Tooling design method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

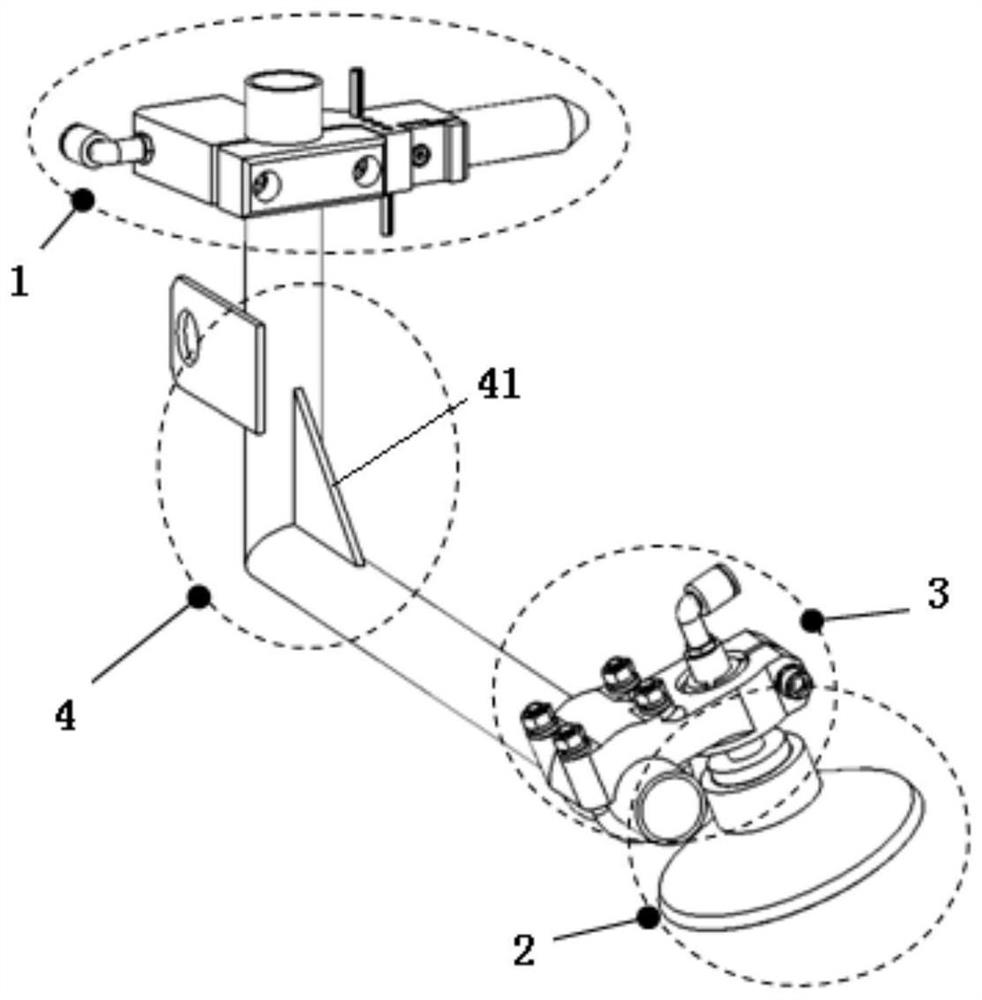

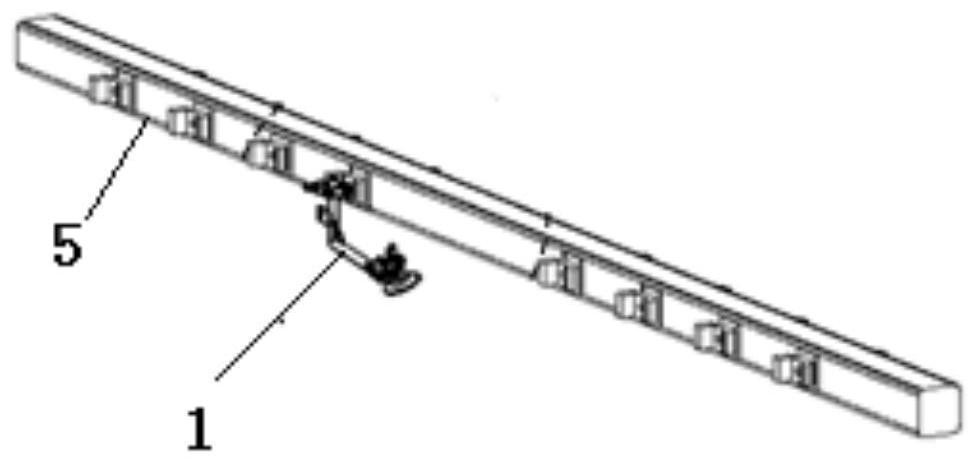

[0047] Such as figure 1 As shown, a complete set of end effector is composed of dozens of parts. According to the function and use of the parts, the end effector is divided into four major parts: bracket assembly 1, suction cup assembly 2, ball shaft assembly 3 and steel pipe Composite 4.

[0048] Such as Figure 2-7 As shown, a method for designing an end picker of the present invention includes the following steps:

