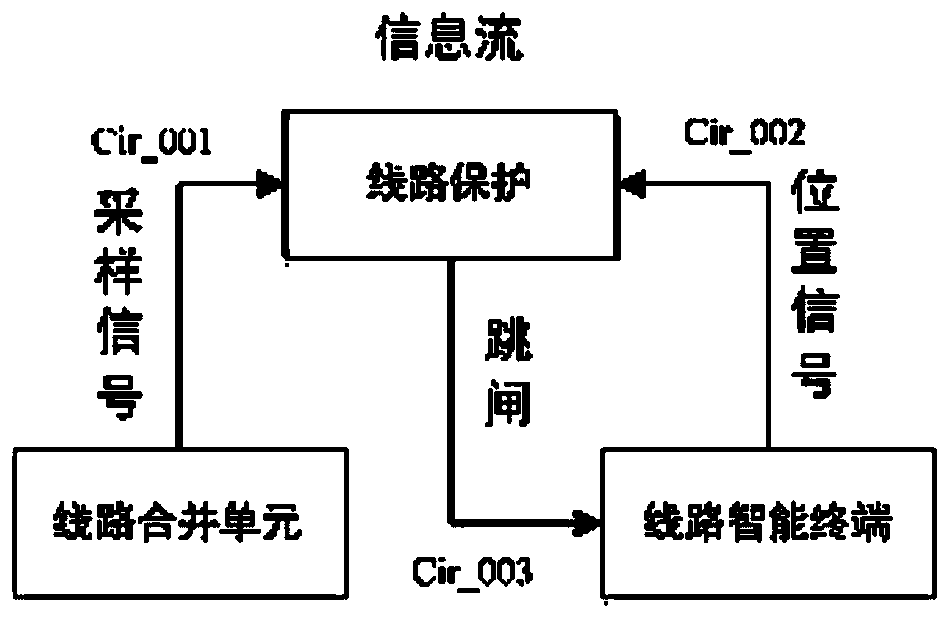

Automatic connection method of virtual circuit in smart substation

ActiveCN107025329BImprove design efficiencyEasy to reuseDesign optimisation/simulationCAD circuit designVirtual terminalSmart substation

The invention relates to the technical field of the design of a virtual circuit of an intelligent substation, and particularly relates to an automatic connecting method for the virtual circuit of the intelligent substation. The automatic connecting method comprises the following steps: typing a typical technical scheme on a technical manual in a computer, and generating a tree circuit matching model comprising voltage class, interval, interval equipment and information flow; generating a regular expression on the bottom layer of the tree circuit matching model according to the information flow and a configuration file described by a manufacturer on a virtual terminal in the interval equipment; creating an intelligent substation secondary design software according to the project of the intelligent substation; traversing the tree circuit matching model layer by layer by utilizing the intelligent substation secondary design software, matching all the regular expressions and the virtual terminal of the intelligent substation secondary design software, and connecting the successfully matched virtual terminal. The tree circuit matching model digitized by the computer is applied to the intelligent substation secondary design software, the corresponding virtual terminal in the intelligent substation secondary design software is automatically connected according to the matching result of the regular expression, and the design efficiency of the virtual circuit is greatly improved.

