Preparation method of silica-coated cerium sulphide red pigment and prepared product thereof

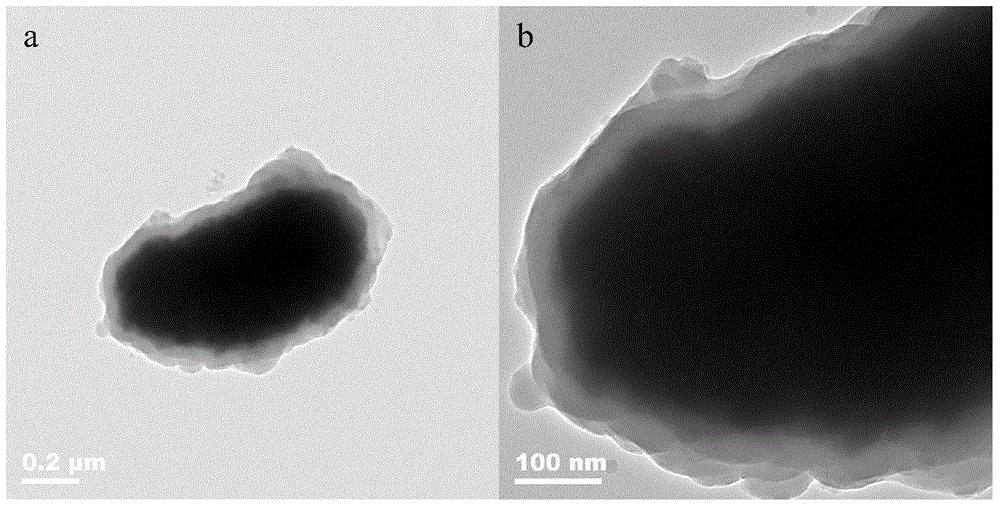

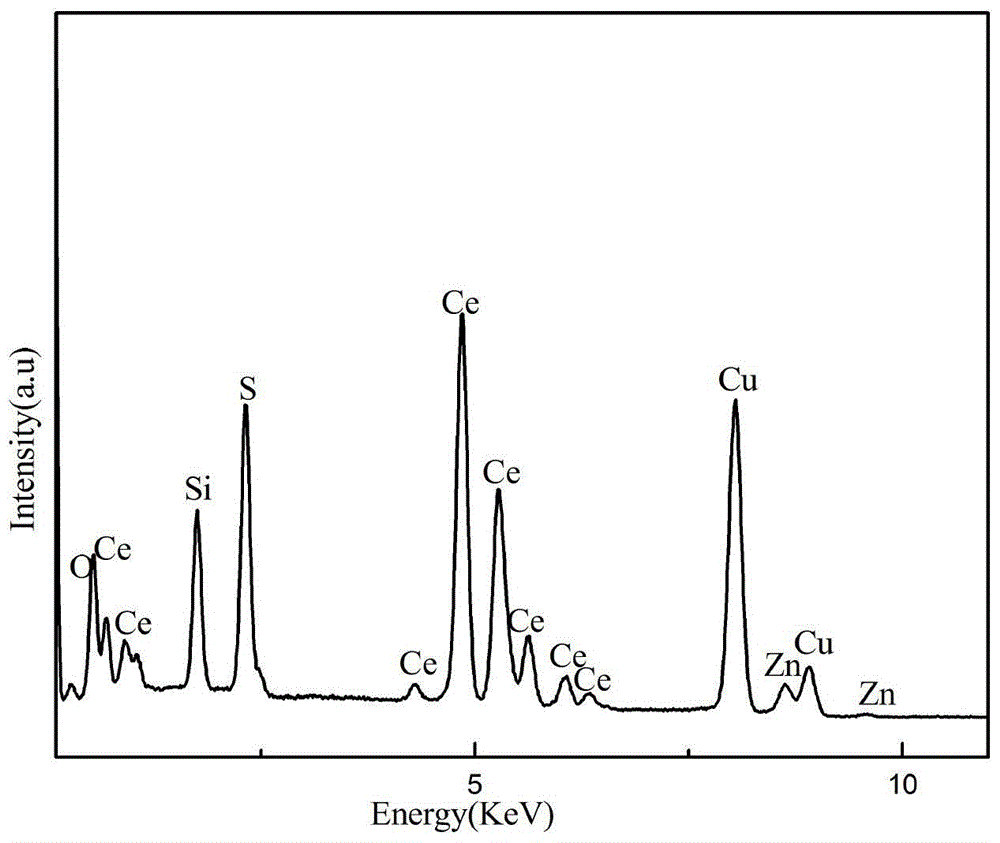

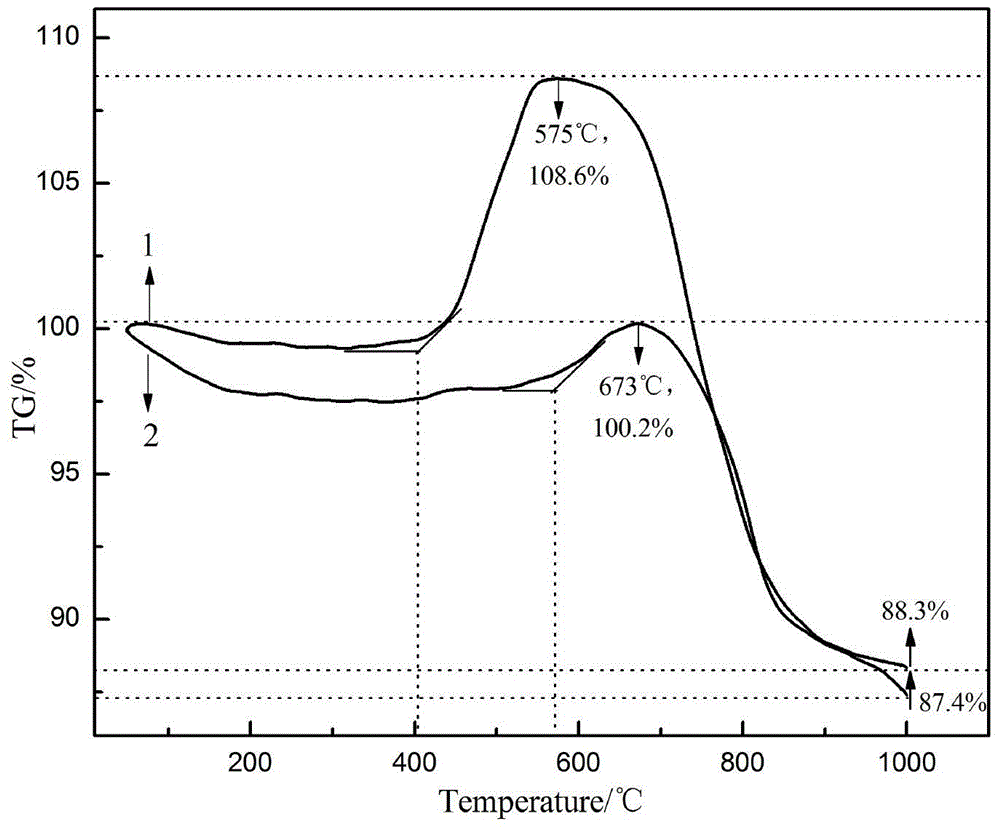

A technology of silica and red pigments, which is applied in the field of inorganic pigments, can solve the problems of little improvement in high-temperature oxidation resistance, unfavorable development of high-temperature ceramic pigments, and insufficient thickness of the coating layer, so as to improve high-temperature oxidation resistance and excellent High-temperature anti-oxidation performance, the effect of ensuring color development ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The preparation method of a kind of silica coating type cerium sulfide red pigment of present embodiment, its steps are as follows:

[0029] (1) Preparation of raw material solution

[0030] Toner suspension: grind and sieve 3g of cerium sulfide pigment, add 190ml of ethanol and 50ml of deionized water to the mixed solution for one dispersion, and add 0.3g of dispersant cetyltrimethylammonium bromide (CTAB) Aging for 24h under slow magnetic stirring at 200r / min, and centrifuging once to remove excess dispersant and impurities to obtain pretreated colorant; then add pretreated colorant to a mixed solution of 100ml ethanol and 20ml deionized water for two Secondary dispersion, after magnetic stirring and ultrasonic dispersion, adjust the pH value of the solution to 10.5 with ammonia water to obtain a colorant suspension;

[0031] Silicon source solution: Dissolve 3.3g tetraethyl orthosilicate in 20ml ethanol solution to obtain silicon source solution;

[0032] (2) Use a...

Embodiment 2

[0036] The preparation method of a kind of silica coating type cerium sulfide red pigment of present embodiment, its steps are as follows:

[0037] (1) Preparation of raw material solution