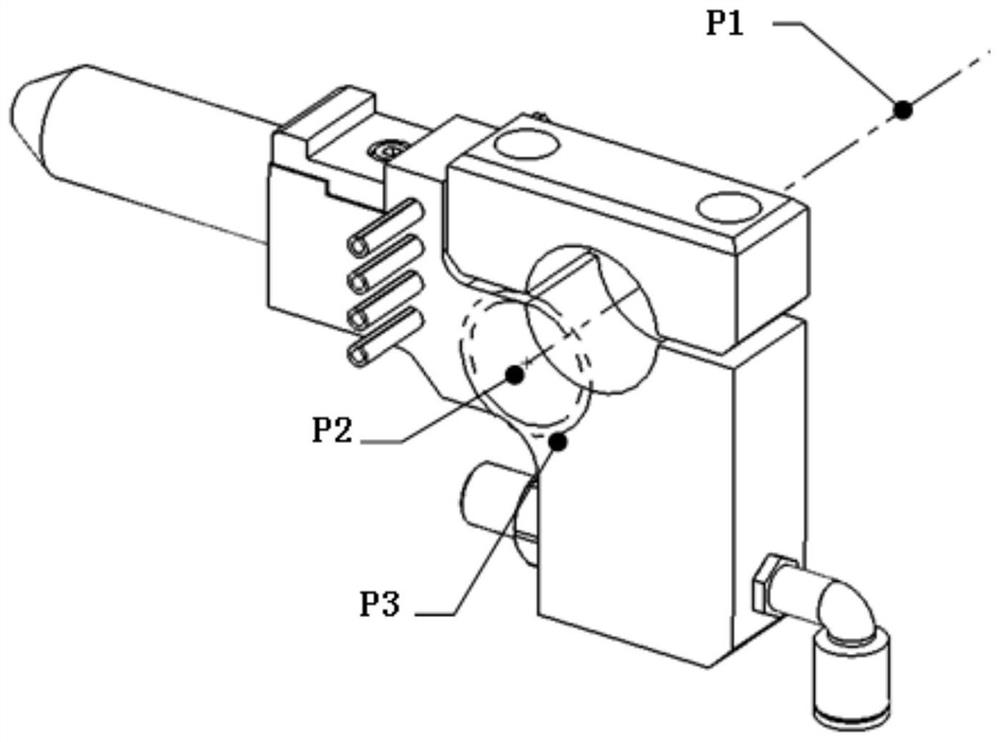

[0049] S1, assembly of suction cup assembly 2 and ball shaft assembly 3:

[0050] According to the process part data with the position and size of the suction cup provided by the stamping process, select the arc line of the suction cup and the surface where the arc line is located, extract the center point of the arc and the normal vector of the surface passing through the center point, and assemble the suction cup assembly 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com