Preparing method of human body epidermis physiology electrode sensor

An electrode sensor and epidermis technology, applied in the direction of sensor, medical science, diagnosis, etc., can solve the problems of poor adaptability of flexible materials, harmful to human body and environment, small processing area, etc., to achieve good wearability and comfort, avoid Pollution, to achieve large-scale effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

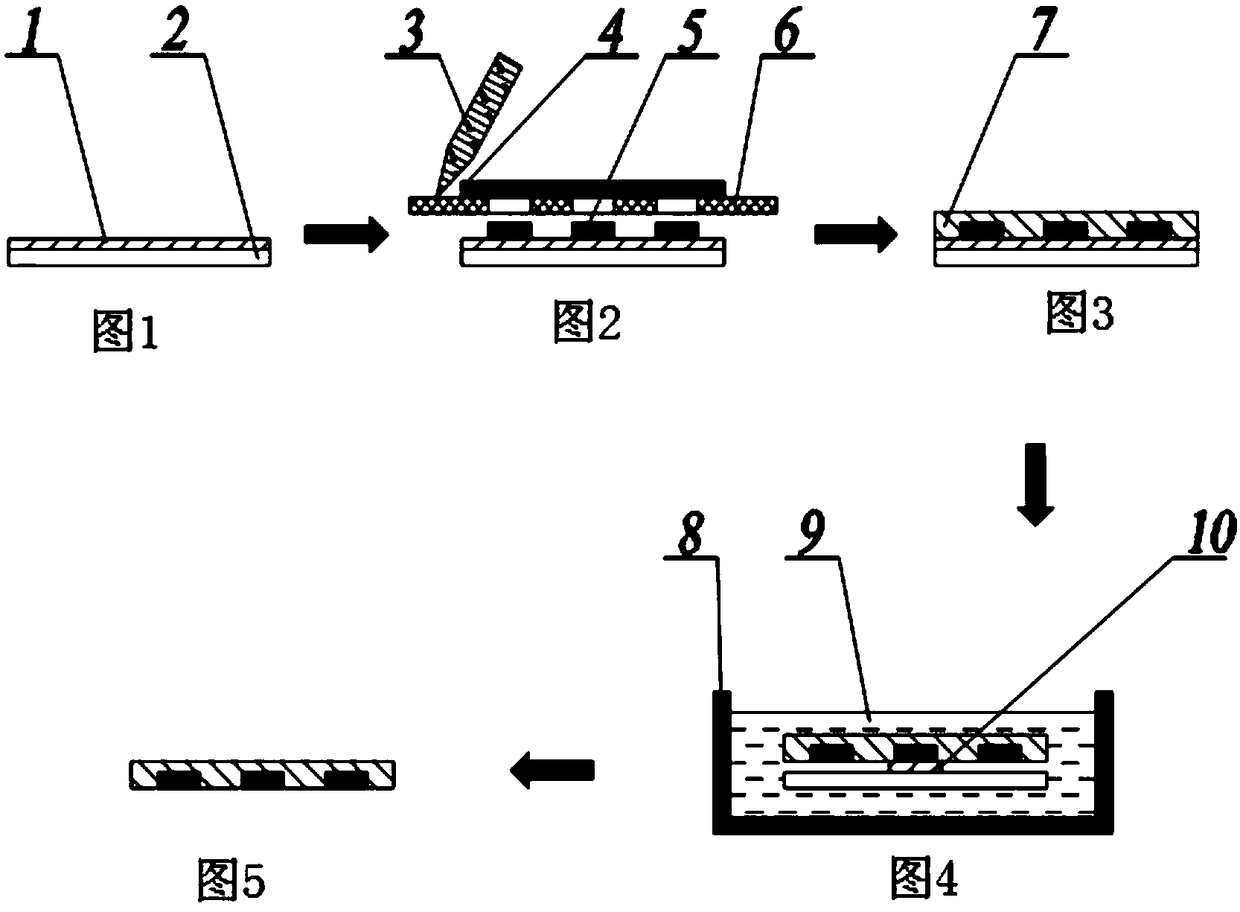

[0033] refer to Figure 1 to Figure 5 , the present invention provides a kind of preparation method of wearable human skin physiological electrode sensor, comprises the following steps:

[0034] (1) Clean the hard substrate 2 with acetone, isopropanol and deionized water in sequence, and then dry it with nitrogen. Preferably, the hard substrate 4 is a monocrystalline silicon wafer, polycrystalline silicon wafer, epitaxial wafer, quartz wafer or glass wafer, with a flat and smooth surface.

