Ceramic forging method

A ceramic and forging temperature technology, applied in the field of ceramic forging, can solve the problems of low strain rate, high temperature, ceramic material dislocation and movement difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

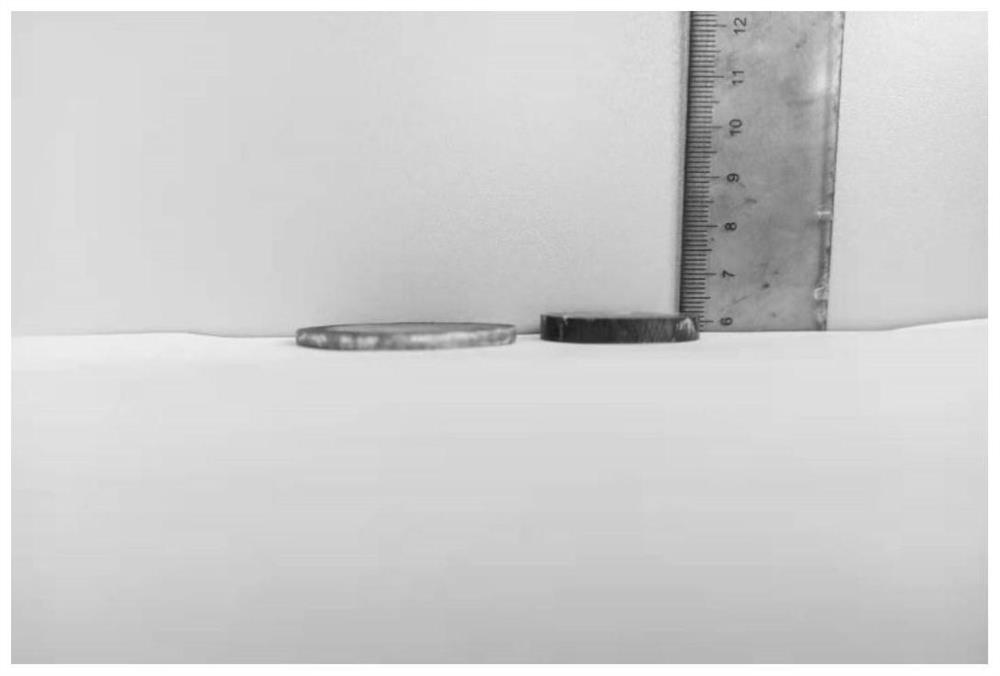

[0023] The ceramic forging method of the present embodiment uses hot-pressed sintered boron carbide ceramics (a cylinder with a diameter of 30 mm and a height of 4.61 mm and a relative density of 98%) added without sintering aids as ceramics to be forged, comprising the following steps:

[0024] Put the ceramics to be forged into a graphite mold with a diameter of 40mm, put the graphite mold filled with the ceramics to be forged into a high-temperature furnace, heat it to the forging temperature of 1900°C under vacuum conditions and keep it warm for 1 hour, and apply oscillating pressure during the holding stage, and the oscillating pressure waveform It is a sine wave, the frequency is 5Hz, the median pressure is 70MPa, and the amplitude is 10MPa. After oscillating forging for 1 hour, a boron carbide forging with a diameter of 40mm and a height of 2.78mm is obtained; the stress of the ceramic to be forged is deformed at 1900°C and 70MPa Index n = 3.38.

[0025] Gained ceramics...

Embodiment 2

[0027] The ceramic forging method of the present embodiment uses hot-pressed sintered boron carbide ceramics (a cylinder with a shape of 30 mm straight and a height of 5 mm and a relative density of 99.7%) added without sintering aids as ceramics to be forged, comprising the following steps:

[0028] Put the ceramics to be forged into a graphite mold with a diameter of 40 mm, put the graphite mold filled with the ceramics to be forged into a high-temperature furnace, heat to the forging temperature of 2000 ° C under vacuum conditions and keep it warm for 1 hour, and apply oscillating pressure during the holding stage, and the oscillating pressure waveform It is a sine wave, the frequency is 20Hz, the median pressure is 50MPa, and the amplitude is 10MPa. After oscillating forging for 1 hour, a boron carbide forging with a diameter of 40mm is obtained; the stress index n=3.63 when the ceramic to be forged is deformed at 2000°C and 50MPa .

[0029] The relative density of the obt...

Embodiment 3

[0031] The ceramic forging method of the present embodiment adopts adding mass ratio 10% Y 2 o 3 The silicon nitride ceramics (liquid-phase sintered silicon nitride ceramics with a relative density of 80%) as sintering aids are used as ceramics to be forged, comprising the following steps:

[0032] Put the ceramic to be forged into a graphite mold, heat it to 1800°C under a nitrogen atmosphere, and apply an oscillating pressure. The oscillation waveform of the oscillating pressure is a sine wave, the frequency is 5Hz, the median value of the oscillating pressure is 70MPa, and the amplitude is 10MPa. After oscillating forging for 1 hour, a deformed silicon nitride ceramic forging was obtained; the stress index n=2.2 of the ceramic to be forged at 1800° C. and 70 MPa.

[0033] The relative density of the obtained silicon nitride ceramic forging is 98%, the Vickers hardness is increased from 9GPa to 14GPa, and the bending strength is increased from 320MPa to 710MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com