TiZrAlSiON nano composite superhard coating cutter and preparation method thereof

A nano-composite coating, nano-composite technology, applied in the direction of coating, nanotechnology, nanotechnology, etc., to achieve the effect of low friction coefficient, improved high temperature oxidation resistance, and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

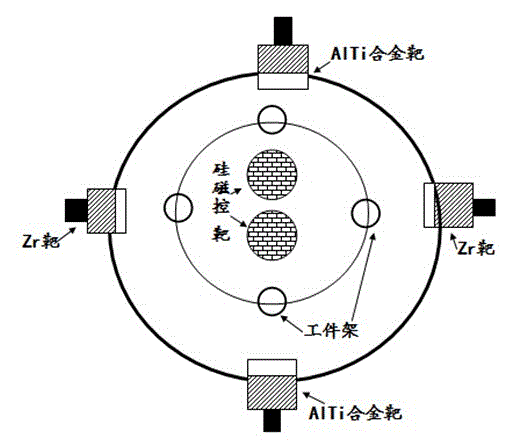

[0026] A TiZrAlSiON nanocomposite superhard coating tool, the coating tool includes a carbide tool body and a TiZrAlSiON nanocomposite coating coated on the body, wherein the TiZrAlSiON nanocomposite coating is a multilayer composite structure: including 50 nanometers thick metal The underlying Zr metal layer, the 100nm thick nitride transition layer ZrN, and the 1000nm thick functional layer TiZrAlSiON;

[0027] Its preparation method is to obtain Zr, Ti, Al by arc evaporation Zr target and TiAl alloy target, Si is obtained by magnetron sputtering columnar Si target, and N and O are obtained by passing N through the gas control device. 2 and O 2 implementation, including the following steps:

[0028] First, when the background vacuum of the vacuum chamber reaches 1×10 -3At this time, the Ar gas was introduced to 1 Pa through the gas control, the substrate temperature was adjusted at 300°C, the substrate bias was adjusted at -70V, and the substrate holder speed was at 3 rpm,...

Embodiment 2

[0030] A TiZrAlSiON nanocomposite superhard coating tool, the coating tool includes a cemented carbide tool body and a TiZrAlSiON nanocomposite coating coated on the body, wherein the TiZrAlSiON nanocomposite coating is a multilayer composite structure: including 100 nanometers thick metal The underlying Zr metal layer, the 300nm thick nitride transition layer ZrN, and the 4000nm thick functional layer TiZrAlSiON;

[0031] Its preparation method is to obtain Zr, Ti, Al by arc evaporation Zr target and TiAl alloy target, Si is obtained by magnetron sputtering columnar Si target, and N and O are obtained by passing N through the gas control device. 2 and O 2 implementation, including the following steps:

[0032] First, when the background vacuum of the vacuum chamber reaches 8×10 -3 At Pa, Ar gas is introduced to 3 Pa through gas control, the temperature of the substrate is adjusted at 400 °C, the bias voltage of the substrate is adjusted at -1000 V, the speed of the substra...

Embodiment 3

[0034] A TiZrAlSiON nanocomposite superhard coating tool, the coating tool includes a carbide tool body and a TiZrAlSiON nanocomposite coating coated on the body, wherein the TiZrAlSiON nanocomposite coating is a multilayer composite structure: including 80 nanometers thick metal The underlying Zr metal layer, the 200nm thick nitride transition layer ZrN, and the 3000nm thick functional layer TiZrAlSiON;

[0035] Its preparation method is to obtain Zr, Ti, Al by arc evaporation Zr target and TiAl alloy target, Si is obtained by magnetron sputtering columnar Si target, and N and O are obtained by passing N through the gas control device. 2 and O 2 implementation, including the following steps:

[0036] First, when the background vacuum of the vacuum chamber reaches 7×10 -3 At Pa, Ar gas was introduced to 2.5 Pa through gas control, the temperature of the substrate was adjusted at 350 °C, the bias voltage of the substrate was adjusted at -800 V, and the speed of the substrate...

PUM

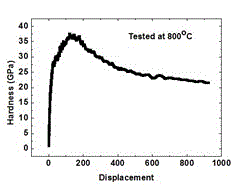

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com