Forging method capable of improving structure uniformity of titanium alloy forging stock

A uniform microstructure and titanium alloy technology, applied in the direction of metal processing equipment, etc., can solve the problems of high-magnification uneven structure, low-magnification “fork” defects in the cross-section of forging blanks, etc., to achieve uniform high-magnification structure, clear grain boundaries, and increase forging cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

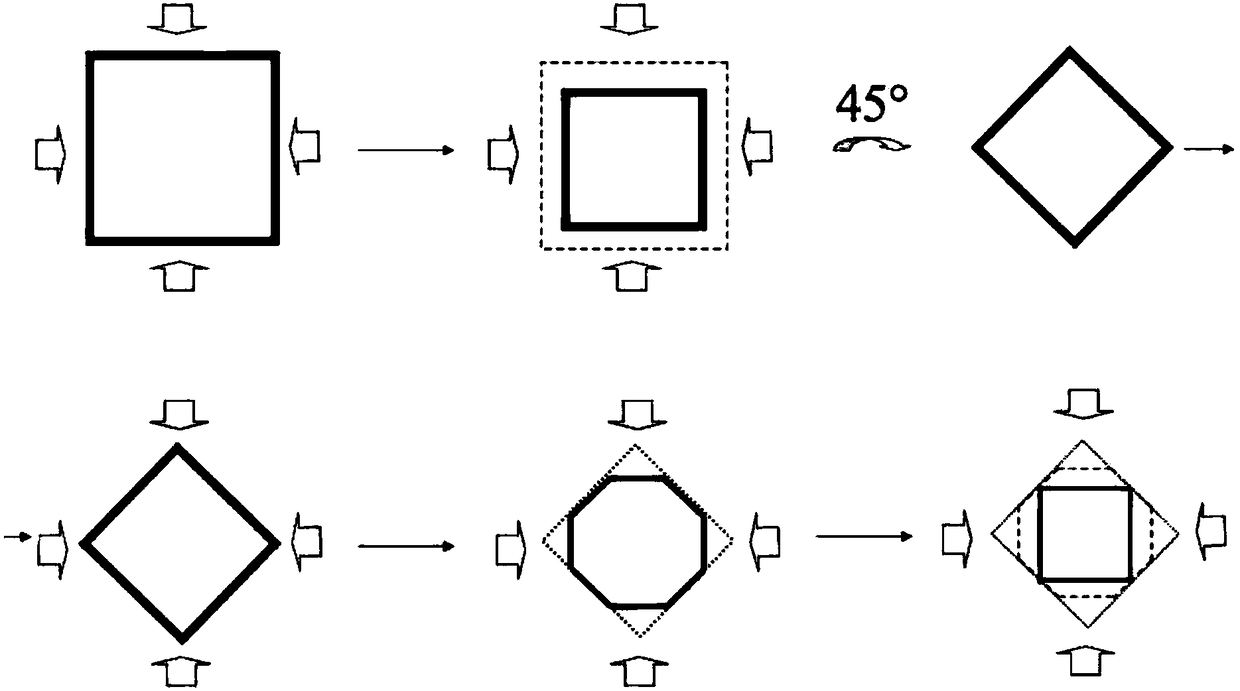

[0032] Example 1: For a TC20 two-phase titanium alloy ingot with a diameter of Φ380mm, the phase transition point of the alloy was measured at 1017°C by differential thermal method; □170~□190mm square billet (that is, a square billet with a cross-sectional side length of 170mm-190mm); the square billet is forged with secondary fire, the forging temperature is 997~1007℃, and it is forged to □140 by four-sided forging ~□150mm; rotate the billet at an angle of 45°, start from the original four corners and divide it into two pressings, one pressing down to an approximate regular octagon, the second pressing down to □100~□105mm, the final forging temperature It is 890±5℃. TC20 titanium alloy □100 low-magnification structure after forging of the present invention such as image 3 As shown, the cross-sectional structure is uniform, the grains are clear, and there is no "fork" defect.

Embodiment 2

[0033] Example 2: For a TC4 two-phase titanium alloy ingot with a diameter of Φ460 mm, the phase transition point of the alloy was measured at 971°C by differential thermal method; □190~□210mm square forging billet; carry out secondary forging on the square billet, the forging temperature is 951~961℃, and use four-sided forging to forge to □150~□160mm; rotate the billet at 45° angle, from the original The four corners begin to elongate and are pressed twice, one press down to approximately a regular octagon, the second press down to □115~□120mm, and the final forging temperature is 870±5℃. The TC4 titanium alloy □120 microstructure after forging of the present invention is as follows Figure 4 (edge) and Figure 5 As shown in (heart), they are all basket tissues, and the edge and heart tissues are uniform.

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com