Anti-loose screw with special structure and processing technology of anti-loose screw

A processing technology and screw technology, applied in the direction of screws, bolts, nuts, etc., can solve the problems of loose screws, poor screw connection stability, loose connection objects, etc., to strengthen the stability, realize automatic driving and automatic reset, and increase the contact area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

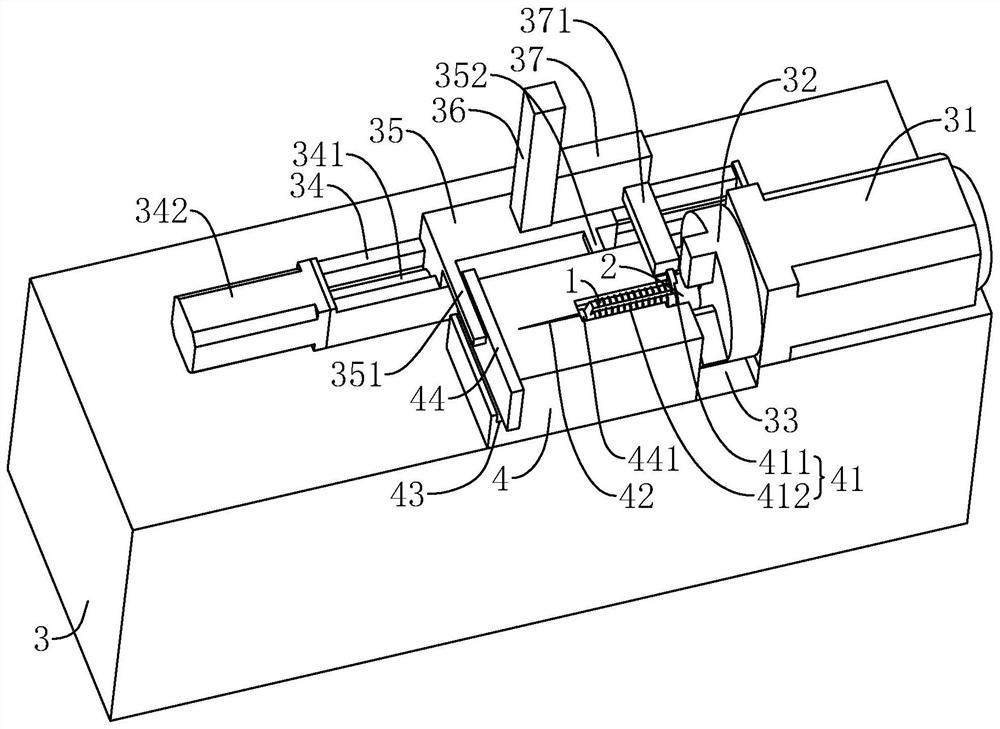

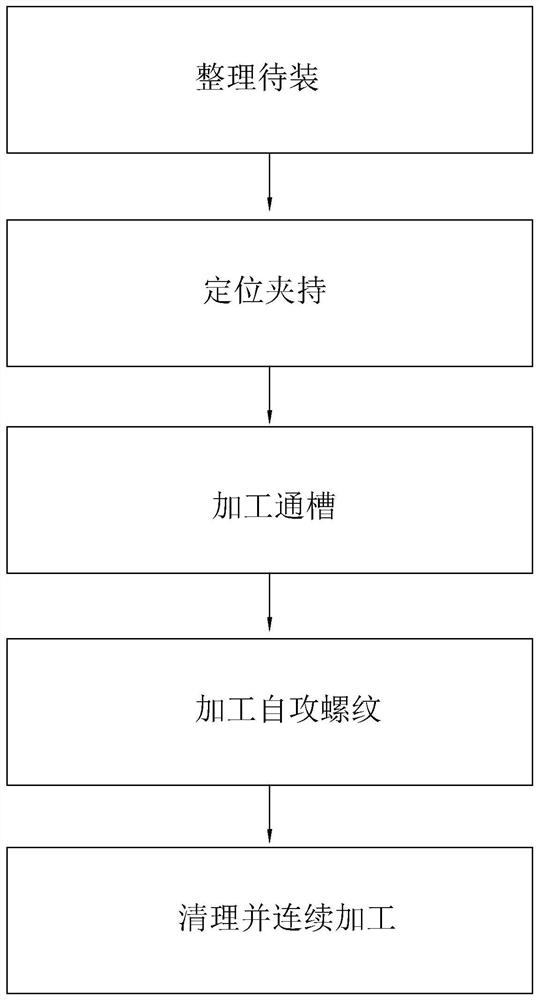

[0040] The following is attached Figure 1-3 The application is described in further detail.

