High temperature titanium alloy and surface modification method thereof

A high-temperature titanium alloy and surface modification technology, which is applied in metal material coating process, ion implantation plating, coating, etc., can solve the problems of strengthening plasticity reduction and affecting the use of alloys, so as to improve performance and high temperature The effect of antioxidant properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Commercially available sponge titanium, sponge zirconium, pure aluminum, pure silicon, aluminum-molybdenum master alloy, aluminum-neodymium master alloy, titanium-niobium-tantalum master alloy and aluminum-tin master alloy are according to the composition ratio of Table 1 (weight percentage, the same below) The electrode block is prepared, and the electrode block is welded into a vacuum consumable electrode in a vacuum plasma box, and then subjected to three times of vacuum consumable melting to form an ingot. The ingot is forged at the phase transition point, and after intermediate forging, it is made into a φ35mm rolled billet. After the billet is heated to 1150°C, it is rolled into a φ15mm bar on a transverse rolling mill.

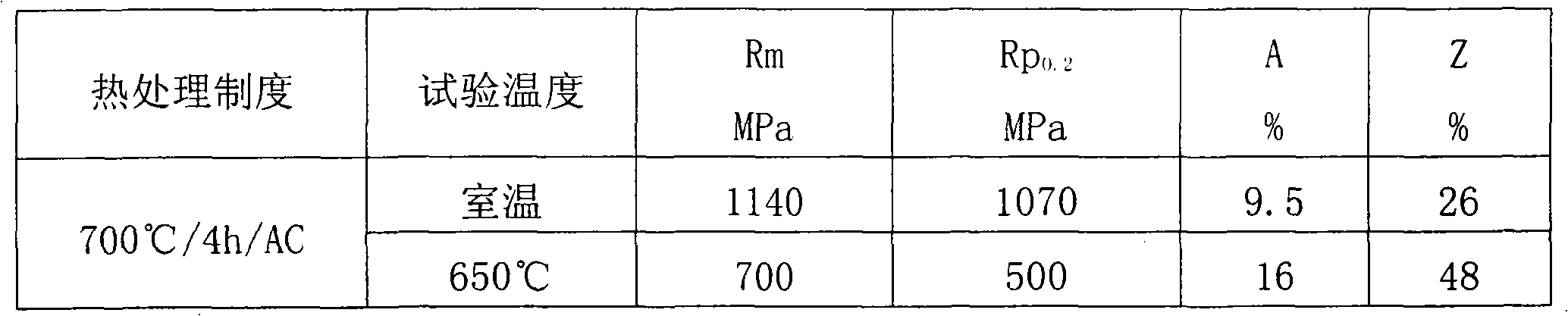

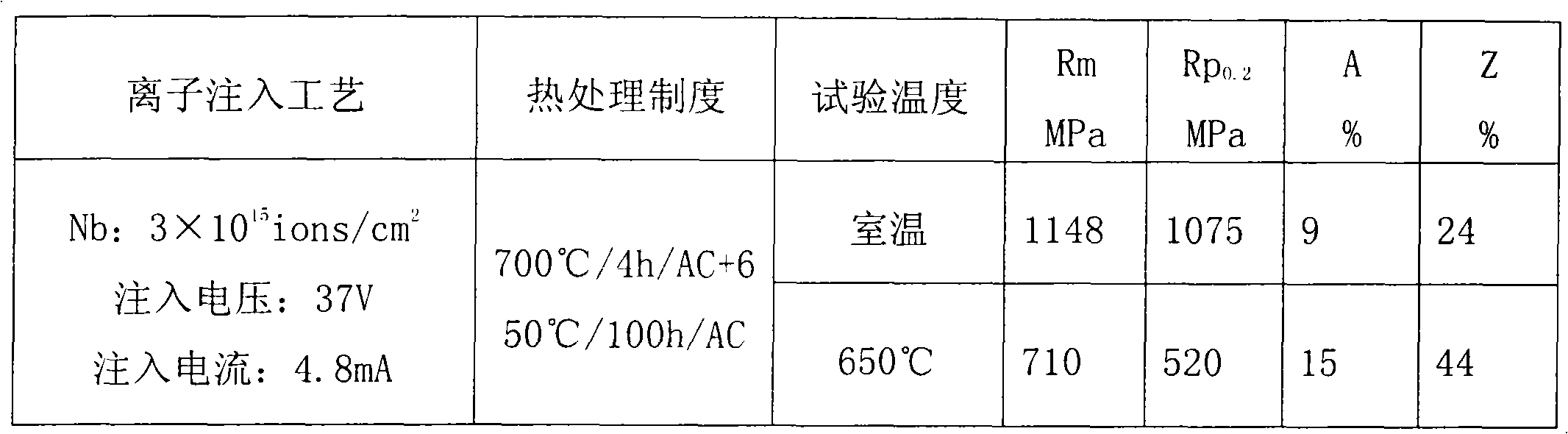

[0036] After the rolled bar is processed by the heat treatment system listed in Table 2, the mechanical properties are tested according to the requirements of GB / T228-2002. The mechanical properties are shown in Table 2. After the rolled bar is s...

Embodiment 2