Owner:HUBEI ELECTRIC ENG CORP +1

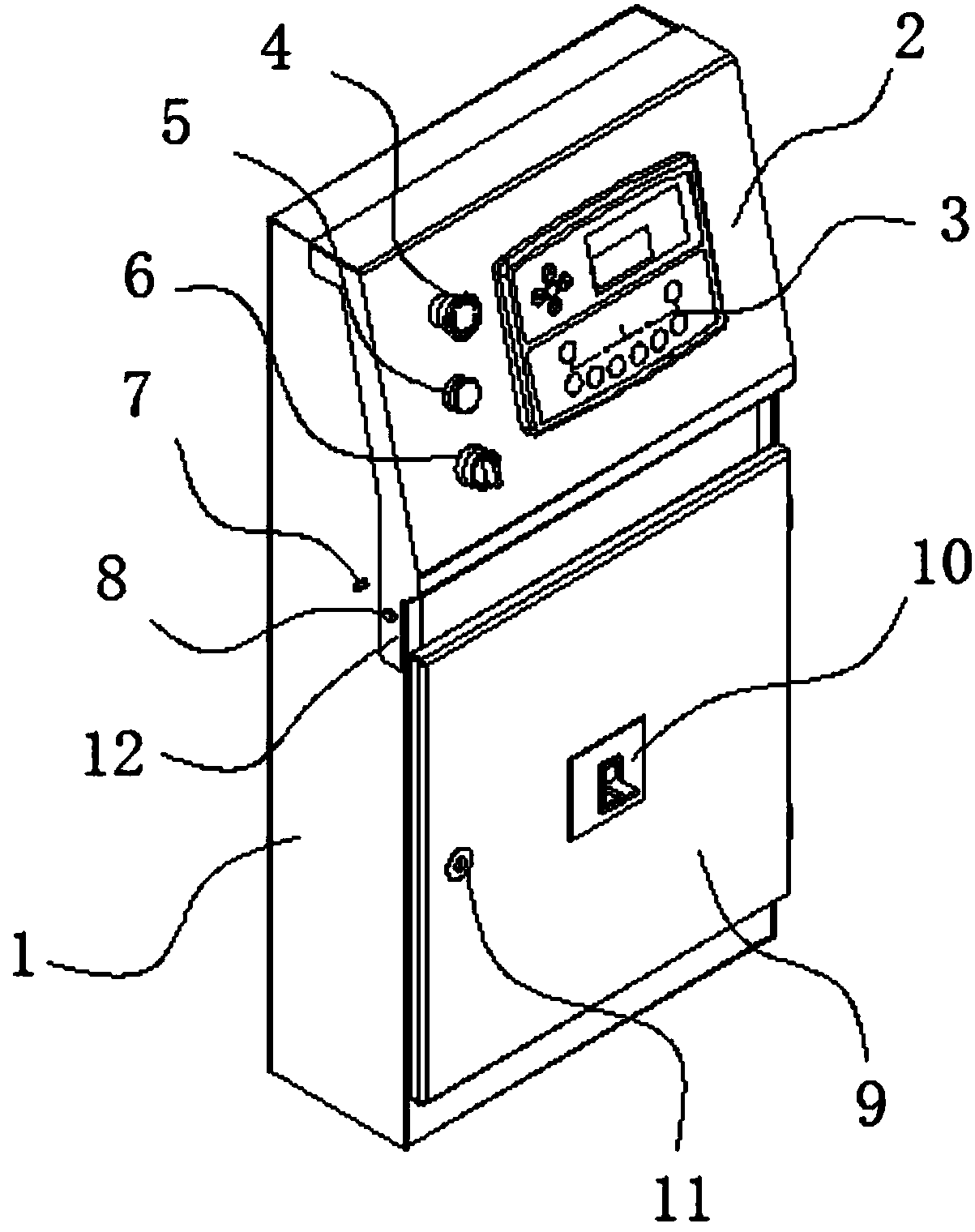

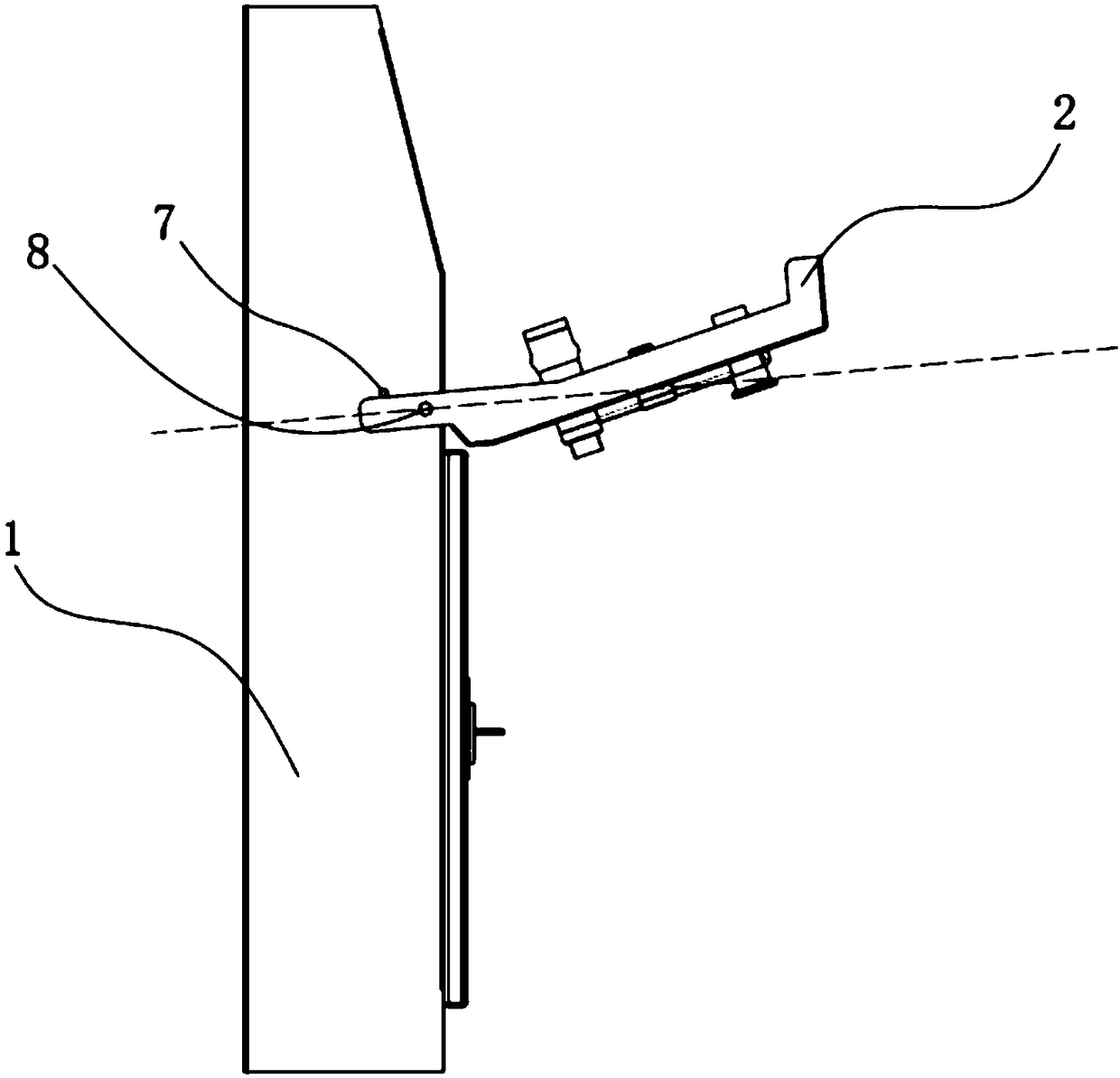

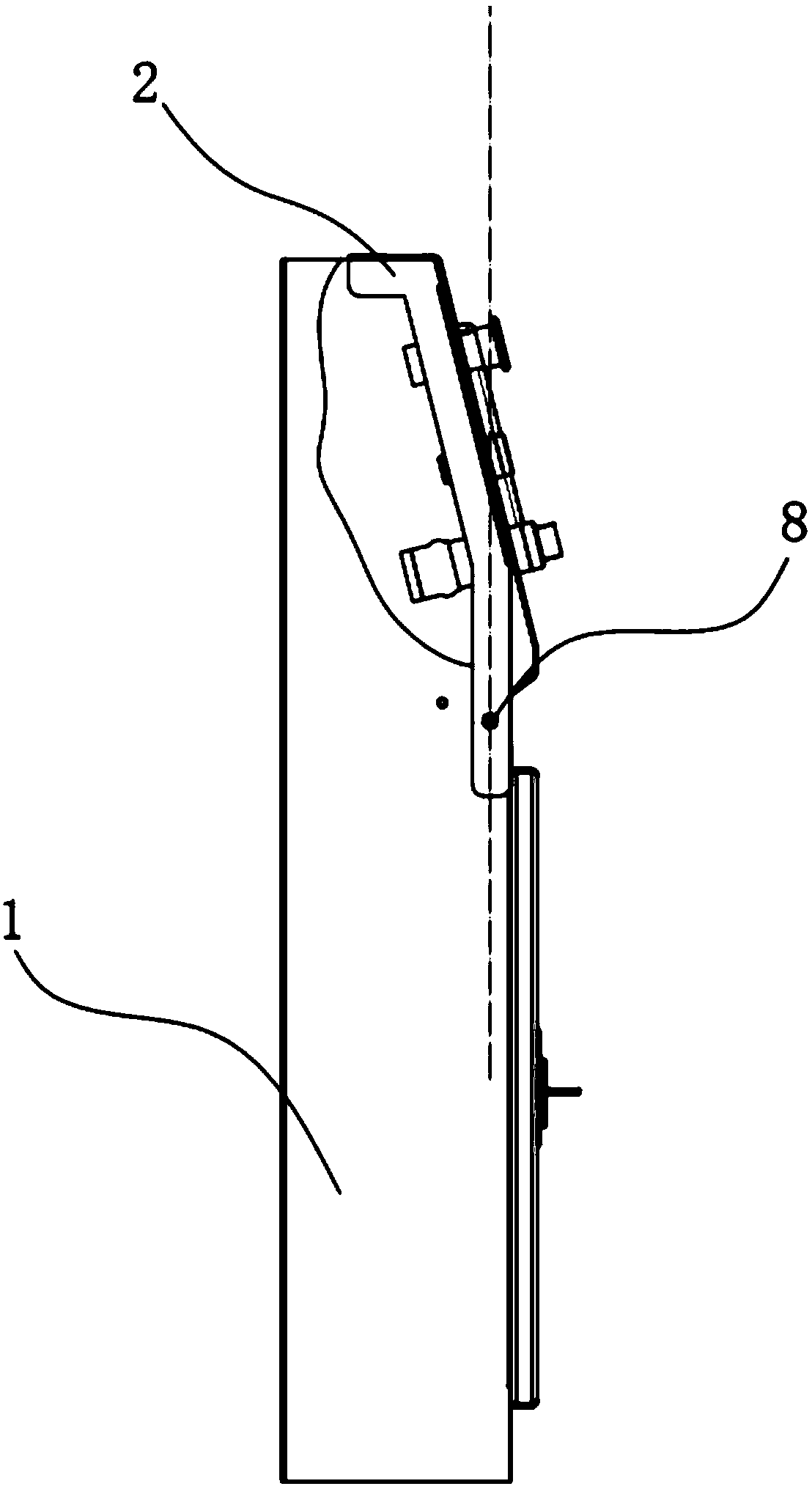

Generator set control box connecting mechanism

PendingCN109347380AReduce points of failureReduce Design ErrorsElectric generator controlPower switchingComputer module

The invention relates to the technical field of an opening and closing mode of an open frame type generator set control box panel, in particular to a generator set control box connecting mechanism. The generator set control box connecting mechanism comprises a control box body, a control box panel, a generator set control module, a sudden stop push button, a buzzer, a power supply switch, a positioning stud, a control box panel fixing shaft, a control box door plate, a circuit breaker and a control box door lock, wherein the upper part of the front surface of the control box body is an inclined surface part; the control box panel is arranged on the inclined surface part; the sudden stop push button, the buzzer and the power supply switch are sequentially arranged at the left side of the surface of the control box panel from top to bottom; and the generator set control module is arranged at the right side of the surface of the control box panel. The generator set control box connectingmechanism has the advantages that the use is convenient; the operation is convenient and fast; and the use of a door lock for fixation when the panel is closed is not needed, so that the work efficiency is greatly improved.

