Processing technique of Roots blower impeller component

A Roots blower and processing technology, applied in the fan field, can solve problems such as low efficiency, affecting the normal operation of the fan, and low overall efficiency of the fan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The following embodiments are given in conjunction with the accompanying drawings to further describe in detail the processing technology of the Roots blower impeller assembly of the present invention.

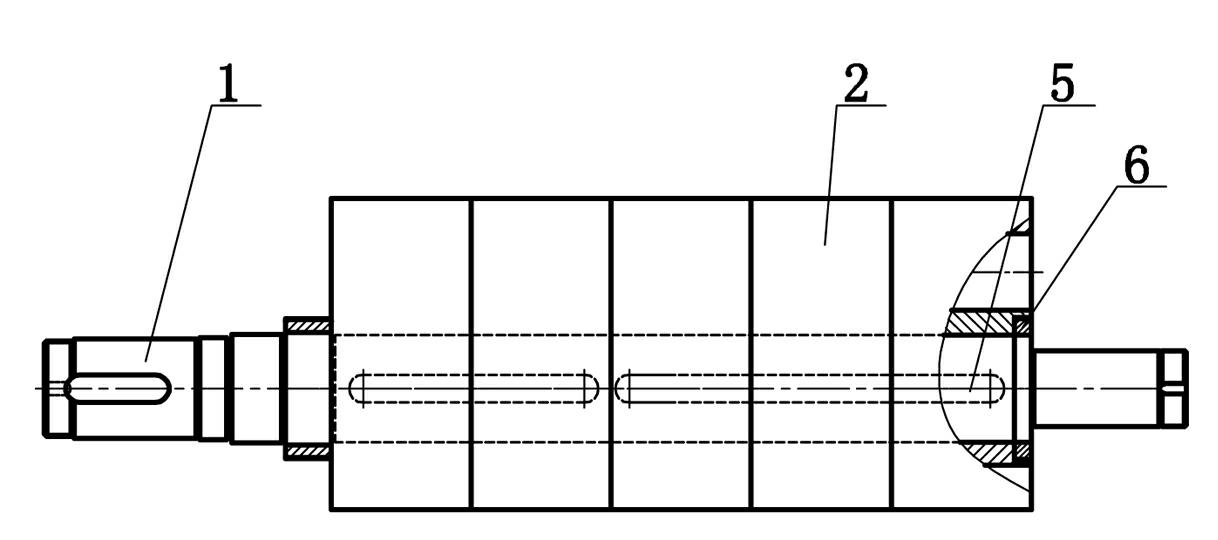

[0042] see figure 1 , the processing technology of the Roots blower impeller assembly. The impeller assembly is composed of a plurality of impeller blades 2 pressed by a special press, positioned and pressed with the positioning key 5, positioned and pressed on the impeller shaft 1, and then tightened by the lock nut 6. Specifically, Including the following process steps:

[0043] (1). The impeller shaft ( 1 ) is round steel blanking. After rough turning, it is quenched and tempered, and then it is fine turned, and the keyway and locking gasket groove are milled to meet the design requirements;

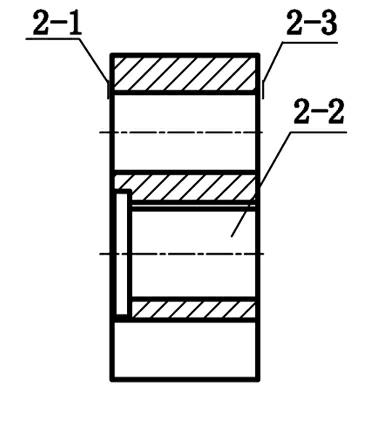

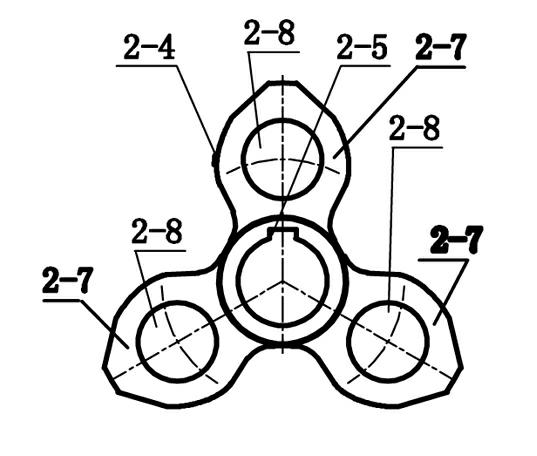

[0044] (2). Processing of impeller blade 2: see figure 2 , 3 ,

[0045] a. Cast the blank of the impeller blade 2 according to the figure and then perform annealing treatm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com