Interactive mold design method and system

A mold design, interactive technology, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of difficult mold structure update, unreasonable structural design, low standardization, etc., to shorten the mold design cycle, reduce design Dependence on high personnel capability requirements and the effect of improving the degree of standardization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

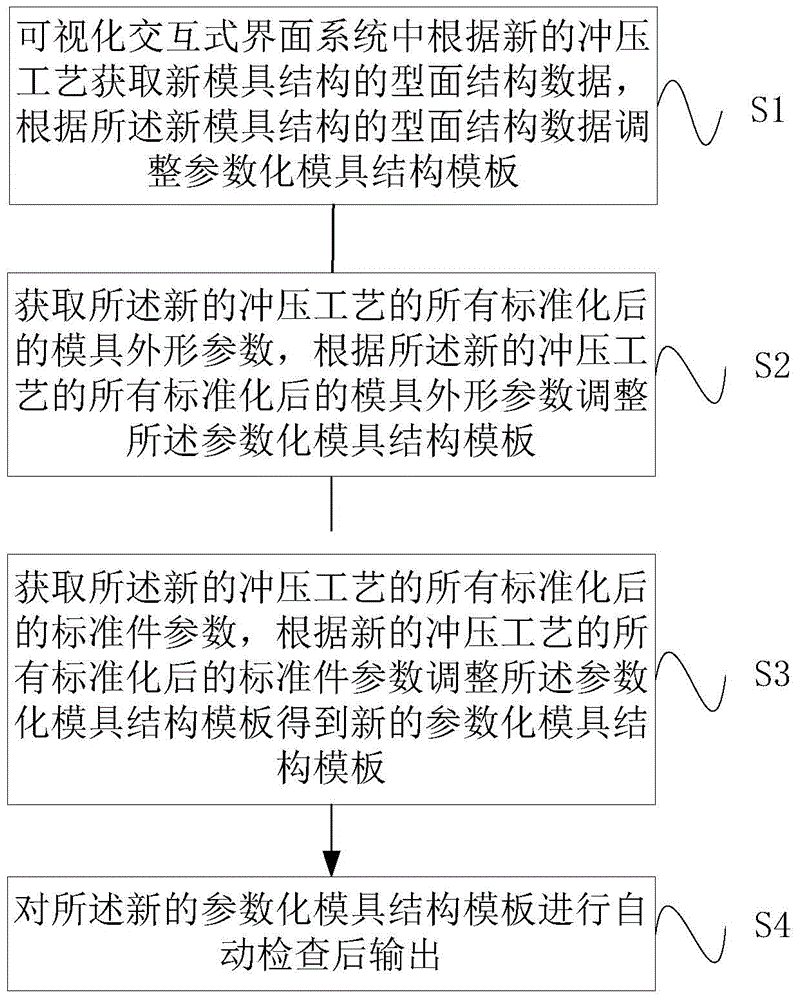

[0052] Such as figure 1 As shown, the present invention provides an interactive mold design method, including steps S1 to S4.

[0053]Step S1, obtain the surface structure data of the new mold structure according to the new stamping process in the visual interactive interface system, and adjust the parameterized mold structure template according to the surface structure data of the new mold structure; specifically, the mold structure design is It is carried out according to the stamping process of the part, so in order to make the stamping process part of the mold structure can be automatically replaced, the stamping process tree structure is standardized, and the profile structure data required by the mold structure is pre-processed to obtain the structure that can be directly used. Data, when designing a new part mold structure, only the stamping process is automatically replaced to realize the automatic update of the process content, and generate the process data required f...

Embodiment 2

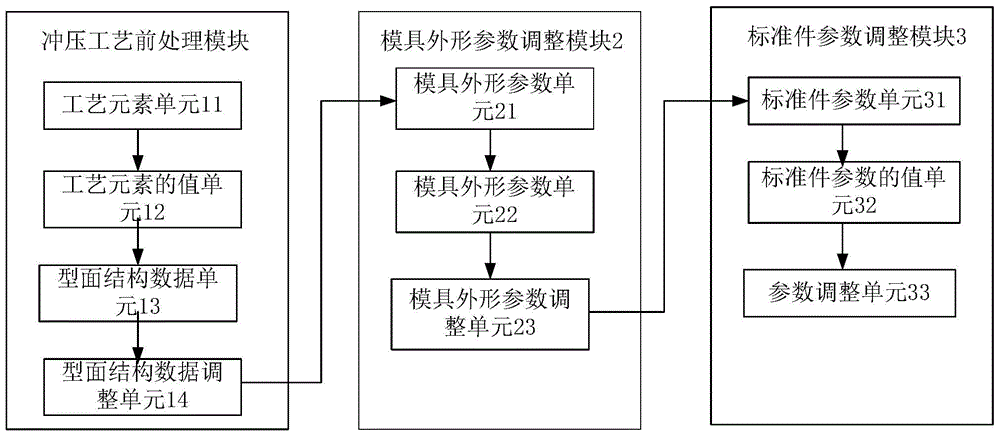

[0072] Such as figure 2 As shown, the present invention also provides another interactive mold design system, which includes a stamping process pre-processing module 1 , a mold shape parameter adjustment module 2 , a standard part parameter adjustment module 3 and an inspection output module 4 .

[0073] Surface structure data stamping process preprocessing module 1, used to obtain the surface structure data of the new mold structure according to the new stamping process in the visual interactive interface system, and adjust the parameterized mold according to the surface structure data of the new mold structure structure template;

[0074] A mold shape parameter adjustment module 2, configured to obtain all standardized mold shape parameters of the new stamping process, and adjust the parameterized mold structure template according to all standardized mold shape parameters of the new stamping process;

[0075] The standard part parameter adjustment module 3 is used to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com