Owner:江苏辛沃动力设备有限公司

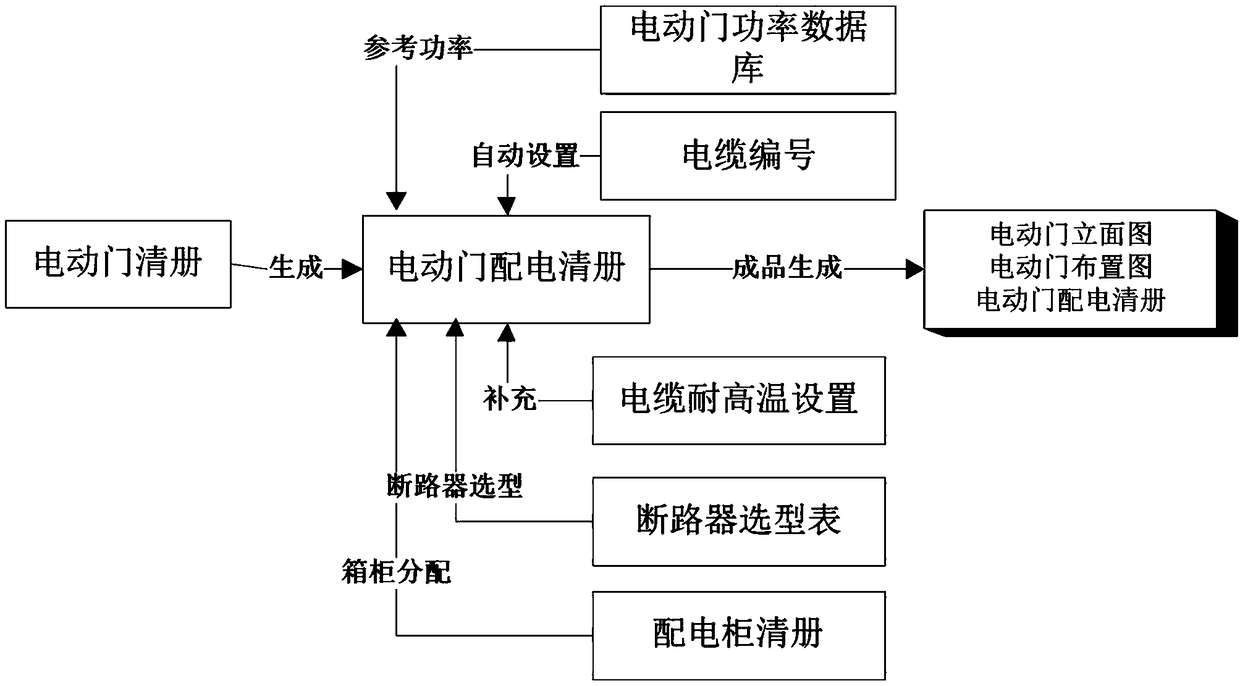

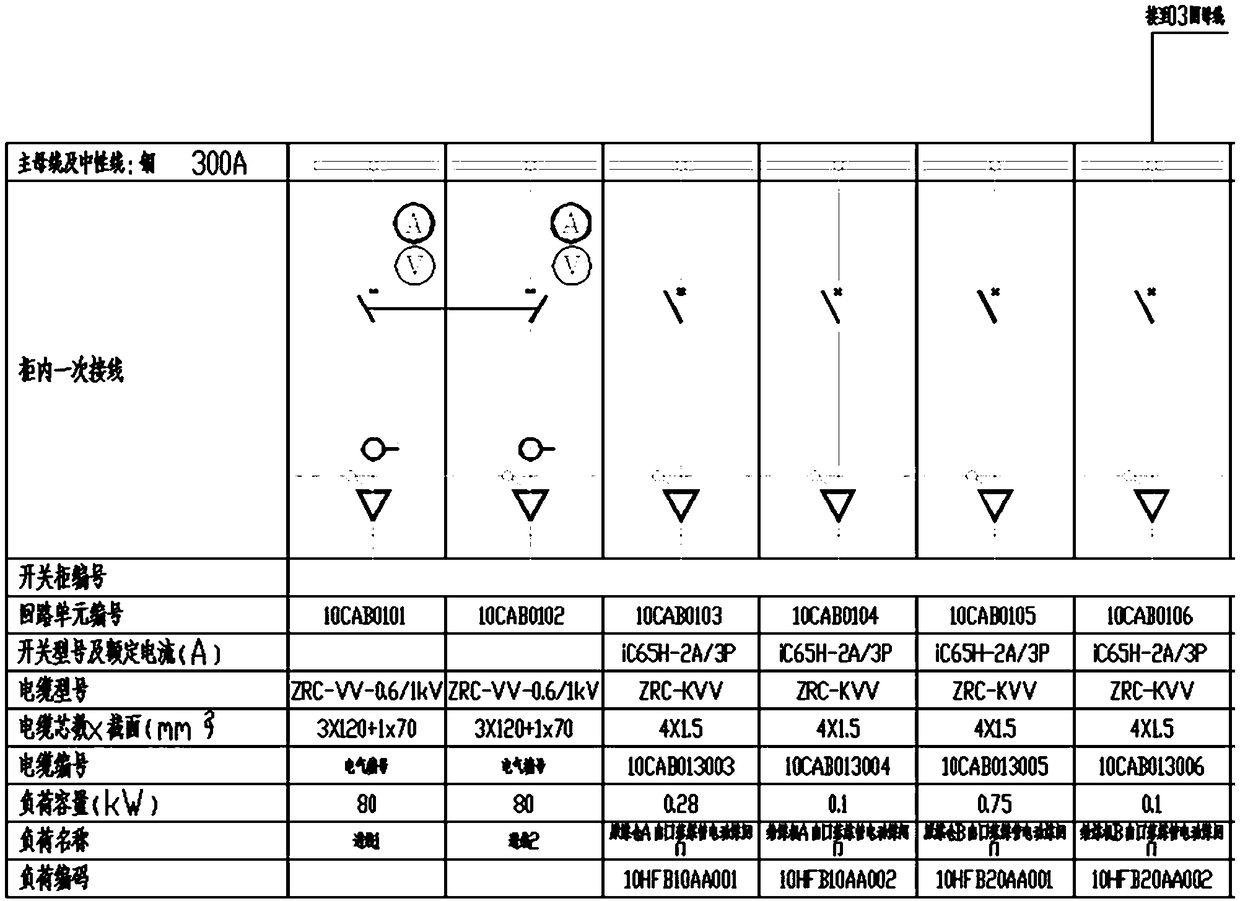

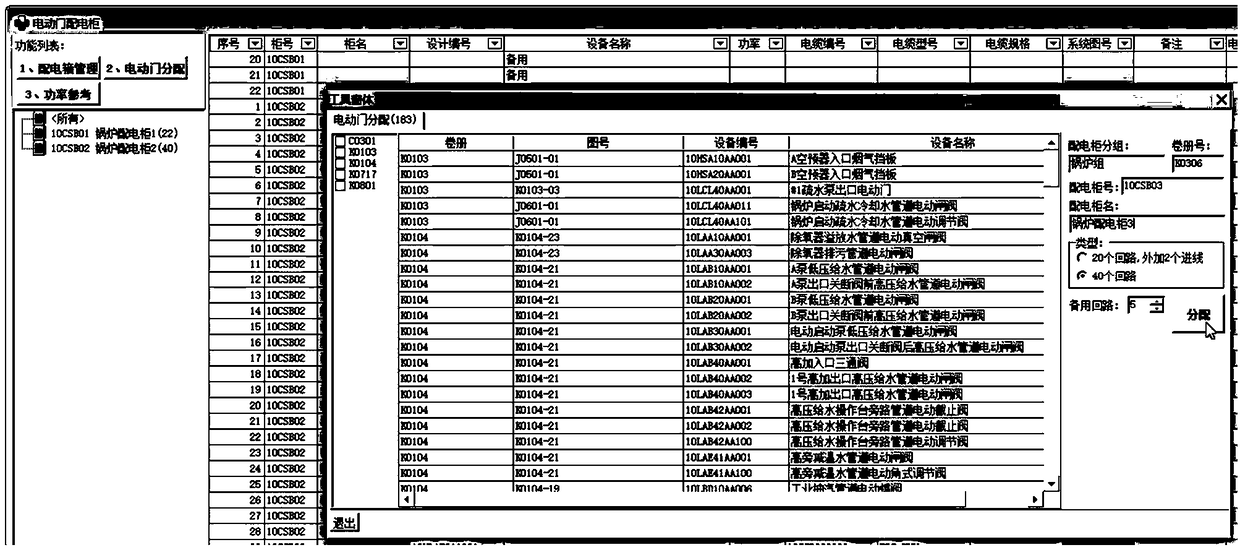

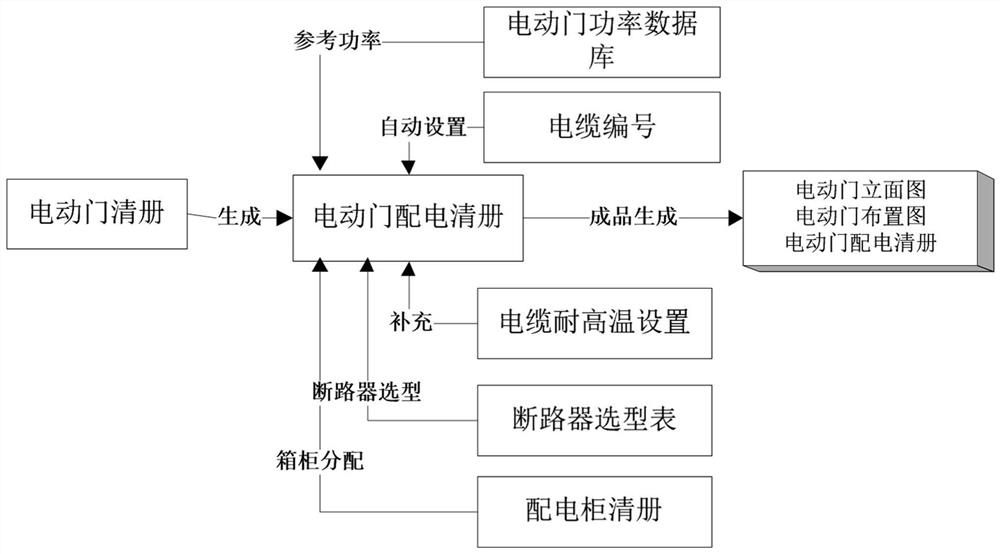

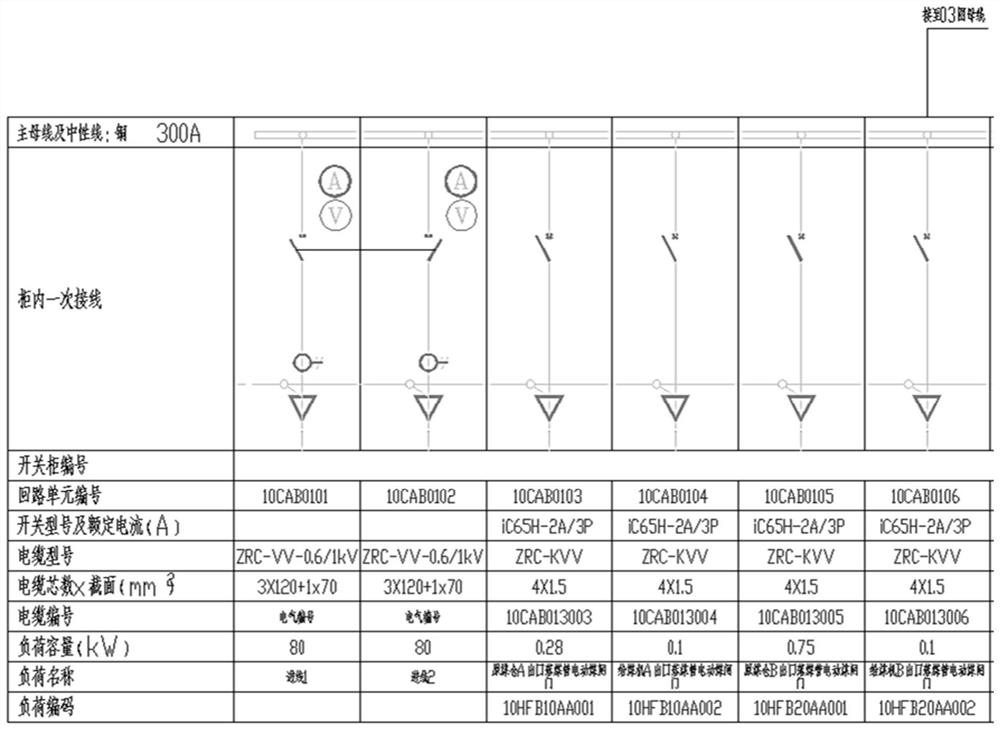

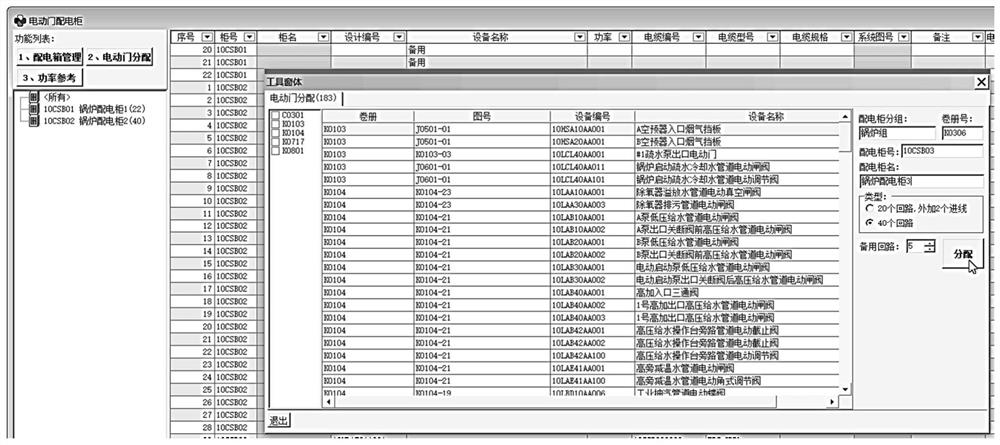

A method for intelligent power distribution and drawing generation of an electric actuator

ActiveCN109165916ARealize automatic selectionRealize automatic generationOffice automationSpecial data processing applicationsDistribution power systemElectric power distribution

A method for intelligent power distribution and drawing generation of an electric actuator comprise that following steps: 1) extracting data of an electric door need to be supplied with power in the project; 2) establishing the power database of the electric door in the existing project; 3) carrying out interactive screening of power database of the electric door; 4) filling that inventory of theelectric door interactively according to the screen content; 5) creating that distribution cabinets in batch according to the power door inventory, and realizing the distribution of the power door bydesignating the numb of spare circuits; 6) selecting that accessory specification according to the power of the electric door and filling in the list of the electric door; 7) according to that electric door inventory, generating the electric door power distribution system diagram and the internal layout diagram. The invention realizes the standardized design of the electric door for the thermal control specialty, the automatic selection of the accessories and the automatic generation of the finished product on the basis of the core data such as the electric door inventory and the power reference table, thereby improving the design efficiency and reducing the design errors.

