Test structure artwork forming method and system and test structure forming method

A technology for testing structure and structure pattern, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as low efficiency, and achieve the effect of simplifying testing procedures, simple patterns, and reducing open circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0074] In the design of semiconductor integrated circuits, it is often necessary to form a test structure to verify whether the designed device and the manufacturing process of the device meet the requirements.

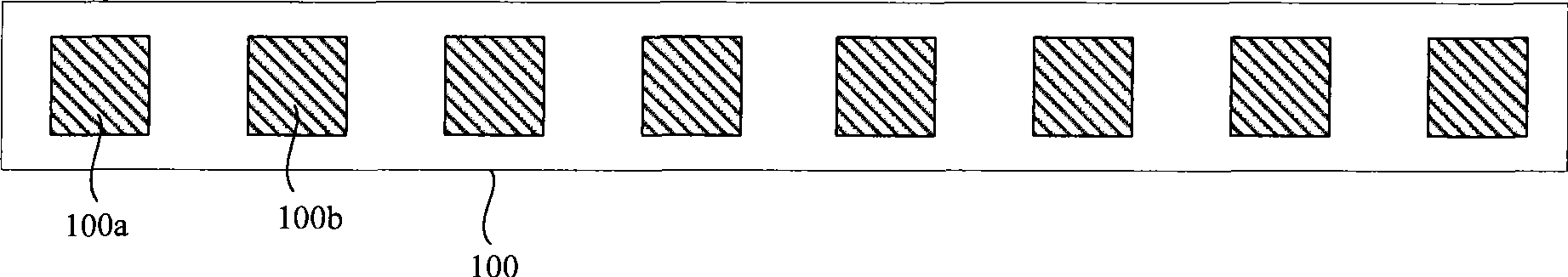

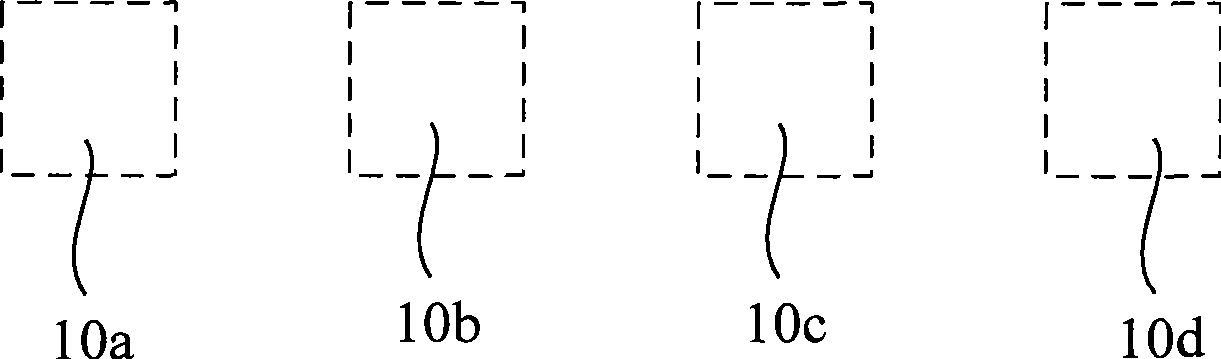

[0075] The present invention provides a method for forming a test structure layout, comprising forming at least two dummy wire pad patterns, and arranging the dummy wire pad patterns according to the layout of the wire pad patterns, and the dummy wire pad patterns The size and spacing are the same as the actual lead pad pattern.

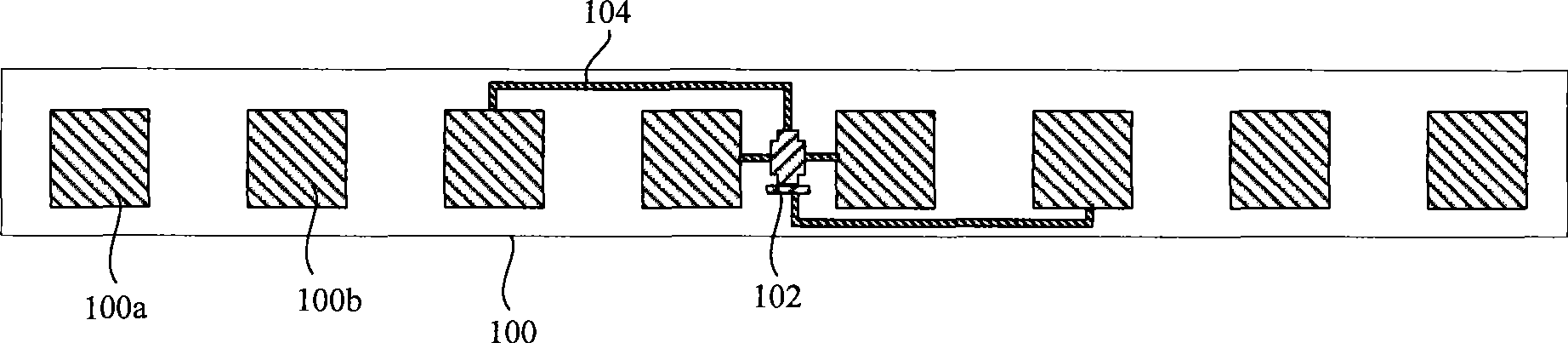

[0076] Next, form a virtual frame pattern that frames at least two of the dummy lead pad patterns, and the virtual frame pattern is used to divide the area of a single test structure pattern to form a frame of a standard unit.

[0077] Then, a single test structure pattern is formed between the dummy ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com