[0045] Commercially available sponge titanium, pure hafnium, pure aluminum, pure silicon, aluminum-molybdenum master alloy, aluminum-yttrium master alloy, titanium-niobium master alloy, aluminum-gallium master alloy and aluminum-tin master alloy were prepared into electrodes according to the composition ratio in Table 4 The electrode block is welded into a vacuum consumable electrode in a vacuum plasma box, and then undergoes three vacuum consumable smelting to make an ingot. The ingot is forged at the phase transition point, and after intermediate forging, it is made into a φ35mm rolled billet. After the billet is heated to 1150°C, it is rolled into a φ15mm bar on a transverse rolling mill.

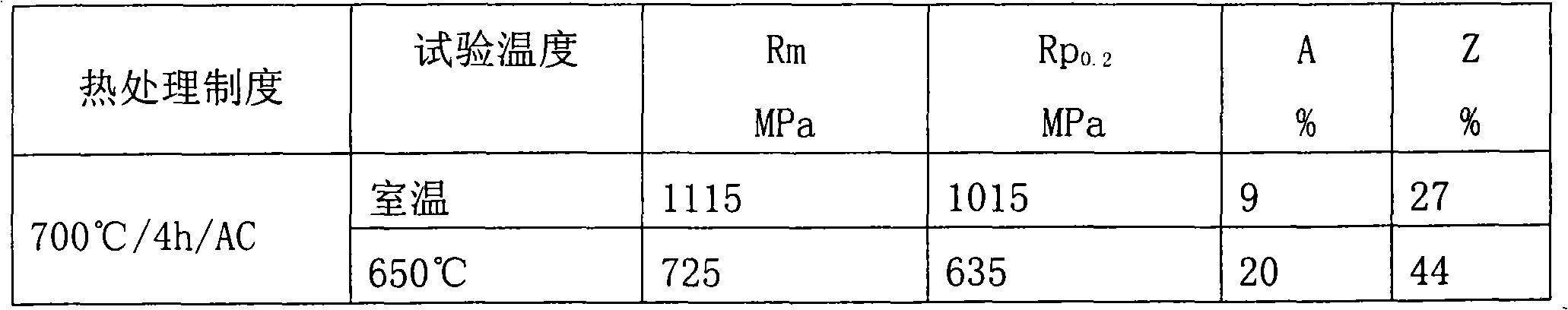

[0046] After the rolled bar is processed by the heat treatment system listed in Table 5, the mechanical properties are tested according to the requirements of GB / T228-2002. The mechanical properties are shown in Table 5. After the rolled bar is subjected to the ion implantation and heat ...

Embodiment 3

[0054] Commercially available sponge titanium, sponge zirconium, pure aluminum, pure silicon, aluminum-molybdenum master alloy, aluminum-erbium master alloy, titanium-niobium master alloy and aluminum-tin master alloy were prepared into electrode blocks according to the composition ratio in Table 7, and the electrode blocks were prepared in Vacuum consumable electrodes are welded in a vacuum plasma box, and then vacuum consumable melting is performed three times to make ingots. The ingot is forged at the phase transition point, and after intermediate forging, it is made into a φ35mm rolled billet. After the billet is heated to 1150°C, it is rolled into a φ15mm bar on a transverse rolling mill.

[0055] After the rolled bar is processed by the heat treatment system listed in Table 8, the mechanical properties are tested according to the requirements of GB / T228-2002. The mechanical properties are shown in Table 8. After the rolled bar was subjected to the ion implantation and he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com