Method for automatically inserting logic supports and hangers in pipeline design

A technology of pipeline design and automatic insertion, applied in computer-aided design, design optimization/simulation, calculation, etc., can solve the overall problems of reducing work efficiency, time-consuming process of positioning logical support and hanger, and unfavorable to the design level of pipeline support and hanger. Improve and other issues to achieve the effect of reducing design errors and improving design efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

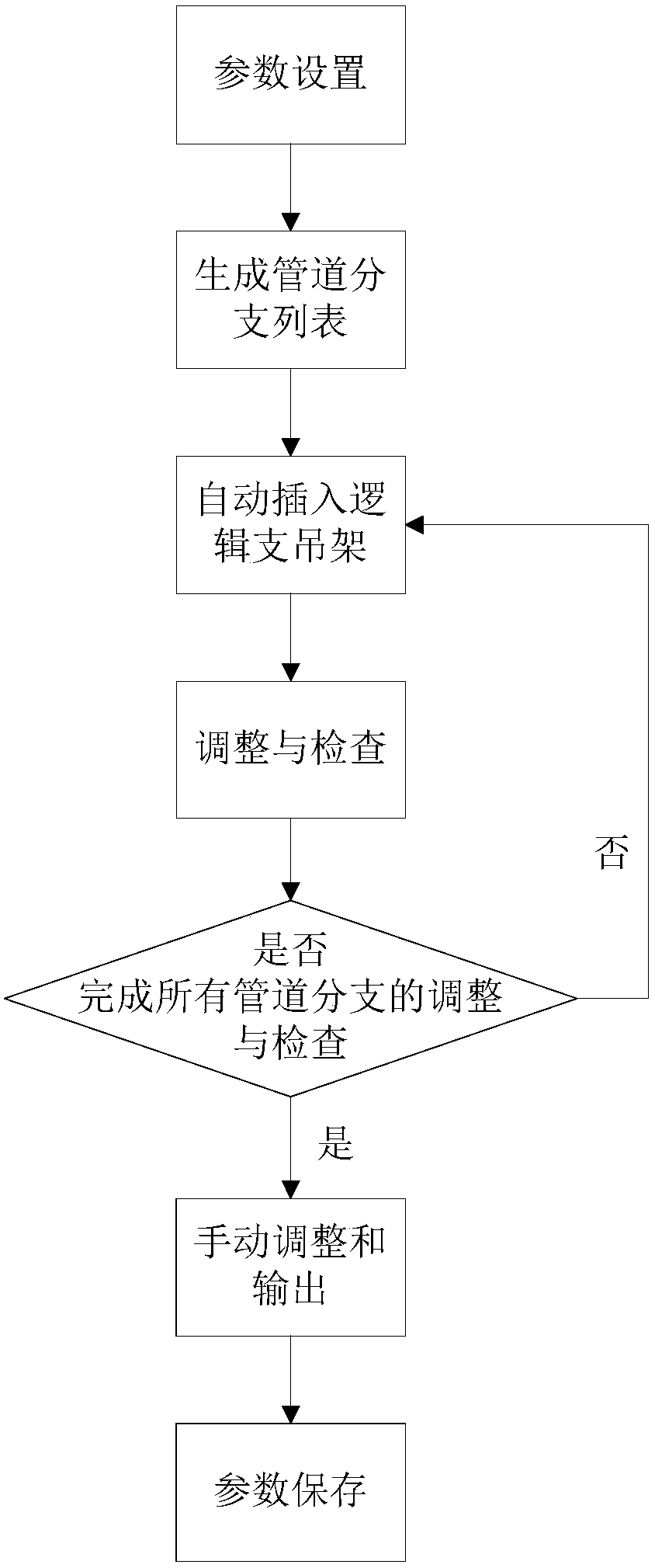

[0026] Such as figure 1 The method for automatically inserting the logic support and hanger in the pipeline design of the present invention shown includes:

[0027] A. Parameter setting: read the current optimal parameter scheme and alternative scheme from the parameter library, the parameters include the adjustment coefficient K of the support and hanger spacing and the coefficient K1~K7 for checking whether the support and hanger setting is reasonable, and the support and hanger spacing The initial value of the adjustment coefficient K is 0.9. The parameters specifically include:

[0028] L0: Maximum spacing of horizontal straight pipe supports and hangers:

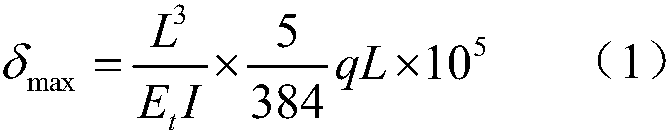

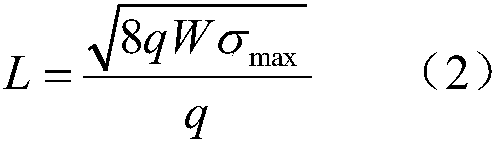

[0029] According to the formula for the maximum horizontal distance between supports and hangers of straight pipe sections without concentrated load in "DL / T5054-2016 Code for Design of Steam and Water Pipelines in Thermal Power Plants", that is, the horizontal straight pipe supports and hangers calculated from formul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com