Generating method and system for stamping die brake bead and modification type brake bead

A technology of stamping die and drawbead, which is applied to the generation method and system of variant drawbead, and the field of stamping die drawbead, can solve the problems of high cost, long die design cycle, long time consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

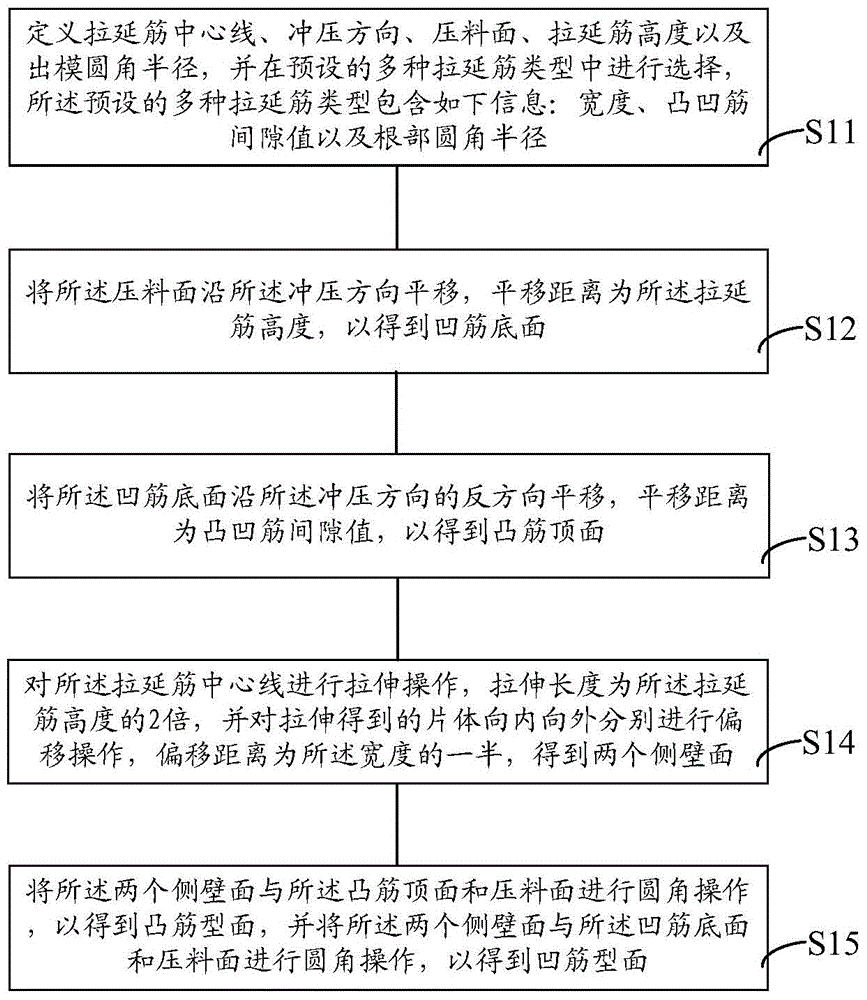

[0078] refer to figure 1 , the generation method of the stamping die drawbead of the present embodiment may include the following steps:

[0079] Step S11, define the drawbead centerline, punching direction, binder surface, drawbead height and die fillet radius, and select from a variety of preset drawbead types, the preset multiple The drawbead type contains the following information: width, bead gap value, and root fillet radius;

[0080] Step S12, translating the binder surface along the stamping direction, and the translation distance is the height of the drawbead, so as to obtain the bottom surface of the concave bead;

[0081] Step S13, translating the bottom surface of the concave rib along the opposite direction of the stamping direction, and the translation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com