Quick connector for optical fiber installation

An installation and connector technology, applied in the direction of light guide, optics, instruments, etc., can solve the problems of complicated operation and many carrying tools.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

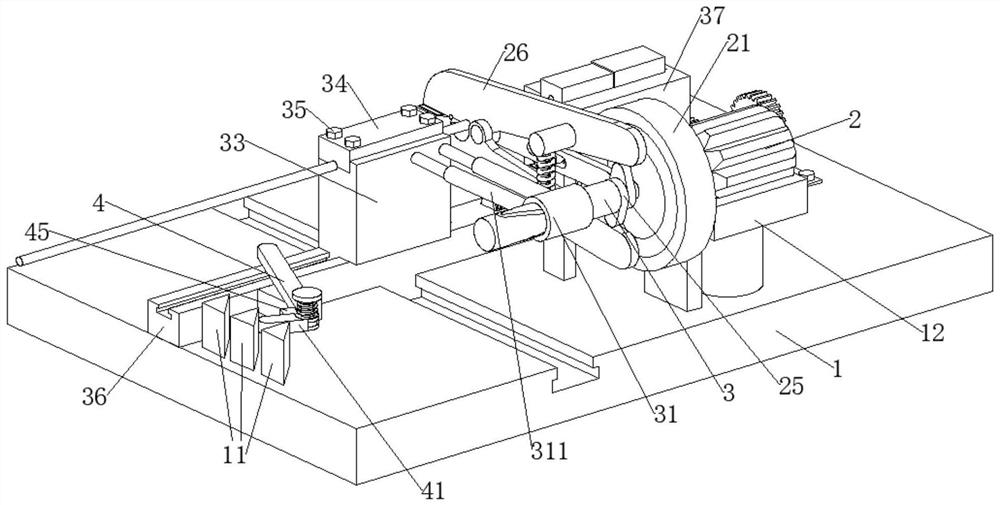

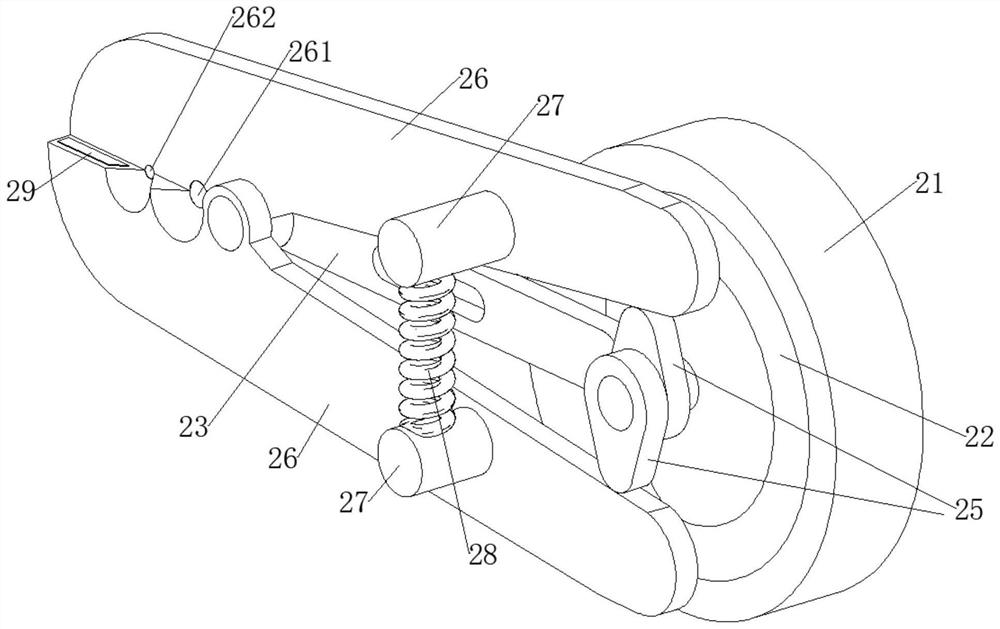

[0028] The present invention provides a technical solution: a quick connector for optical fiber installation, comprising a mounting plate 1, a base 12 is fixedly connected to the mounting plate 1, a motor 2 is fixedly connected to the base 12, and an output end of the motor 2 is fixedly connected There is a disc 21, two symmetrically arranged expansion cams 25 are fixedly connected to the disc 21, a column 5 is fixedly connected to the mounting plate 1, a horizontal plate 23 is slidably connected to the column 5, and a slider is fixedly connected to the horizontal plate 23. 24. The disc 21 is provided with a chute 22 that cooperates with the slider 24, the horizontal plate 23 is rotatably connected with two clamping plates 26 that cooperate with each other, and the two clamping plates 26 are fixedly connected with mounting posts 27. A tension spring 28 is fixedly connected between the 27, the two expansion cams 25 are alternately abutted against the two clamping plates 26, and ...

Embodiment 2

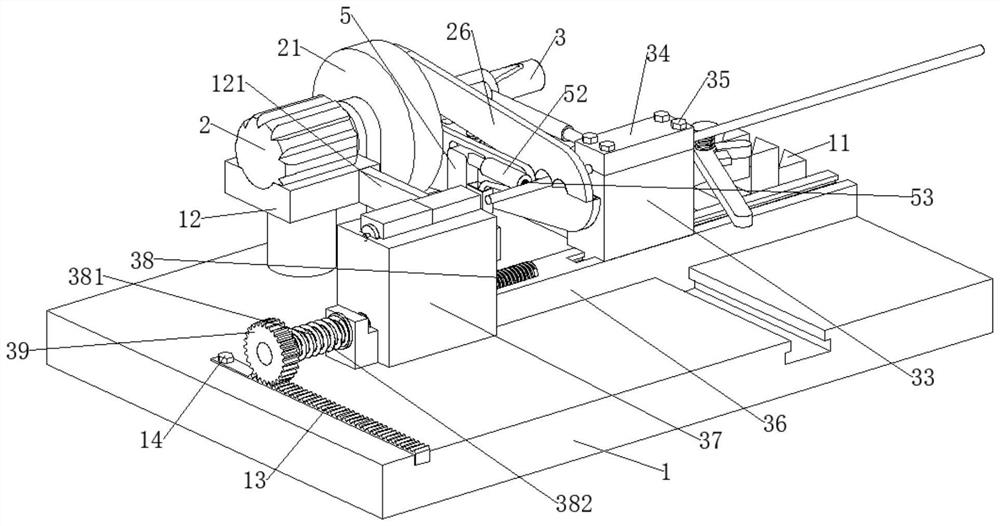

[0031] On the basis of the first embodiment, further, the mounting plate 1 is provided with a fixing mechanism for fixing the optical fiber. The fixing mechanism includes a rectangular bar 36 slidably connected to the mounting plate 1, and a locking block 33 is slidably connected to the rectangular bar 36. , a