Directional TiAl-based alloy and preparation method thereof

A kind of base alloy and alloy technology, applied in the field of preparation of columnar crystal TiAl base alloy, can solve the problems of low crystal structure symmetry, high equipment heating width, slow growth rate, etc., to avoid peritectic segregation, heating temperature concentration, growth fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

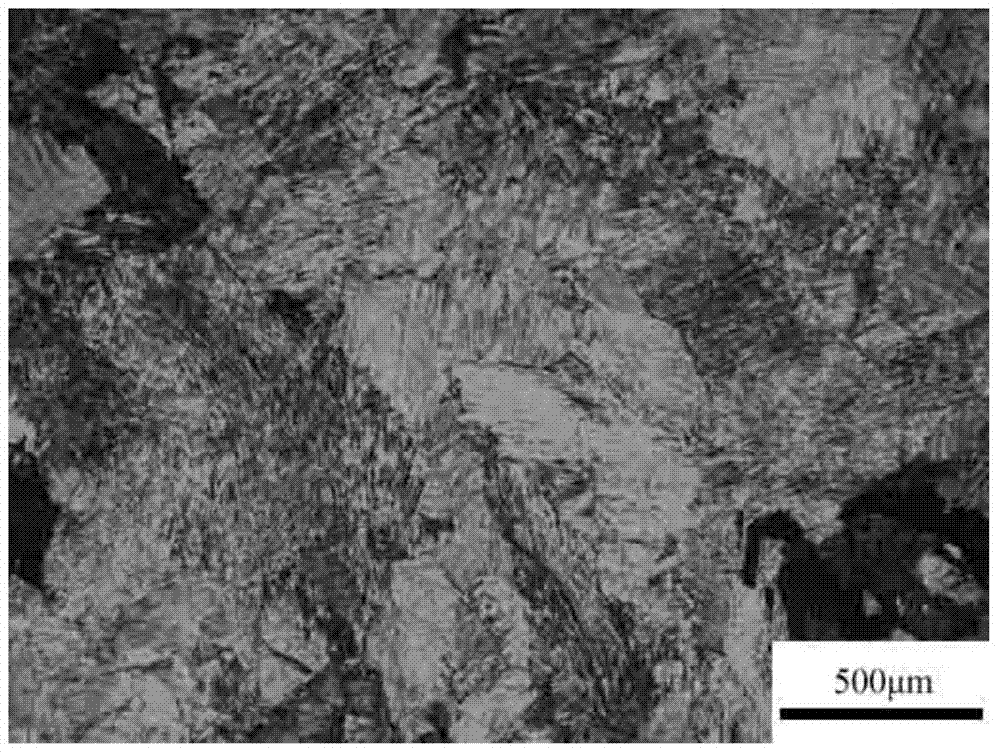

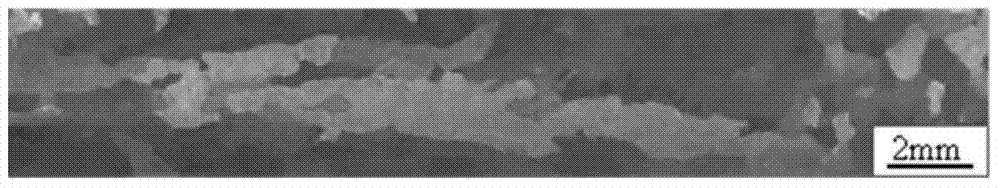

Image

Examples

Embodiment 1

[0025] (1) Alloy composition design

[0026] The oriented TiAl-based alloy of the present invention is calculated by atomic percentage, and the alloy composition is designed as follows: Ti-50Al-8Nb-2Cr, and the balance is Ti.

[0027] (2) Master alloy smelting

[0028] According to the atomic percentage of each element of the alloy designed according to the composition (1), the required alloy is prepared by using high-purity Ti, Al, Nb, and Cr raw materials. The master alloy is melted in a water-cooled copper crucible vacuum induction suspension melting furnace, and the vacuum is first pumped to 10 -3 Below Pa, pass high-purity Ar protective gas until the pressure gauge reads 0Pa. Due to the adoption of suspension smelting, the pollution caused by the reaction between the high-temperature TiAl melt and the crucible is effectively avoided. The smelting power is increased according to the following steps: 9kw→13kw→20kw→24kw, the residence time of each step is between 15-20s, ...

Embodiment 2

[0034] (1) Alloy composition design

[0035] The oriented TiAl-based alloy of the present invention is calculated by atomic percentage, and the alloy composition is designed as follows: Ti-45Al-5Nb-2Mo-V-Mn, and the balance is Ti.

[0036] (2) Master alloy smelting

[0037] According to the atomic percentage of each element of the alloy designed according to the composition (1), the required alloy is prepared by using high-purity Ti, Al, Nb, Mo, V, and Mn raw materials. The master alloy is melted in a water-cooled copper crucible vacuum induction suspension melting furnace, and the vacuum is first pumped to 10 -3 Below Pa, pass high-purity Ar protective gas until the pressure gauge reads 0Pa. The smelting power is increased according to the following steps: 9kw→13kw→20kw→24kw, the residence time of each step is between 15-20s, and finally stabilized at 24kw, and the smelting time is 3min. Repeat the above steps, repeated smelting 3 times.

Embodiment 3

[0043] (1) Alloy composition design

[0044] The oriented TiAl-based alloy of the present invention is calculated by atomic percentage, and the alloy composition is designed as follows: Ti-40Al-2Nb-2Mo-V, and the balance is Ti.

[0045] (2) Master alloy smelting

[0046] According to the atomic percentage of each element of the alloy designed according to the composition (1), the required alloy is prepared by using high-purity Ti, Al, Mo, Nb, and V raw materials. The master alloy is melted in a water-cooled copper crucible vacuum induction suspension melting furnace, and the vacuum is first pumped to 10 -3 Below Pa, pass high-purity Ar protective gas until the pressure gauge reads 0Pa. The smelting power is increased according to the following steps: 9kw→13kw→20kw→24kw, the residence time of each step is between 15-20s, and finally stabilized at 24kw, and the smelting time is 3min. Repeat the above steps, repeated smelting 3 times.

[0047] (3) Alloy casting rod preparatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com