Combined heavy-duty prestressed oil cylinder split along the busbar and its manufacturing method

A combined, pre-stressed technology, used in pressure vessels, gas/liquid distribution and storage, fixed-capacity gas storage tanks, etc., can solve the problems of difficult transportation, high price, high risk, etc., and reduce forging costs and manufacturing costs. And the effect of cycle reduction and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

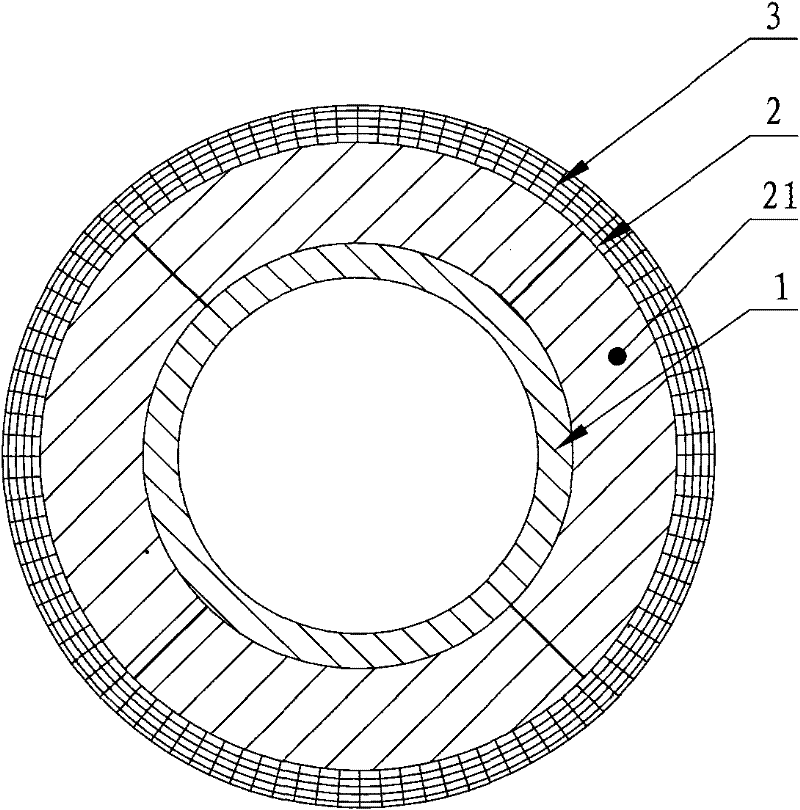

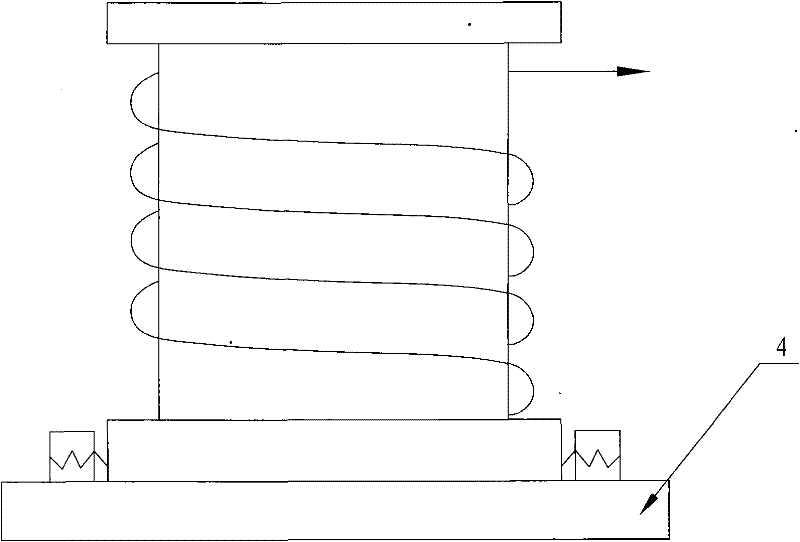

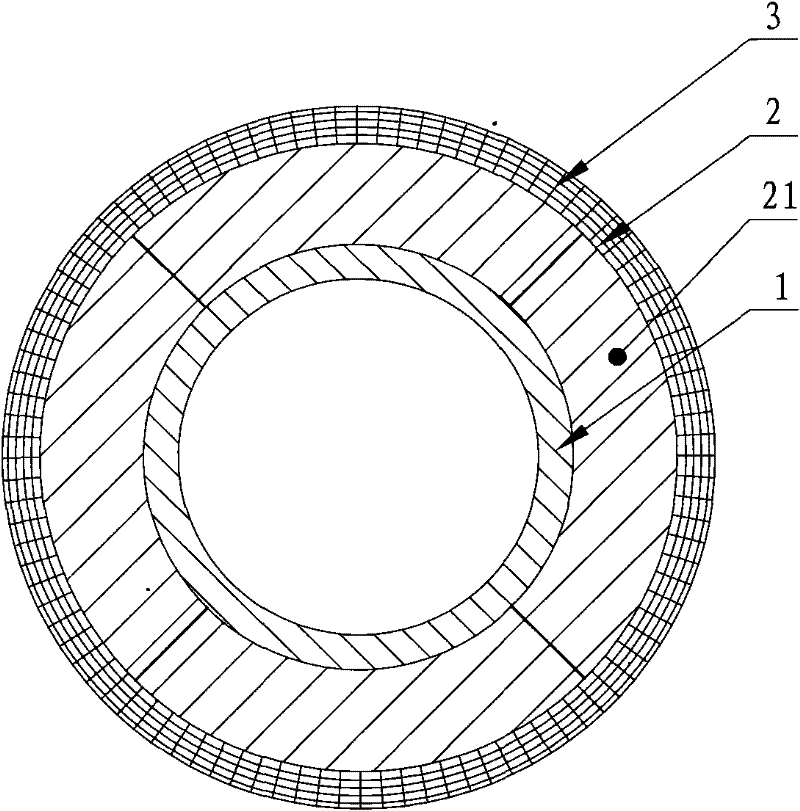

[0020] Embodiment: A combined heavy-duty prestressed oil cylinder split along the generatrix, including an inner layer 1, a middle layer 2 and an outer layer 3; the inner layer 1 is an integral core, and the middle layer 2 is composed of at least two A combined cylinder composed of sub-parts 21 with axial side walls attached to each other (the sub-parts are combined into a cylinder to facilitate processing and assembly), the middle layer 2 is sleeved on the outer side of the inner layer 1, and the inner wall of the middle layer 2 is attached to the outer wall of the inner layer 1. The outer layer 3 is a steel wire winding layer, the outer layer 3 is sheathed on the outer side of the middle layer 2 , and the inner wall of the outer layer 3 is attached to the outer wall of the middle layer 2 .

[0021] The number of sub-components 21 of the middle layer combination is between two and twenty.

[0022] The number of sub-pieces 21 in the middle layer is four.

[0023] The overall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com