[0038] Toner suspension: After grinding and sieving 1.67g of cerium sulfide pigment, add 150ml of ethanol and 50ml of deionized water to the mixed solution for one dispersion, and add 0.14g of dispersant cetyltrimethylammonium bromide (CTAB ) aging for 24h under slow magnetic stirring at 200r / min, centrifuged once to remove excess dispersant and impurities to obtain the pretreatment colorant; then add the pretreatment colorant to the mixed solution of 100ml ethanol and 20ml deionized water for Secondary dispersion, after magnetic stirring and ultrasonic dispersion, adjust the pH value of the solution to 9.5 with ammonia water to obtain a colorant suspension;

[0039] Silicon source solution: Dissolve 4g of tetraethyl orthosilicate in 20ml of ethanol solution to obtain a silicon source sol...

Embodiment 3

[0043] The preparation method of a kind of silica coating type cerium sulfide red pigment of present embodiment, its steps are as follows:

[0044] (1) Preparation of raw material solution

[0045] Toner suspension: grind and sieve 3g of cerium sulfide pigment, add 170ml of ethanol and 50ml of deionized water to the mixed solution for one dispersion, and add 0.15g of dispersant cetyltrimethylammonium bromide (CTAB) Aging for 24 hours under slow magnetic stirring at 200r / min, and centrifuging once to remove excess dispersant and impurities to obtain pretreated colorant; then add pretreated colorant to a mixed solution of 90ml ethanol and 20ml deionized water for two Secondary dispersion, after magnetic stirring and ultrasonic dispersion, adjust the pH value of the solution to 10.0 with ammonia water to obtain a colorant suspension;

[0046] Silicon source solution: Dissolve 5g of tetraethyl orthosilicate in 30ml of ethanol solution to obtain a silicon source solution;

[0047...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com