Whisker- toughened cermet cutting tool and method for preparing same

A cermet and whisker technology, applied in the field of whisker toughened cermet knives and its preparation, can solve the problems that the toughening effect is not obvious, achieve good promotion and application prospects, good impact toughness, and good chemical stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

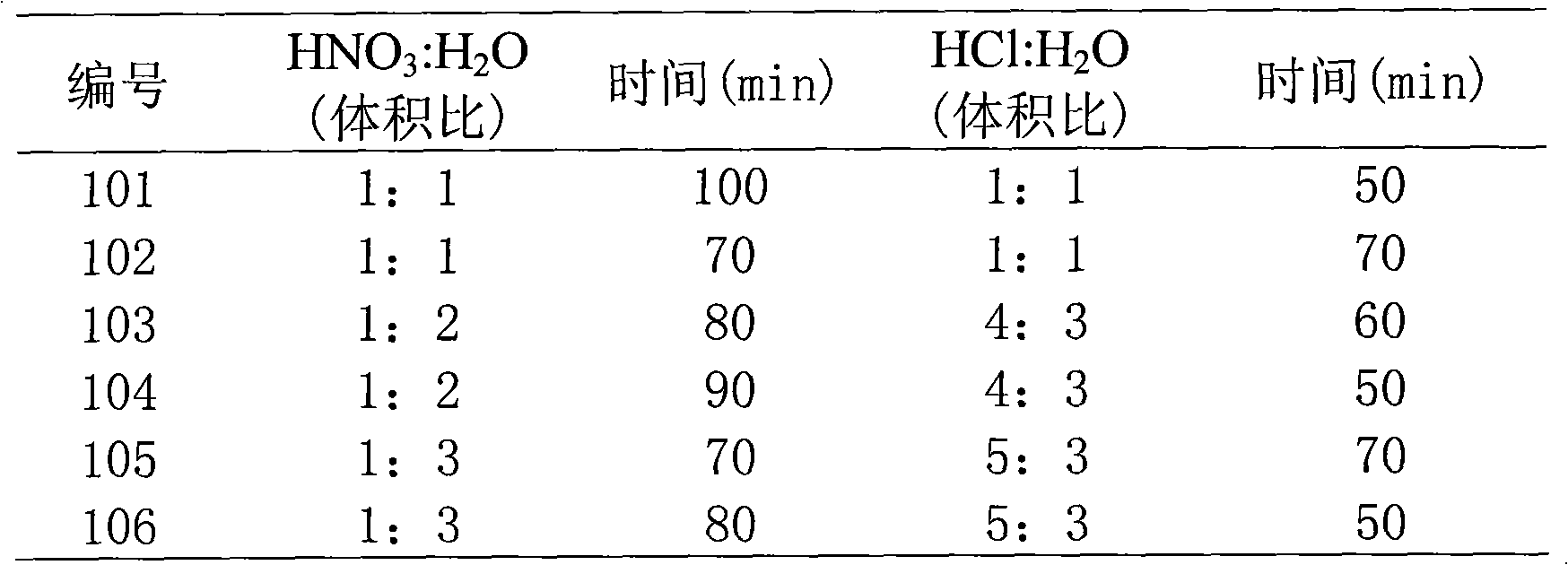

[0024] Commercially available SiC whiskers are used, wherein the average diameter of SiC whiskers is 5-100nm, the length is 200-800nm, the melting point is 2700°C, and the theoretical density is 3.2g / cm 3 , elastic modulus 414GPa, thermal expansion coefficient 3.28×10 -6 K -1 . Divide the SiC whiskers into 6 groups, numbered 101, 102, 103, 104, 105 and 106. Among them, the loading amount of 101 and 102 is 1g / L; the loading amount of 103 and 104 is 2g / L; the loading amount of 105 and 106 is 3g / L.