[0041] The embodiment of the present application discloses a special anti-loosening structural screw.

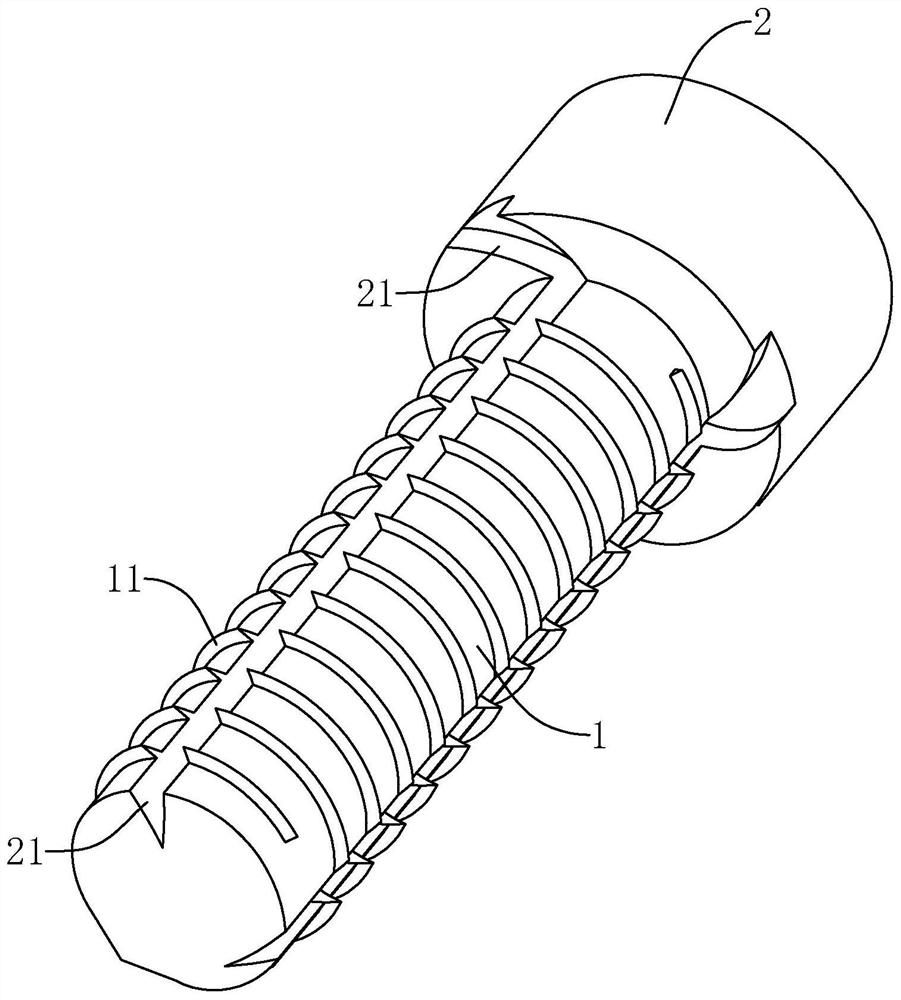

[0042] refer to figure 1 The anti-loosening special structure screw includes an integrally formed screw 1 and a nut 2. The circumferential side wall of the screw 1 is provided with a self-tapping thread 11, and the screw 1 is provided with a plurality of through grooves 21 through the self-tapping thread 11. Three grooves 21 are provided along the length direction of the screw 1, and the end surface of the nut 2 facing the screw 1 is also provided with a through groove 21, the through groove 21 on the nut 2 communicates with the through groove 21 on the screw 1.

[0043] refer to figure 1 , the through groove 21 is arranged obliquely in the direction away from the self-tapping thread 11 screwed in, and the notch of the through groove 21 is tapered along the axial direction close...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com