Device for stripping waste cable

A technology for waste cables and cables, which is applied in the direction of cable installation, cable installation devices, equipment for dismantling/armoring cables, etc., and can solve the problem of unsatisfactory separation between the insulation layer and the cable core, and the clamping and peeling of cables with different diameters. Unsatisfactory effect and other problems, to achieve good peeling effect, avoid damage to the cable core, and good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

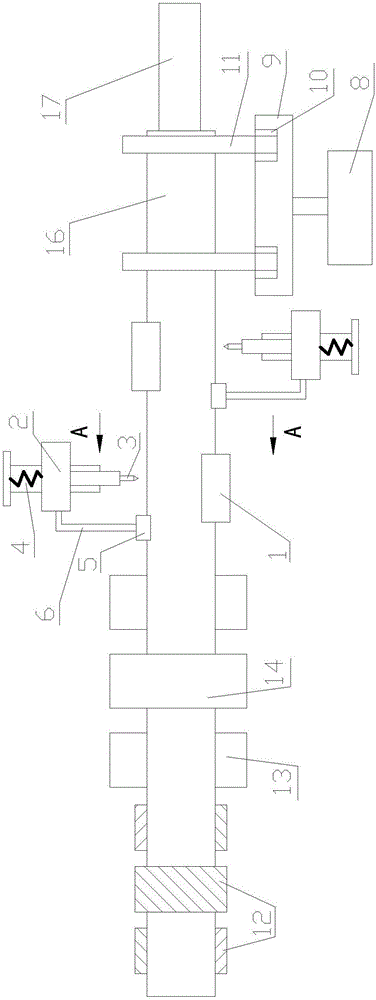

[0031] refer to figure 1 —4:

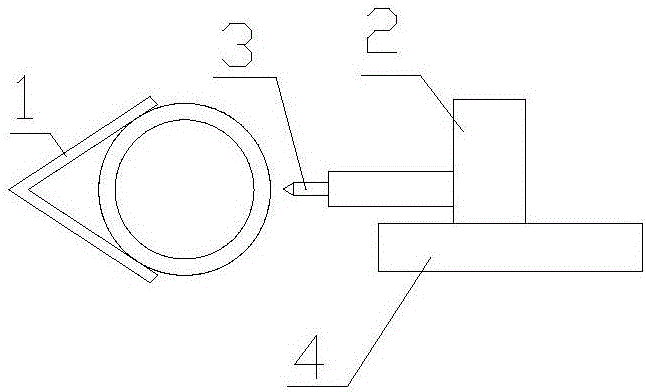

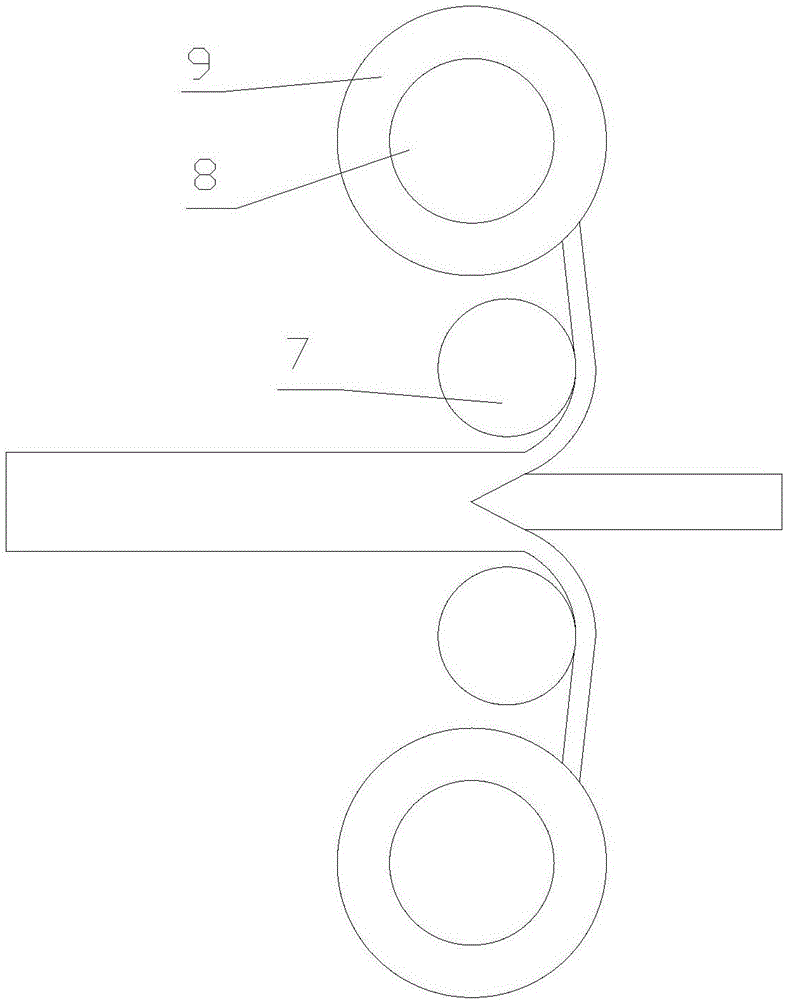

[0032] The present invention proposes a device for stripping waste cables, including a stripping mechanism for destroying the insulation layer on the cable, the stripping mechanism includes N stripping units, the stripping units are distributed along the moving direction of the cable, and the stripping unit includes The "V"-shaped clamping plate 1, cylinder 2, and blade 3 that clamp the cable, the cylinder 2 drives the blade 3 to displace along the radial direction of the cable, and the two clamping arms of the clamping plate 1 are arranged symmetrically with respect to the blade 3, the The blade 3 and the clamping plate 1 are distributed on both sides of the cable.

[0033] Because the clamping plate 1 is a "V" shape, it can clamp cables of different diameters. When clamping cables of different diameters, the axial direction of different cables is displaced along the extension direction of the blade 3. Therefore, the blade 3 can be used to 3. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com