Fully parametric drawing mould design method

A drawing die and design method technology, applied in computing, electrical digital data processing, special data processing applications, etc., can solve the problems of long design cycle, low degree of standardization, limited and so on, to reduce duplication of labor, improve standardization, reduce effect of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

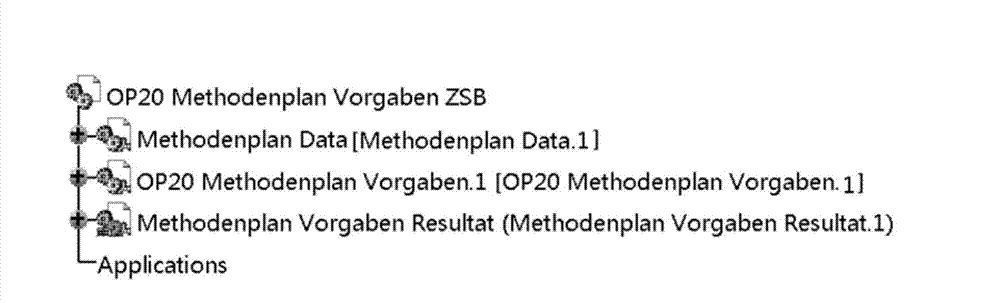

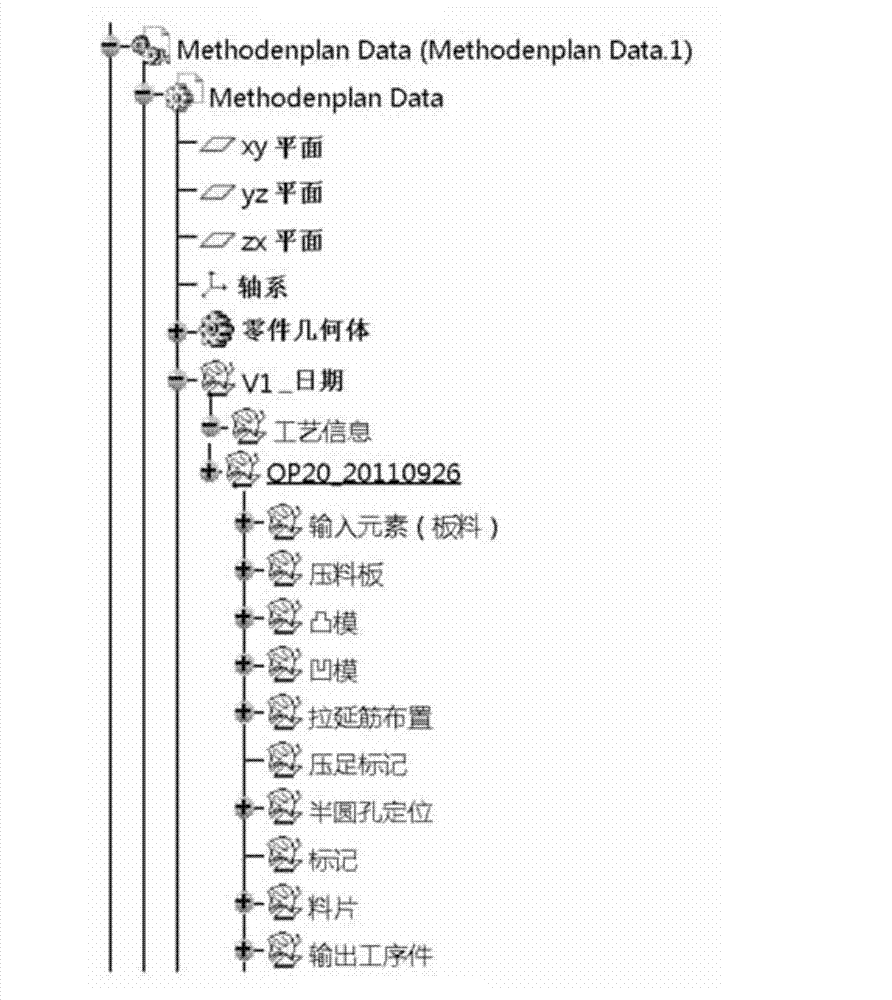

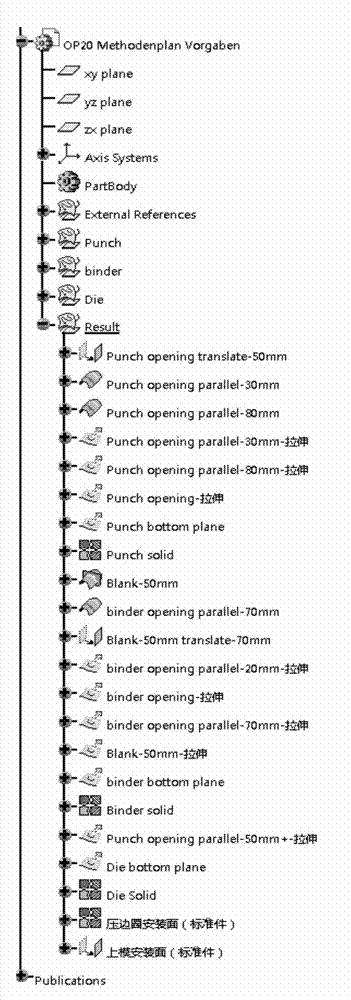

[0028] figure 1 The flow chart of a preferred embodiment of the full parameterized drawing die design method of the present invention is shown. See figure 1 , the following is a detailed description of each implementation step of the fully parametric drawing die design method of this embodiment.

[0029] The fully parametric drawing die design in this embodiment mainly includes the stamping process pre-processing part and the die structure design part. In the pre-processing part of the stamping process, the process data is mainly processed, and the elements of the mold structure design are directly obtained by combining the mold design standards. The process data includes points, lines, and surfaces. The directly obtained elements of the mold structure design include : profile, wireframe, this part is the core of stamping process parameterization. I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com