Manufacturing process for manufacturing large ship-used shafting forge pieces

A marine shafting and manufacturing process technology, applied in the direction of manufacturing tools, furnace types, engine components, etc., can solve the problems of high production cost, low work efficiency, and low utilization rate of steel ingots, so as to reduce production cycle and cost, and eliminate waste point, the effect of low forging cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with accompanying drawing:

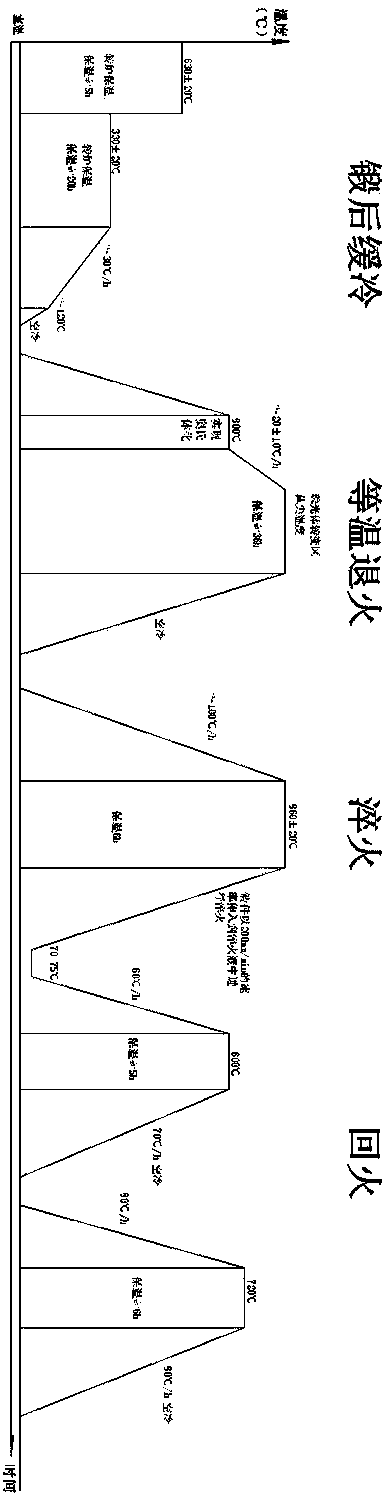

[0046] as attached Figure 1-3 As shown, the manufacturing process of a large-scale marine shafting forging in this embodiment specifically includes the following steps:

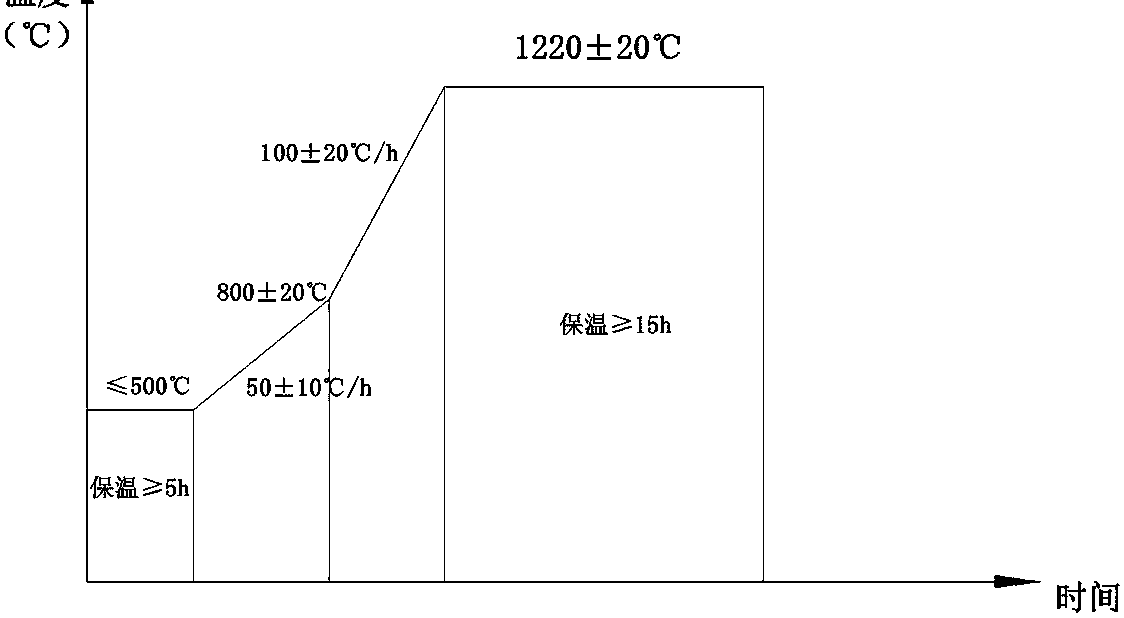

[0047] Step 1, heat treatment before forging:

[0048] S1. Preliminarily heat the steel ingot, and place the forging in a heating furnace with a temperature of ≤500°C for heat preservation, and the heat preservation time is not less than 5 hours;

[0049] S2. Heating at a rate of 50±20°C / hour to slowly heat the forging to 800±20°C;

[0050] S3. Heating at a rate of 100±20°C / hour, so that the steel ingot is slowly heated to 1220±20°C, and then kept warm after being heated to 1220±20°C, and the holding time is not less than 15 hours;

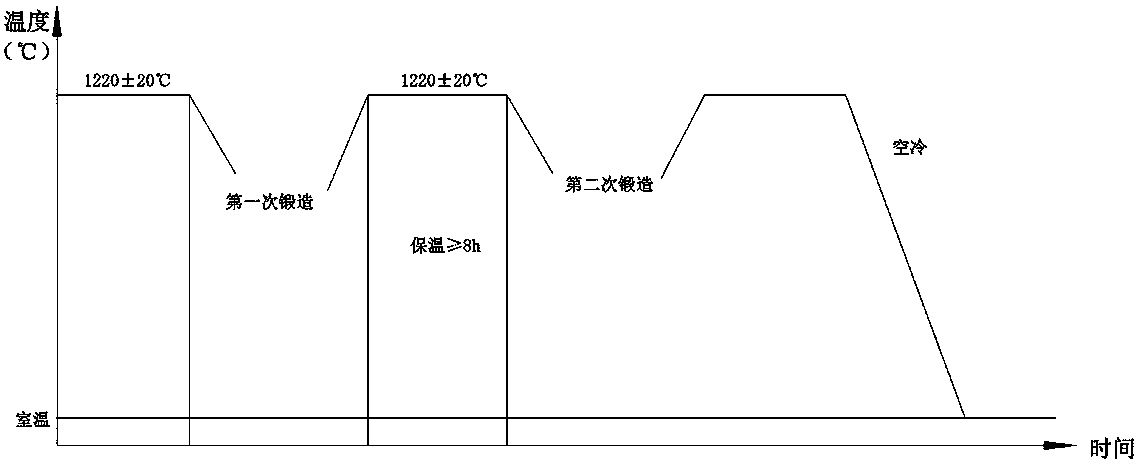

[0051] Step two, forging:

[0052] The steel ingot is forged by two times of upsetting + WHF method of drawing, and the two times of upsetting and drawing are carried out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com