Electrical assembling method for modulator power supply cabinet

A power supply cabinet and modulator technology, which is applied in the fields of instruments, electrical digital data processing, special data processing applications, etc., can solve the problem that the color and length of wires cannot be determined, the type of connector pins and the length of wires cannot be accurately determined, and the drawing efficiency is low. and other problems, to achieve the effect of improving rapid research and development capabilities, facilitating assembly line operations, and improving speed and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

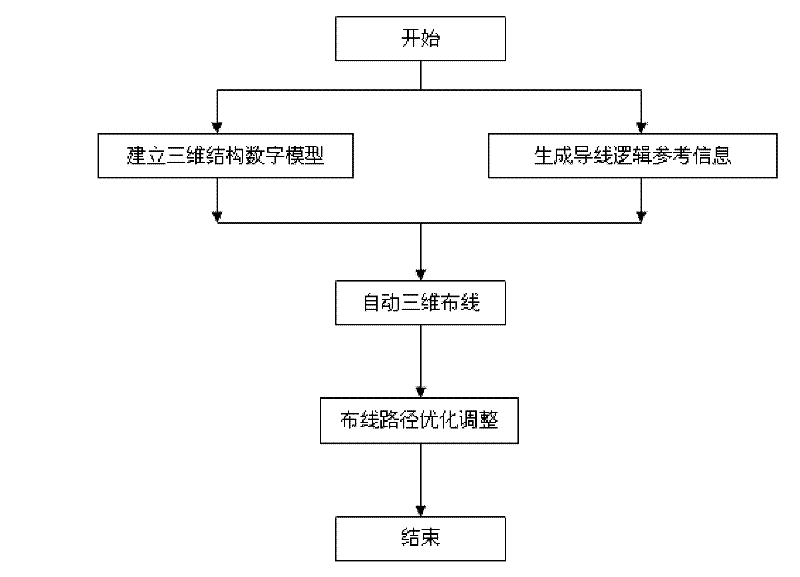

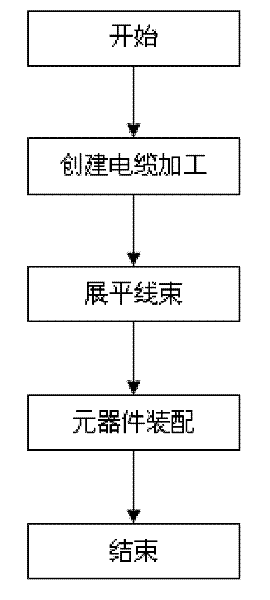

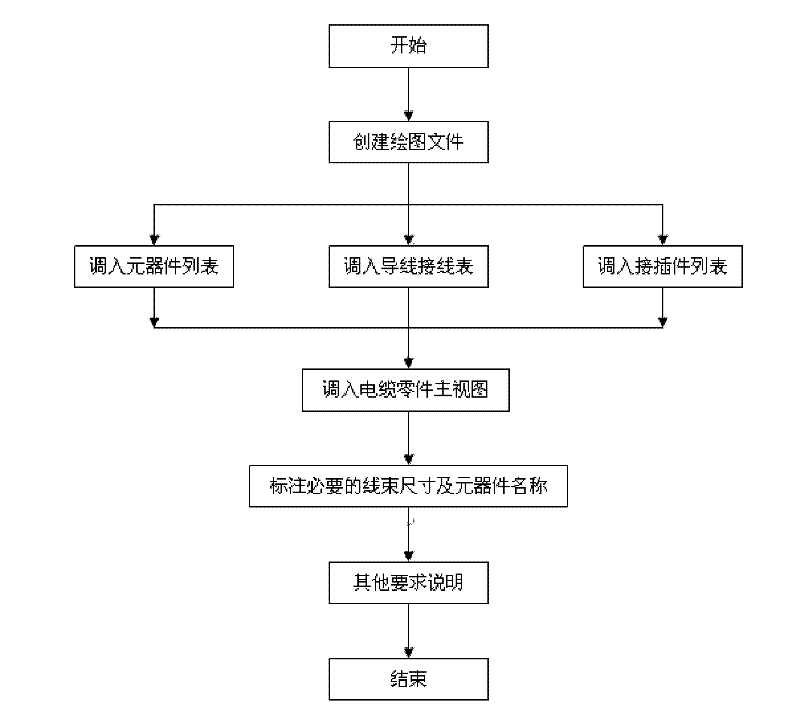

[0020] The present invention uses computer software as an auxiliary tool, through the cable wiring relationship established on the basis of the three-dimensional digital structure model of the wiring space, the electrical connection between the components is performed, and the automatic three-dimensional wiring is completed, and then the wiring harness completed by wiring is flattened and Component assembly, generate wire harness flattening files, create wire harness flattening diagrams, and convert them into CAD wiring diagrams.

[0021] The present invention uses PRO / E software to form a three-dimensional wiring operation platform to realize the design of three-dimensional wiring and generate wiring diagrams. The PRO / E software is a mainstream and comprehensive computer-aided three-dimensional design and manufacturing software developed by the American PTC company in the world. , the software has powerful 3D simulation capabilities, good scalability, flexible application attr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com