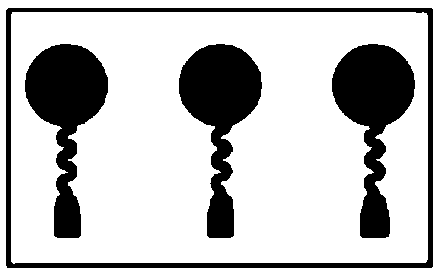

[0035] (2) Add polyvinyl alcohol powder into deionized water 9 to dissolve, configure polyvinyl alcohol solution, and let it stand for later use. Preferably, the mass fraction of polyvinyl alcohol in the polyvinyl alcohol aqueous solution is 8%-12%, and the mass fraction of the dispersant is 0.5%-2%. The dispersant used is sodium dodecylbenzenesulfonate or sodium dodecylsulfate. When preparing polyvinyl alcohol aqueous solution, add polyvinyl alcohol powder and dispersant to deionized water...

Embodiment 1

[0048] a. The hard substrate 2 is a 4-inch monocrystalline silicon wafer, and its polished surface is cleaned with acetone, isopropanol and deionized water in sequence and dried with nitrogen, and then the 10% concentration polyvinyl alcohol aqueous solution configured in the above scheme three is spin-coated On the above, the spin coating speed was 500 rpm and the spin coating time was 4 min. Afterwards, the silicon wafer was heated on a hot plate at a temperature of 80° C. for 15 minutes, so that the water was heated to evaporate, and the polyvinyl alcohol was solidified to form a film, and the preparation of the sacrificial layer 1 was completed.

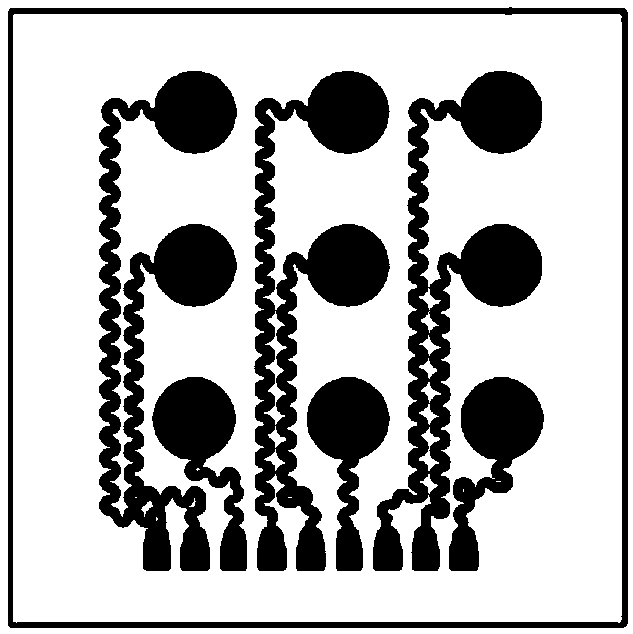

[0049] b. Put the hard substrate 2 on the stage of the manual screen printing machine, and keep the screen plate 6 parallel to the hard substrate 2 with a distance of 5 mm. After coating the pasty conductive material 4 on the 200 mesh screen plate 6, scrape the surface of the screen plate 6 with a scraper 3, the angle formed by t...

Embodiment 2

[0054] a. The selection of the hard substrate 2 and the preparation of the sacrificial layer 1 are the same as in Example 1.

[0055] b. Put the hard substrate 2 on the stage of the manual screen printing machine, and keep the screen plate 6 parallel to the hard substrate 2 with a distance of 8 mm. After the 300 mesh screen plate 6 is coated with paste-like conductive material 4, scrape the surface of the screen plate 6 with a scraper 3, the angle between the central axis of the scraper 3 and the forward direction during scraping is 60°, and the scraping speed is 5 cm / sec, a patterned functional layer 5 is formed. The hard substrate 2 is then heated to cure it. The thickness of the functional layer 5 is 40 micrometers.

[0056] c. Spin-coat platinum-catalyzed silicone rubber on the sacrificial layer 1 as the flexible substrate 7 of the human epidermal physiological electrode sensor. The spin-coating speed is 800 rpm, and the spin-coating time is 3 minutes, so that it covers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com