pressure plate 34 is installed on the locking block 33, a first screw 35 is threadedly connected to the pressure plate 34, a threaded hole is provided on the locking block 33 to cooperate with the first screw 35, and the locking block 33 and the pressure plate 34 are jointly opened with a fiber optic fitting. A cylindrical cam 3 is fixedly connected to the expansion cam 25 , and a cylinder 31 is slidably connected to the cylindrical cam 3 .

[0032] refer to figure 1 , figure 2 , image 3 , Figure 4 and Image 6, when the disk 21 drives the expansion cam 25 to rotate, the cylindrical cam 3 fixedly connected with the expansion cam 25 can rotate synchronously with th...

Embodiment 3

[0036] On the basis of the second embodiment, further, one end of the rectangular bar 36 away from the locking block 33 is slidably connected with a placing block 37 for placing the optical fiber plug, and the placing block 37 is provided with a groove for matching with the optical fiber plug. 36 is rotatably connected with a threaded rod 38, one end of the threaded rod 38 away from the rectangular strip 36 is coaxially and fixedly connected with a cylindrical rod 381, the cylindrical rod 381 is rotatably connected with a gear 39, and the mounting plate 1 is mounted with a tooth meshing with the gear 39. The rack 13, the rack 13 is threadedly connected with a second screw 14, the mounting plate 1 is provided with a threaded hole that cooperates with the second screw 14, the lower surface of the placing block 37 is provided with a threaded groove that cooperates with the threaded rod 38, and the cylindrical rod 381 is sleeved with a second torsion spring 382, the two ends of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com