Vibrative micro electric field sensor

An electric field sensor, sensor technology, applied in the sensor field, can solve the problems of limitation, narrow measurement range and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

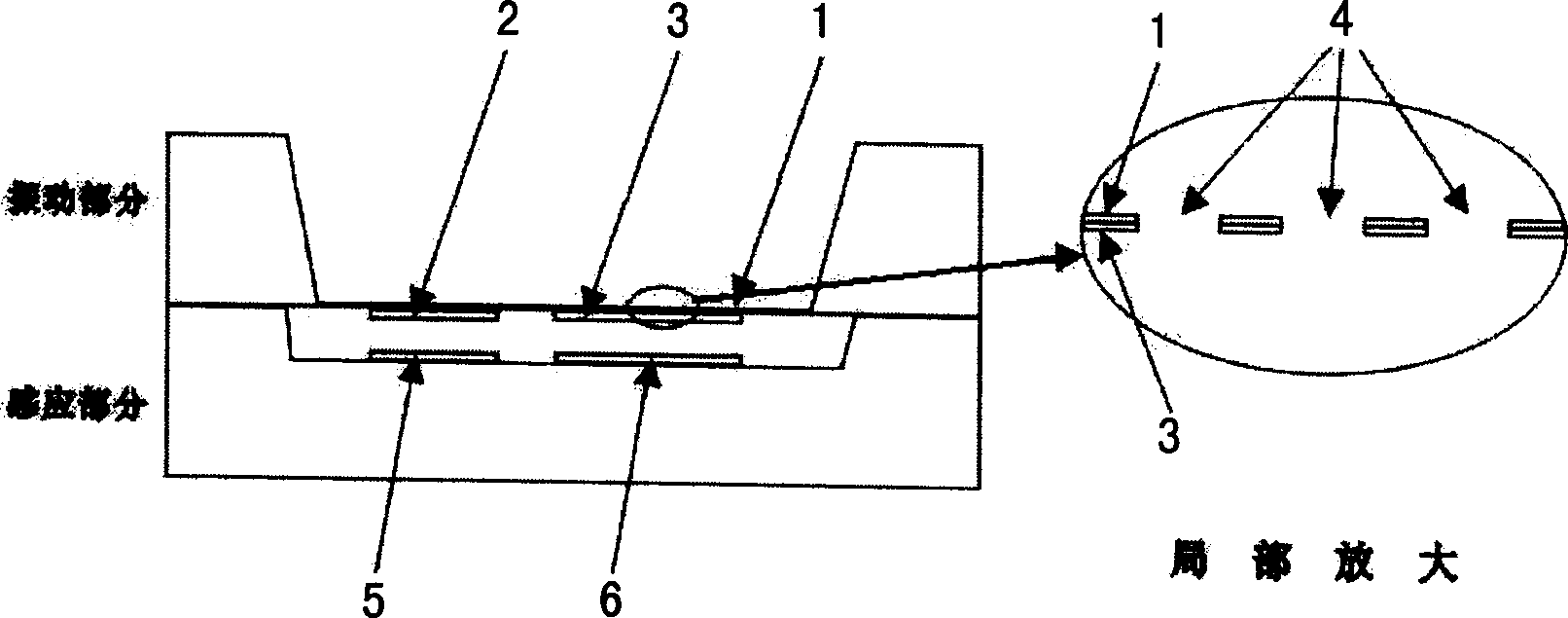

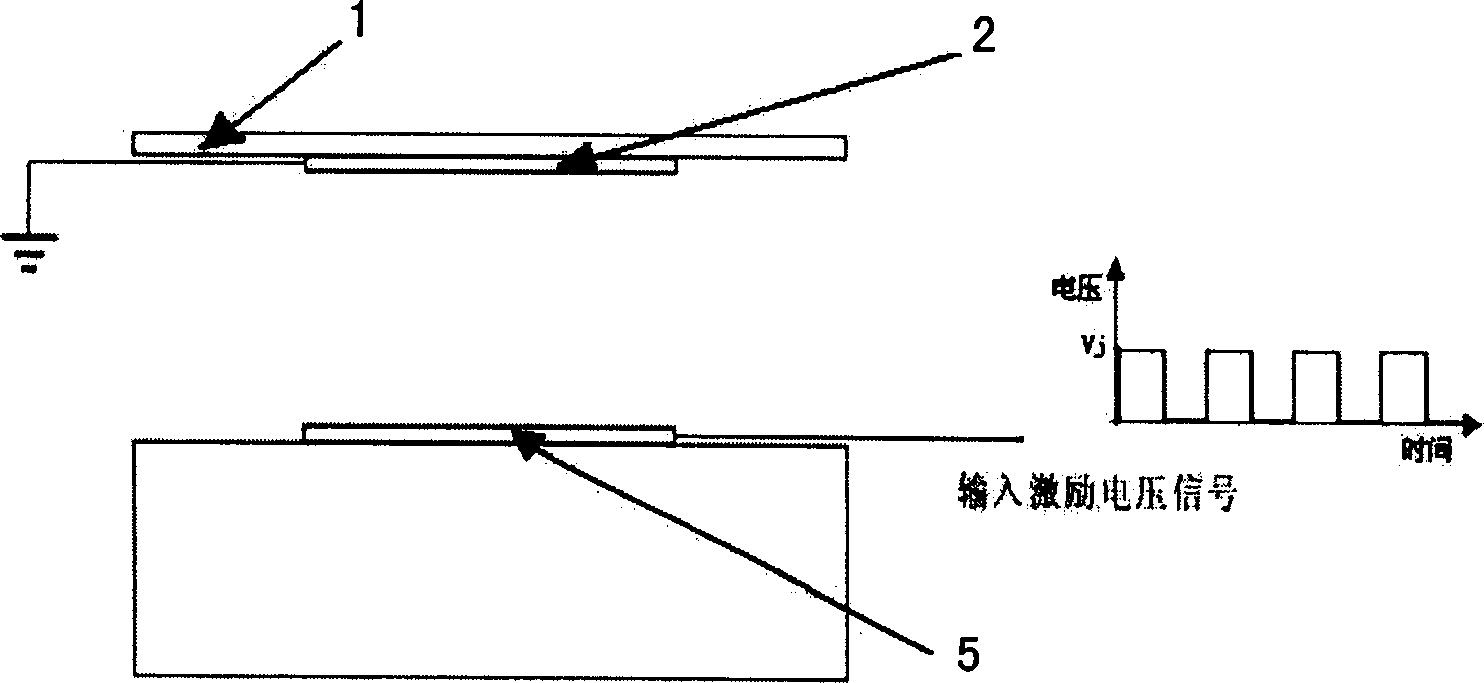

[0009] The structure of the vibrating miniature electric field sensor is as follows: figure 1 As shown, it is composed of vibration and induction parts, which are respectively prepared on the basis of single crystal silicon, and finally bonded as a whole.

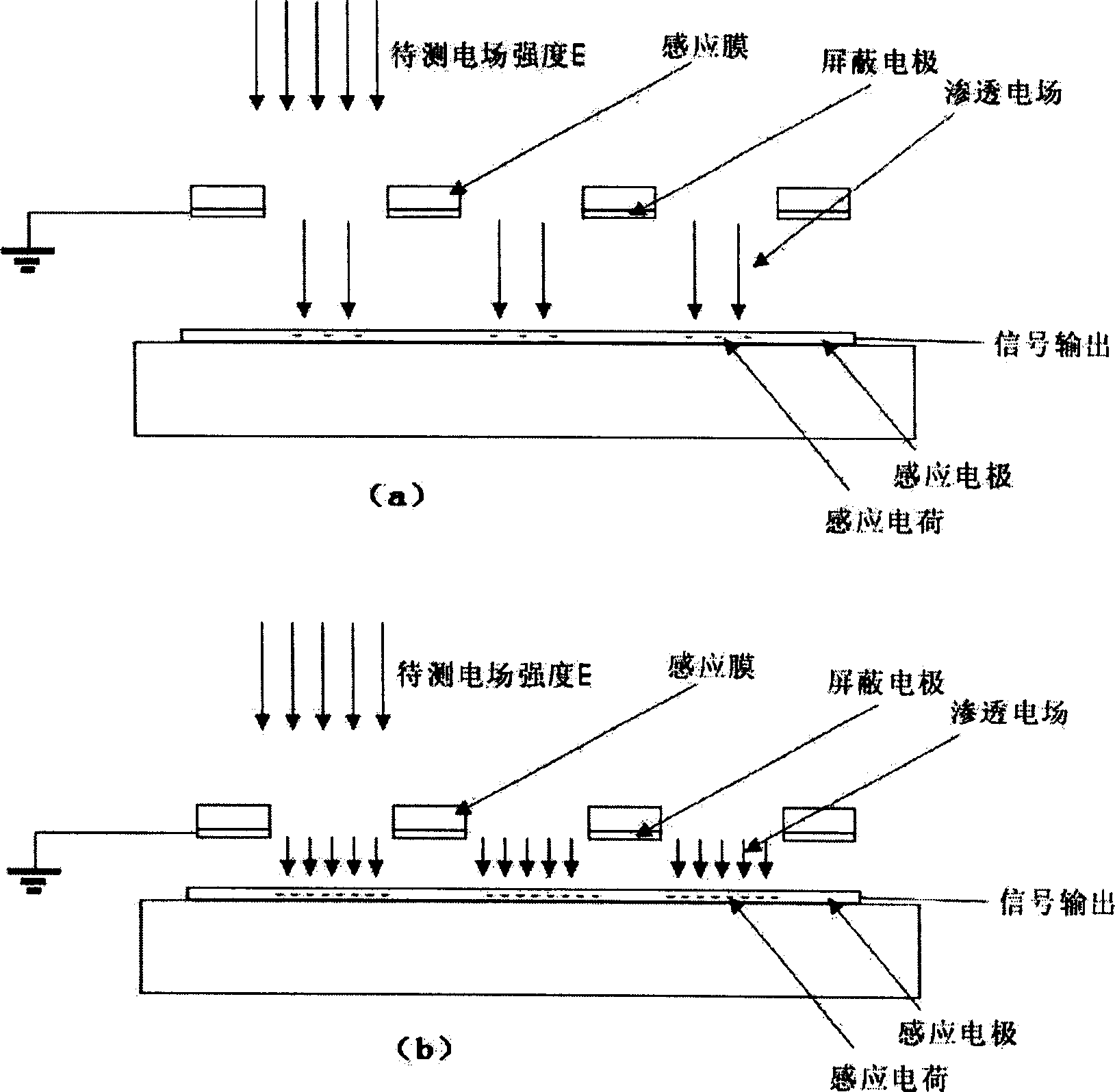

[0010] Vibration part: a silicon nitride film is grown on one side of the silicon wafer, and the silicon nitride film is formed by deep etching on the other side, which is the vibrating film 1 . Electrodes are prepared on the vibrating membrane 1, including the excitation electrode cathode 2 and the shielding electrode 3, both of which are insulated from each other, and the shielding electrode 3 is grounded. There is a gate hole 4 on the shielding electrode 3, and the shape of the hole 4 is a square hole, a round hole or other shapes. The number of grid holes is made as required, but at least one. The gate hole 4 should be as small as possible under the process conditions, for example, the area of the gate hole is less ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com