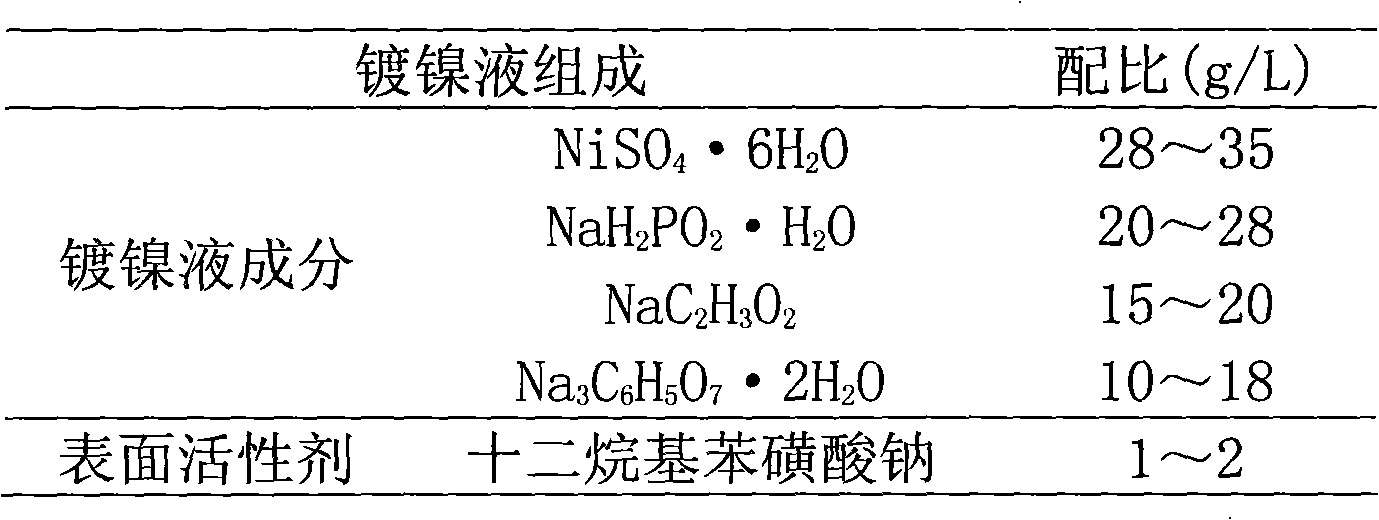

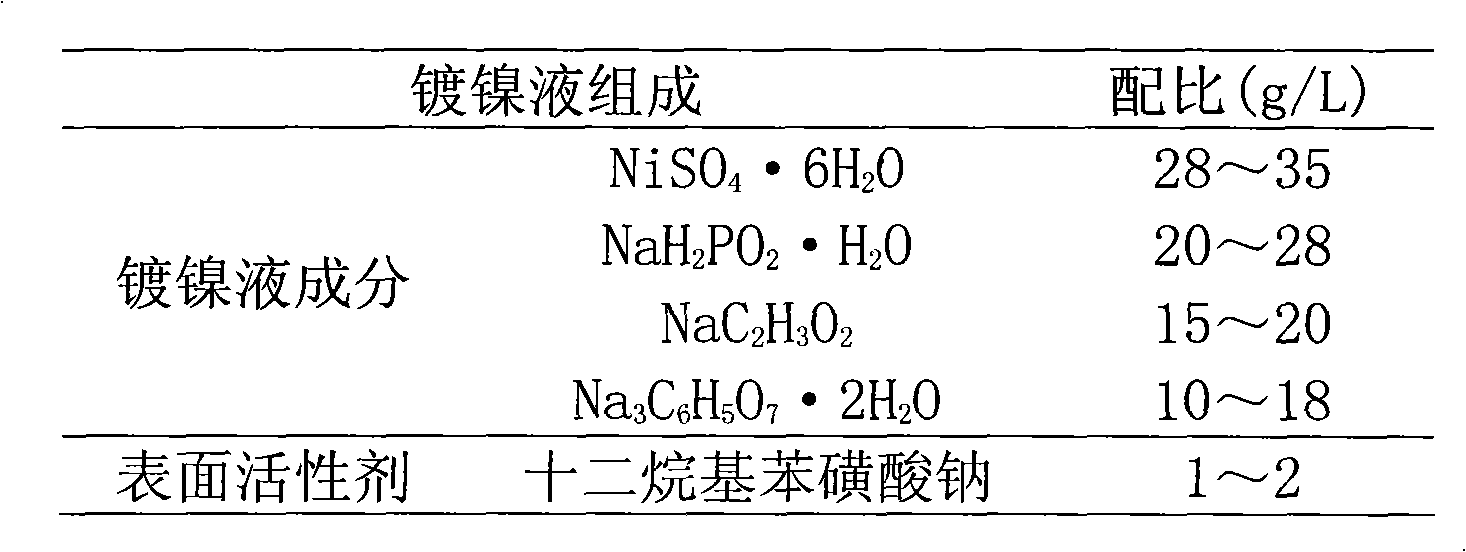

[0025] 1. Nickel plating on the surface of SiC whiskers: perform electroless nickel plating on the surface in the following manner.

[0026] (1) Purification: Stir and ultrasonically disperse the SiC whiskers in the mixed solution in column 1 as shown in Table 1, heat and boil according to the time in column 2, and then clean them in column 3 as shown in Table 1 Stir and ultrasonically disperse in the mixed solution, heat and boil according to the time in column 4, and then fully...

Embodiment 2

[0048] 1. Nickel plating on the surface of SiC whiskers: using the commercially available SiC whiskers in Example 1, electroless nickel plating was performed on the surface of SiC whiskers according to the SiC whisker nickel plating process No. 101-106 in Example 1.

[0049] 2. Mixing of raw materials: base material and nickel-plated SiC whiskers are mixed according to Table 7.

[0050] Table 7 Whisker toughened cermet composition

[0051]

[0052] The ball mill mixing process is shown in Table 8.

[0053] Table 8 Ball mill mixing process

[0054]

[0055] 3. Molding and degreasing: add polyvinyl alcohol molding agent to the ground powder, mix the added amount, granulate, and use molding. Then use a vacuum sintering furnace to degrease, and carry out at a vacuum degree higher than 5Pa. The compression molding and degreasing processes are shown in Table 9.

[0056] Table 9 Compression molding and degreasing process

[0057]

[0058]

[0059] 4. Vacuum sintering...

Embodiment 3

[0066] NbC and TaC are further added. The commercially available SiC whiskers in Example 1 were used, and the surface of the SiC whiskers was electroless nickel-plated according to the SiC whisker nickel plating process No. 101-106 in Example 1. The matrix material and nickel-plated SiC whiskers are formulated according to Table 12.

[0067] Table 12 Whisker toughened cermet composition

[0068]

[0069] First mix the prepared raw material powders of 8 groups of matrix materials C1~C8 with a planetary ball mill for 24 hours at a ball milling speed of 250rpm, then add the nickel-plated SiC whiskers as shown in Table 12, and then Mix the materials by ball milling for 6 hours, and the ball milling speed is 200 rpm.

[0070] Add 7wt% polyvinyl alcohol as a molding agent to the ground powder, mix and granulate, and adopt compression molding with a unidirectional pressing force of 150 MPa.

[0071] Use a vacuum sintering furnace for degreasing, and carry out at a vacuum degree...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com