Owner:NORTHWEST ELECTRIC POWER DESIGN INST OF CHINA POWER ENG CONSULTING GROUP

A method for intelligent power distribution and drawing generation of an electric actuator

ActiveCN109165916BRealize automatic selectionRealize automatic generationGeometric CADOffice automationThermodynamicsSchematic maps

A method for intelligent power distribution and drawing generation of an electric actuator, comprising the following steps: 1) extracting the electric door data that needs power supply in this project; 2) establishing the electric door power database of the existing project; 3) interacting with the electric door power database 4) Interactively fill in the electric door list according to the screening content; 5) Create power distribution cabinets in batches according to the electric door list, and realize the distribution of electric doors by specifying the number of spare circuits; 6) Select the accessories specifications according to the electric door power and Fill in the electric door inventory; 7) Generate the finished product, electric door power distribution system diagram and internal layout diagram according to the electric door inventory. Based on the core data such as electric door inventory and power reference table, the invention realizes the standardized design of electric doors specialized in thermal control, automatic selection of accessories and automatic generation of finished products, improves design efficiency and reduces design errors.

Owner:NORTHWEST ELECTRIC POWER DESIGN INST OF CHINA POWER ENG CONSULTING GROUP

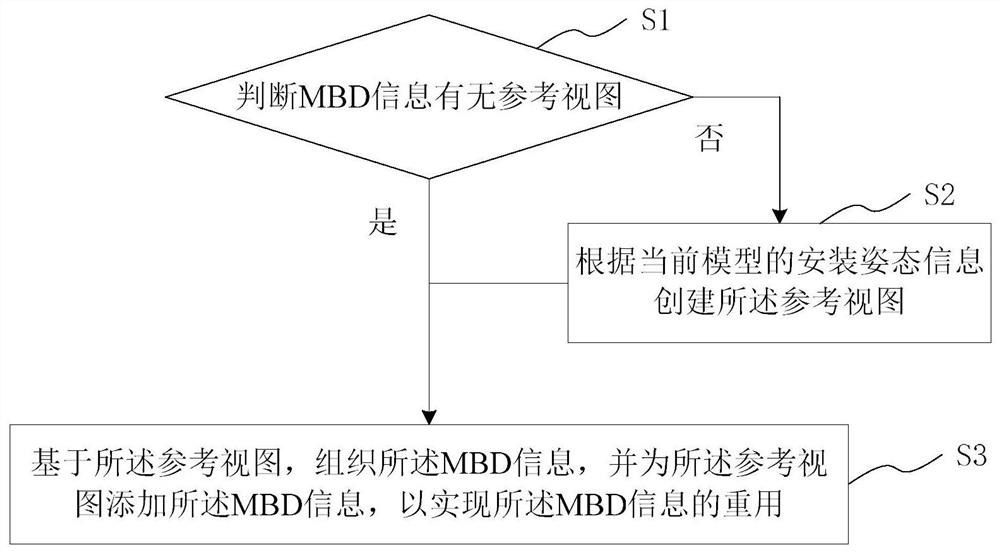

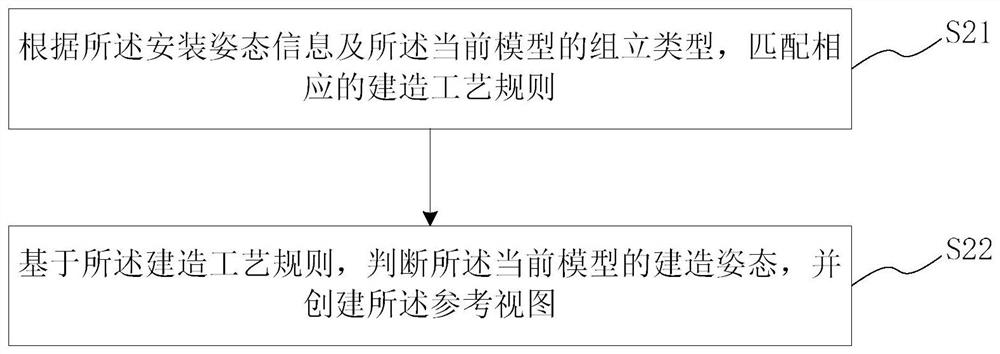

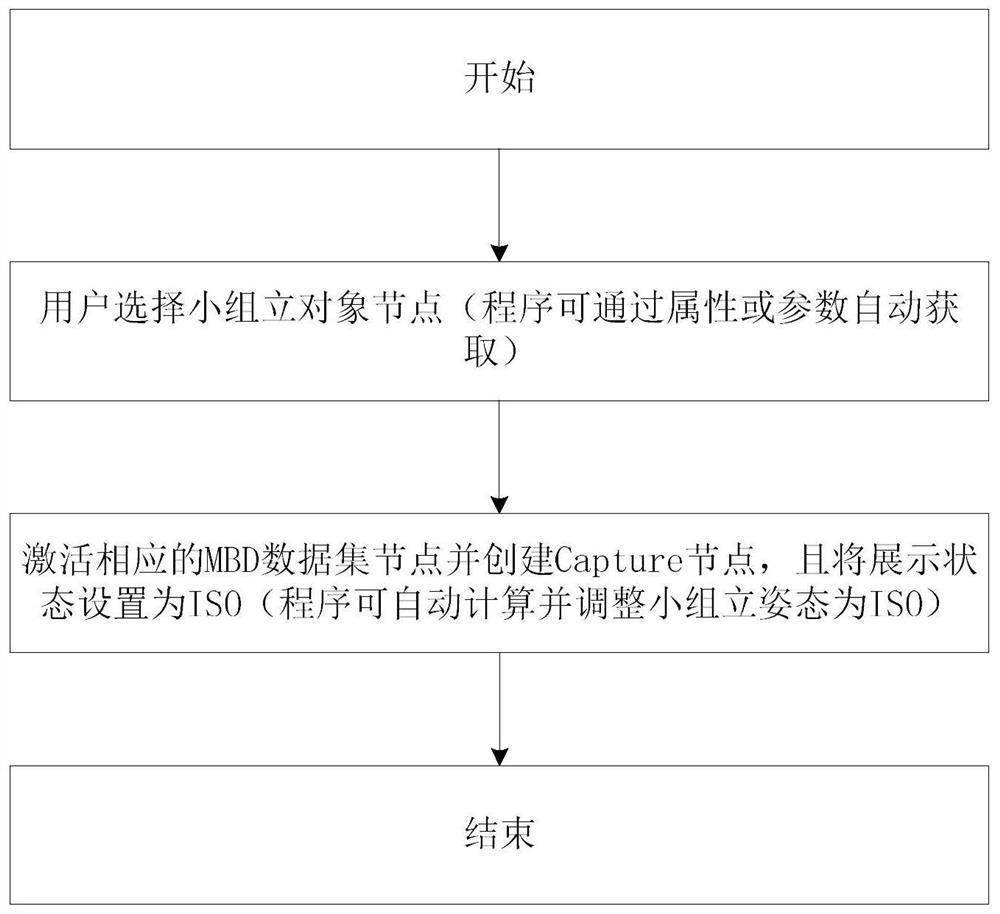

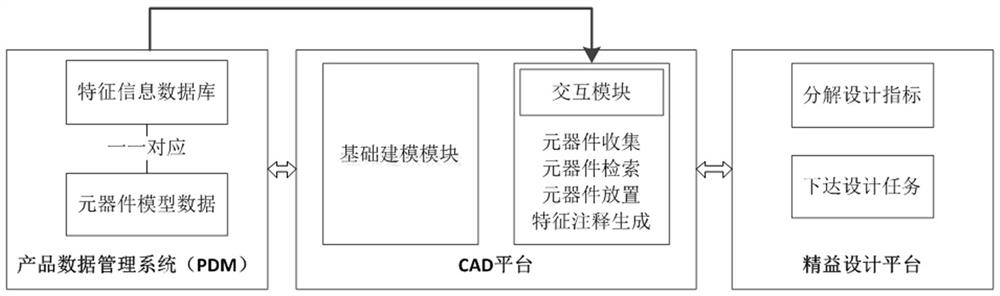

Ship MBD information reuse method and system, medium and terminal

ActiveCN112861267AShorten the design cycleEnsure consistencyGeometric CADDesign optimisation/simulationAlgorithmData source

The invention provides a ship MBD information reuse method and system, a medium and a terminal. The method comprises the following steps: judging whether MBD information has a reference view or not; when the MBD information does not have reference view, creating a reference view according to the installation attitude information of the current model; organizing MBD information based on the reference view, and adding the MBD information to the reference view to achieve