Motion Simulation Method of Heating Furnace Blank

A motion simulation, heating furnace technology, applied in design optimization/simulation, image data processing, special data processing applications, etc., can solve the problems of long cycle, high cost, limited environment, etc., to achieve short cycle, low cost, operation achieve simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

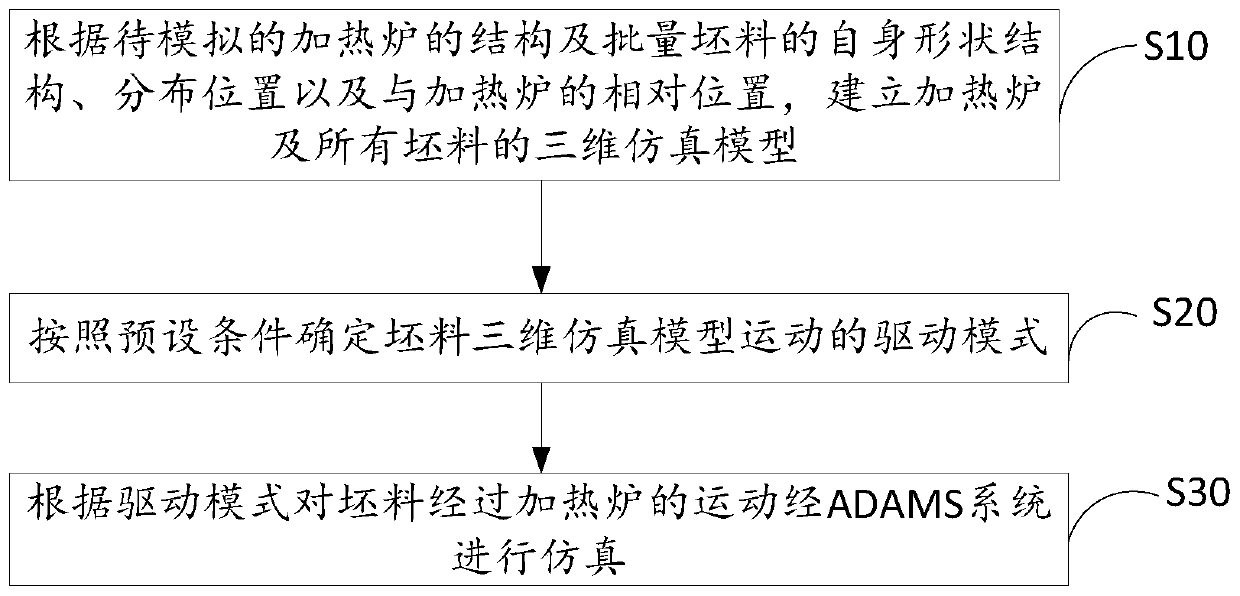

[0038] Such as figure 1 As shown, the present invention provides a method for simulating motion of a heating furnace billet, comprising:

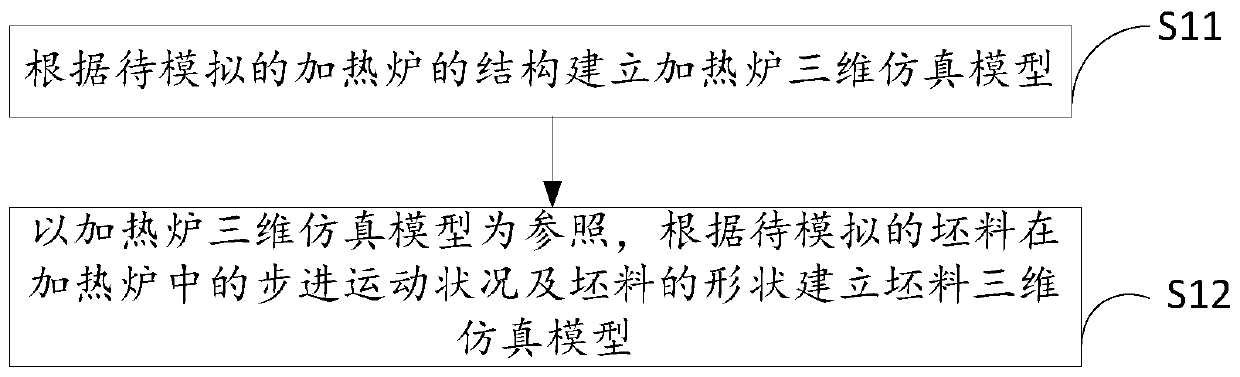

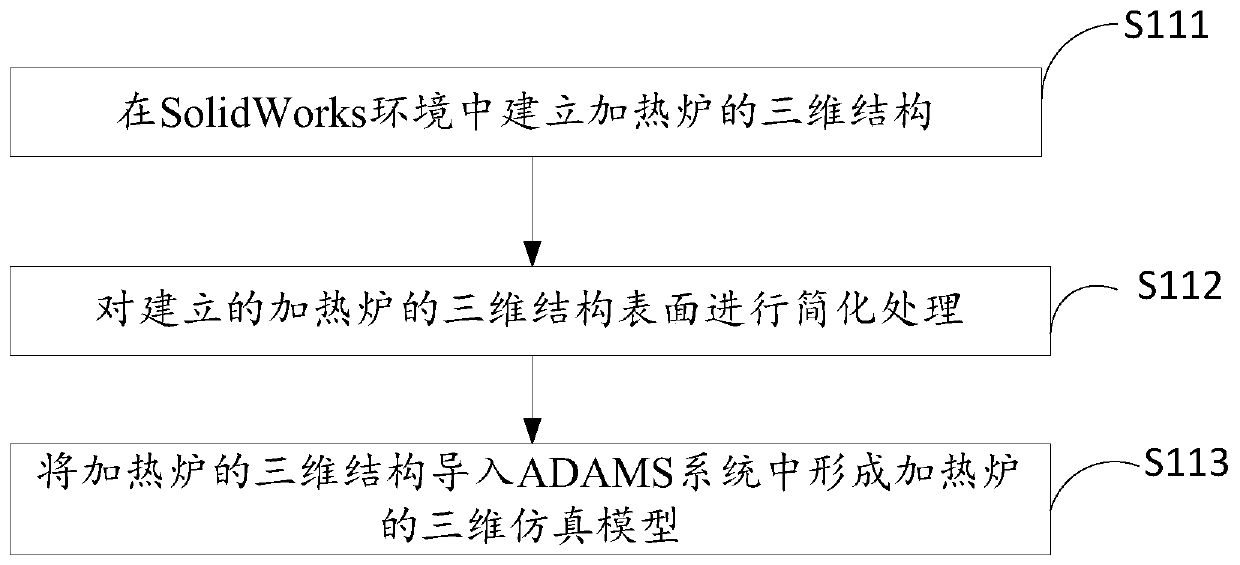

[0039] Step S10, according to the structure of the heating furnace to be simulated and the shape structure, distribution position and relative position to the heating furnace of the batch of blanks, establish a three-dimensional simulation model of the heating furnace and all the blanks;

[0040] In one embodiment of the present invention, 64 steel billets are used as a batch of billets to be heated through a heating furnace, and the 64 steel billets are arranged in parallel with the longitudinal axis Y direction on the vertical plane formed by the X and Y axes; A from right to left 1 、A 2 、A 3 ...A i ...A 64 ;The length direction of the heating furnace is set along the vertical axis Z direction, in the initial position, the first steel billet A 1 The location close to the feed inlet of the heating furnace, so that the modeling of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com