Silicon steel plate with acid pickling being easy and production method thereof

A technology of easy pickling and silicon steel plate, which is applied in the field of metallurgy, can solve the problems of insufficient pickling and large thickness of iron oxide scale, and achieve the effect of increasing output speed, speeding up production rhythm, shortening heating and holding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

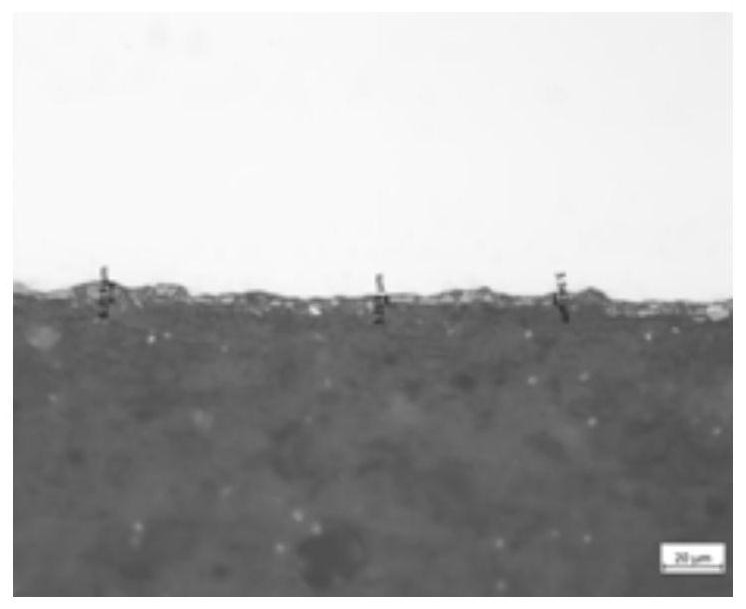

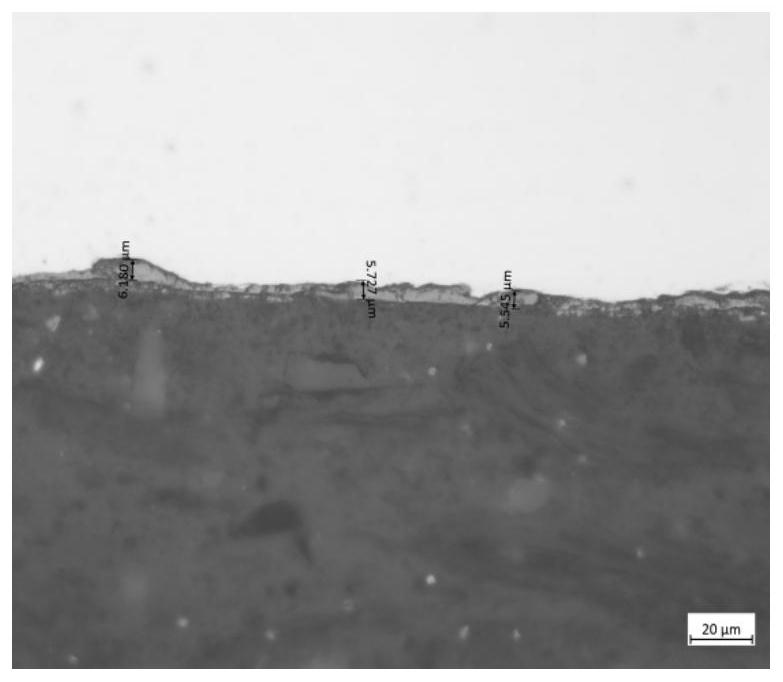

[0048] An easy pickling silicon steel sheet in this embodiment comprises the following components in weight percent: C: 0.005%, Si: 2.0%, Mn: 0.35%, Als: 0.5%, S: 0.005%, P: 0.04%, N: 0.005%, Ti: 0.005%, the rest is Fe and unavoidable impurities, wherein the content of Mn and S satisfies Mn / S≥65. Since the silicon content of the easily pickled silicon steel sheet in this embodiment is relatively high, adding suitable elements such as Si, Mn, and Al, and designing the contents of Mn and S to meet Mn / S≥65 is beneficial for subsequent hot rolling. In the process, hot-rolled strips of silicon steel that are easy to pickle and have a thickness of less than 10 μm are obtained.

[0049] The preparation method of an easy pickling silicon steel plate in this embodiment, the preparation process is as follows: molten steel smelting process → continuous casting process → hot rolling process → laminar cooling → coiling process → cold rolling process → continuous annealing process → finishi...

Embodiment 2

[0055] A kind of easy pickling silicon steel plate of this embodiment is basically the same as Example 1, the difference is that a kind of easy pickling silicon steel plate in this embodiment includes the following components by weight percentage: C: 0.003% , Si: 2.3%, Mn: 0.20%, Als: 0.60%, S: 0.003%, P: 0.03%, N: 0.004%, Ti: 0.003%, and the rest are Fe and unavoidable impurities.

[0056] The preparation method of a kind of easy pickling silicon steel plate of this embodiment, its production steps: smelt the pure molten steel according to above-mentioned chemical composition and cast into the slab that thickness is 60mm through caster continuous casting, wherein the time of refining outside the furnace in the molten steel smelting process Control it at 40min, and control the casting speed at 1.3m / min in the continuous casting process. In this example, the cast slab is directly heated into the furnace, the temperature in the heating furnace is 1140°C, the holding time is 150m...

Embodiment 3

[0058]An easy pickling silicon steel plate of this embodiment is basically the same as that of Example 1, the difference being that the easy pickling silicon steel plate of this embodiment comprises the following components in weight percentage: C: 0.002% , Si: 3.5%, Mn: 0.10%, Als: 0.80%, S: 0.001%, P: 0.01%, N: 0.002%, Ti: 0.004%, and the rest are Fe and unavoidable impurities.

[0059] A method for preparing an easy-to-acid-wash silicon steel plate in this embodiment, its production steps: smelting pure molten steel according to the above chemical composition, continuously casting a slab with a thickness of 90mm through a casting machine, and directly heating it into a furnace, and the heating temperature is 1200°C , the holding time is 160min, the roughing and finishing rolling temperature is controlled at 960°C, the reduction is 85%, high-pressure dephosphorization is performed 3 times, the dephosphorizing water pressure is 25MPa, the finish rolling start temperature is 95...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com