reuse of the MBD information, wherein the MBD information comprises three-dimensional marking information of the current model, three-dimensional model information of the current model, construction attitude information of the current model and installation sequence information of the current model; the MBD information reusing method meeting the ship development requirement is researched by combing the construction process rules in the ship professional construction process, so that the design delivery efficiency is improved, and the ship design period is shortened; meanwhile, MBD information reuse is based on a unified data source, design errors can be reduced, information consistency is ensured, and design quality is improved.

Owner:JIANGNAN SHIPYARD GRP CO LTD

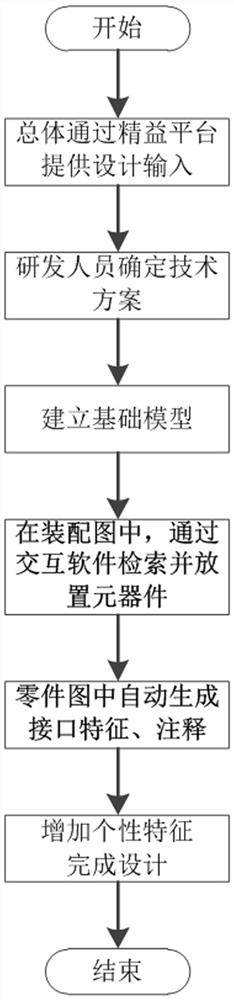

Rapid layout method for radar electronic equipment structure

PendingCN114239182ARealize managementReduce layout timeGeometric CADSpecial data processing applicationsRadarModularity

A radar electronic equipment structure is an important component of a radar, and the structural design period greatly affects the overall development period of the radar. In a radar electronic equipment structure, many same equipment is arranged in a combined and modularized manner, for example, different numbers of cabinets and display and control consoles are arranged in a square cabin. At present, the rapid layout aspect of the radar electronic equipment structure is not explored in China, and a rapid layout method from a scheme to a detailed design is not formed. The invention provides a rapid structure layout method for a radar electronic equipment structure, information widely existing in technical documents originally is collected and integrated through a digital means, and management of component interface data can be realized by combining an interaction module secondarily developed on a three-dimensional CAD platform. And interface features and size annotations are directly generated while the components are dragged and placed, so that the arrangement time of a radar electronic equipment structure design scheme is shortened by 80%, the overall structure research and development efficiency is improved by 60%, the model normalization and reliability are improved, design errors are reduced, and the method has great significance for improving the product quality.

