Preparation method of laser cladding high-entropy alloy powder and cladding layer and application

A laser cladding and high-entropy alloy technology, applied in the coating process of metal materials, coatings, etc., can solve the problem of difficulty in obtaining a continuous cladding layer on the surface, and improve the performance of the cladding layer, improve corrosion resistance, hardness, etc. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0032] 1. Calculate the proportion of FeNiCrAlSiMnx (take x=0) high-entropy alloy powder according to the molar ratio: Fe is 20mol%, Ni is 20mol%, Cr is 20mol%, Al is 20mol%, Si is 20mol%, and electronic weighing is used Take the powder of various elements.

[0033] 2. Pour into a mortar and grind in the mortar for half an hour to mix well.

[0034] 3. Mix the prepared laser cladding powder with 92% and 8% ethanol to form a paste or paste, and then coat it on the surface of 42CrMo steel with a pre-set layer thickness of 1 mm. After air-drying, perform laser cladding.

[0035] 4. The laser adopts JK2003SM type Nd:YAG, and the laser cladding process parameters are as follows: laser power is 1550KW, spot diameter is 0.8mm, scanning speed is 180mm / min, defocus is 0mm, protective gas is argon, and the gas flow rate is 25L / min.

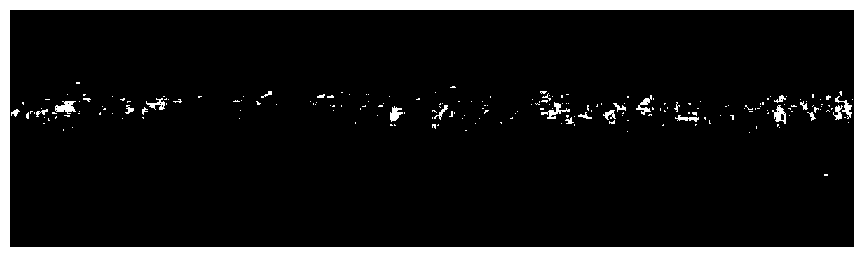

[0036] 5. After laser cladding, use aqua regia to corrode, and obtain the metallographic photos of the cladding layer (the metallographic structure obser...

Embodiment example 2

[0042] 1. Calculate the proportion of FeNiCrAlSiMnx (take x=1) high-entropy alloy powder according to the molar ratio: Fe is 16.67mol%, Ni is 16.67mol%, Cr is 16.67mol%, Al is 16.67mol%, Si is 16.66mol% , Mn is 16.66mol%, the total molar ratio is 100%, and electronic scales are used to weigh the powders of various elements.

[0043] 2. Pour into a mortar and grind in the mortar for half an hour to mix well.

[0044] 3. Mix the prepared laser cladding powder with 95% and 5% ethanol to form a paste or paste, and then coat it on the surface of 42CrMo steel with a pre-set layer thickness of 2mm. After air-drying, perform laser cladding.

[0045]4. The laser adopts JK2003SM type Nd:YAG, and the laser cladding process parameters are as follows: laser power is 1550KW, spot diameter is 0.8mm, scanning speed is 180mm / min, defocus is 0mm, protective gas is argon, and the gas flow rate is 25L / min.

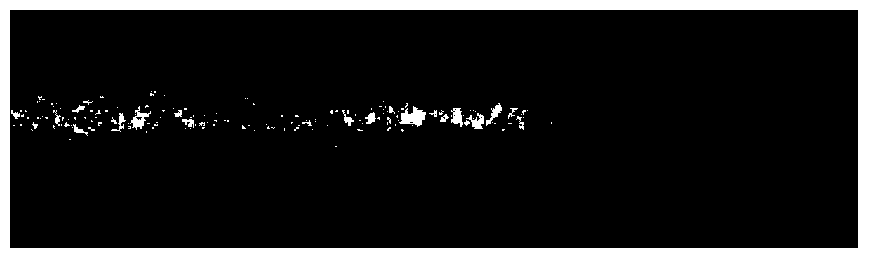

[0046] 5. After laser cladding, use aqua regia to corrode, and obtain the metallographi...

Embodiment example 3

[0052] 1. According to the molar ratio, FeNiCrAlSiMnx (take x = 0.3) high-entropy alloy powder ratio of each metal element: Fe, Ni, Cr, Al and Si are equimolar, Mn is 0.3 of Si molar number, mixed uniformly and used, Refer to the above implementation case

[0053] 2. Laser cladding process: the laser power is 1650KW, the spot diameter is 1.0mm, the scanning speed is 200mm / min, the defocus is 0mm, the protective gas is helium, and the gas flow rate is 20L / min

[0054] 3. Use the same performance test, the results are shown in the table below:

[0055] hardness

[0056]

Hardness value

Hardness value 2

Hardness value 3

average hardness

base material

286HV

282HV

285HV

284HV

FeNiCrAlSiMn 0.3 cladding layer

500.2HV

519.7HV

522.5HV

514.1HV

[0057] wear resistance

[0058]

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com