Parallel vibration pattern minitype electric field sensor

An electric field sensor and sensor technology, applied in the field of sensors, can solve the problems of high cost, limited detection range, and large volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

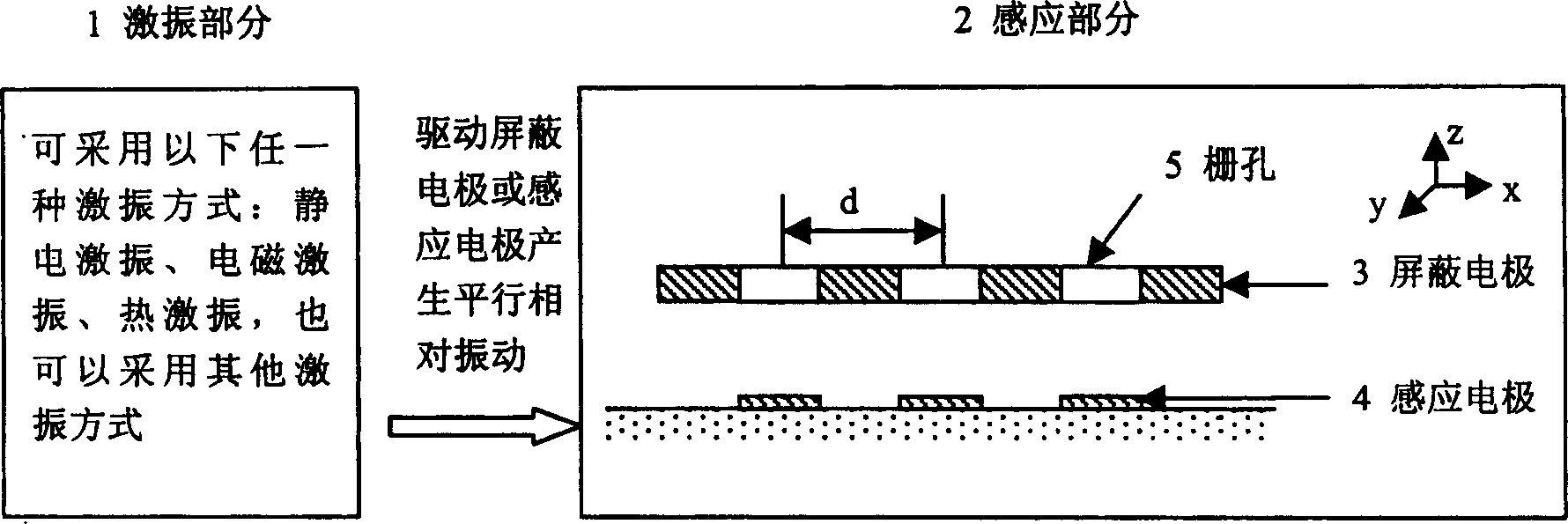

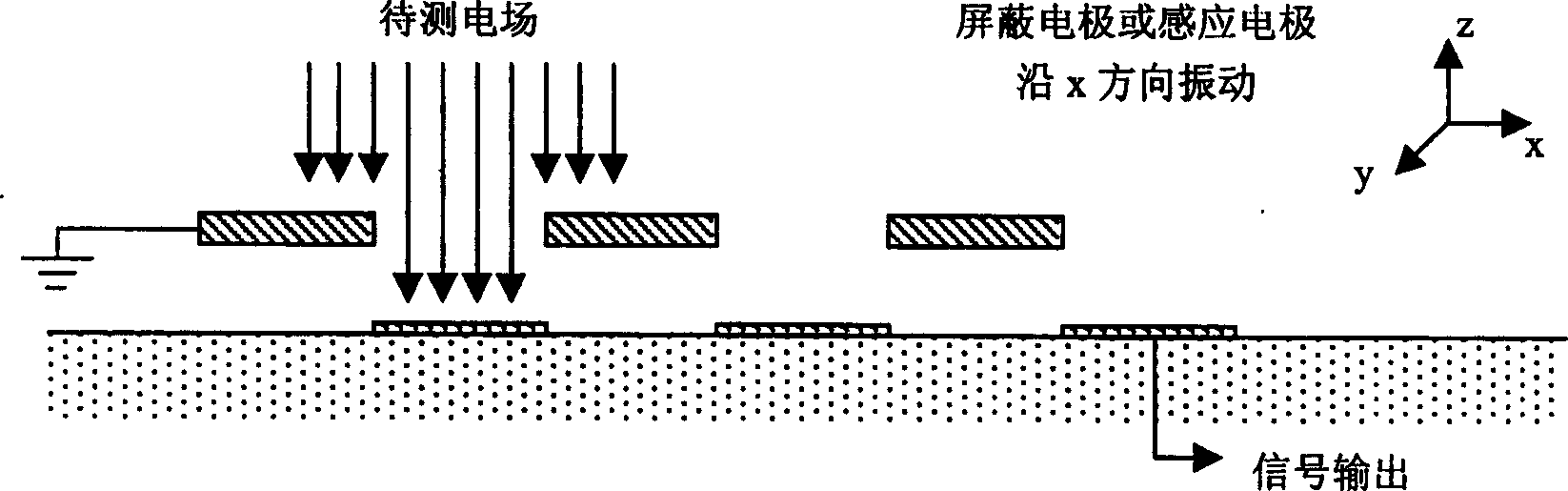

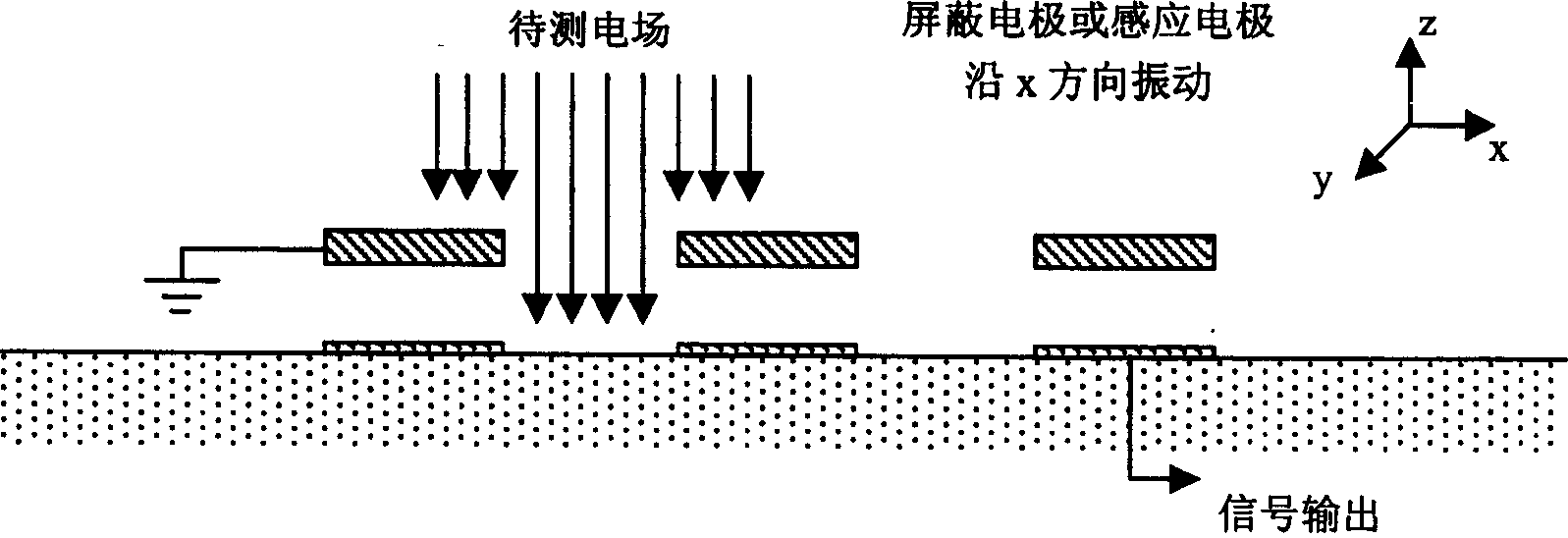

[0012] The structure of the parallel vibrating miniature electric field sensor is as follows: figure 1 As shown, it consists of two parts: excitation and induction. The sensing part is composed of the shielding electrode 3 and the sensing electrode 4 with a grid hole 5. The excitation part 1 generates a driving force, so that the shielding electrode 3 is parallel to the sensing electrode 4 to generate periodic relative motion, that is, the vibration direction is the x direction in Figure 2 (The vibration direction of the sensor described in the invention patent 02147377.3 is the z direction). The vibrating part can be the shielding electrode or the sensing electrode.

[0013] The shielding electrode 3 may be made of conductive material, or other materials coated with a conductive film, and has grid holes 5 on it. The shape of the grid hole 5 is rectangular, square, circular or other shapes, which are periodically distributed along the vibration direction; there may be multip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com