Owner:CHINA ELECTRONICS TECH GRP CORP NO 14 RES INST

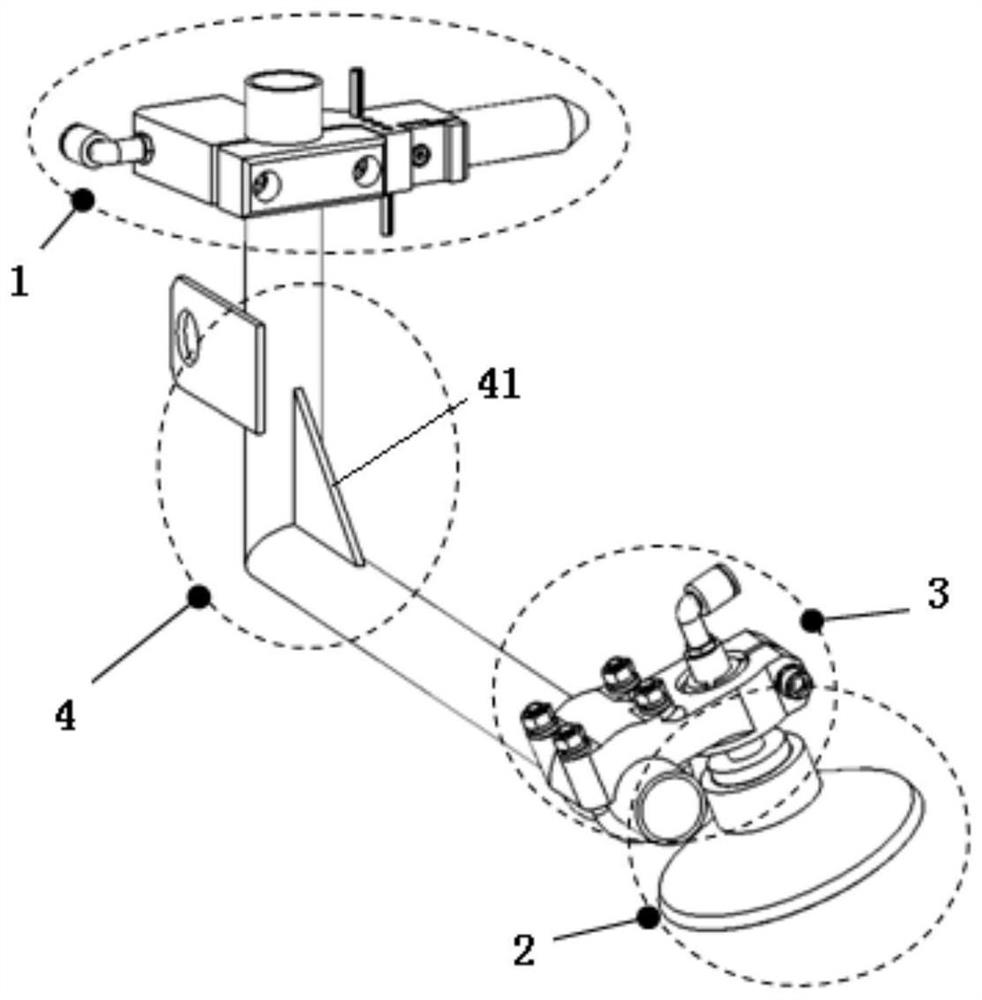

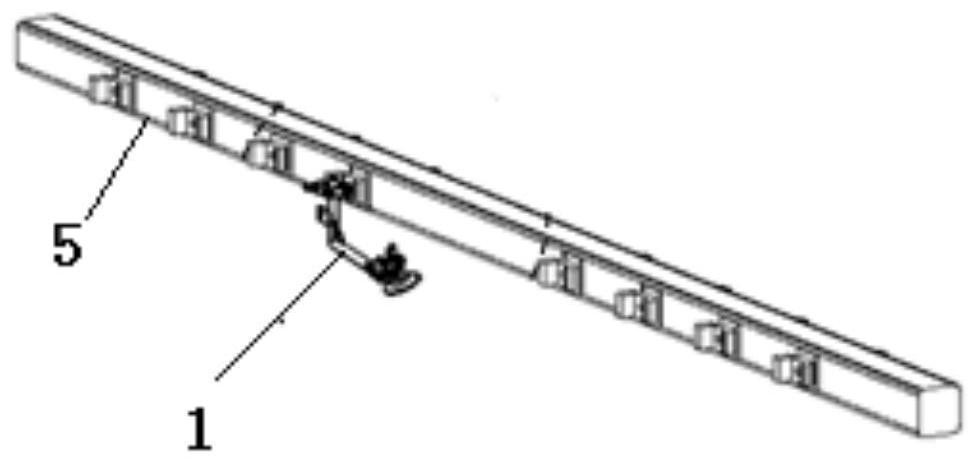

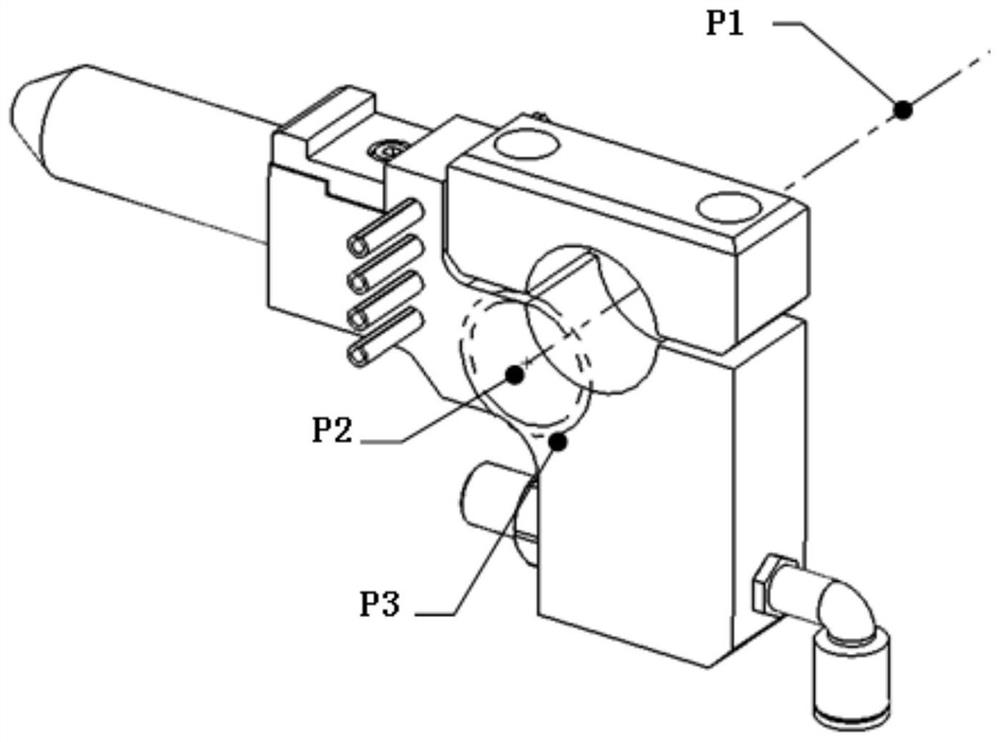

Tooling design method

PendingCN113849927ASimplify computational problemsRapid Intelligent Assembly DesignGeometric CADDesign optimisation/simulationDesign standardPipe

The invention relates to a tooling design method. The method comprises the following steps: S1, assembling a suction cup assembly and a ball shaft assembly; S2, assembling a cross beam assembly and a support assembly; and S3, designing a steel pipe assembly. The ball shaft assembly assembled in step S1 and the support assembly assembled in step S2 are selected, parameters needed by the steel pipe assembly are obtained, the variable-parameter steel pipe assembly is assembled into the ball shaft assembly and the support assembly, and the parameters of the steel pipe assembly are updated. Compared with an existing method, the tooling design method has the advantages that the time is shortened by about 3 / 4, repeated labor is reduced, a tooling can be repeatedly used, the design period of the tooling is greatly shortened, the design error of the tooling is reduced, the design standardization of the tooling is improved, and the design and manufacturing cost of the tooling is reduced.

Owner:东风模具冲压技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com