Surface treating method for improving TiAl base alloy surface property

A technology of surface treatment and surface properties, which is applied in the field of surface treatment to improve the surface properties of TiAl-based alloys, and can solve the problems of poor wear resistance and high-temperature oxidation resistance of TiAl-based alloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

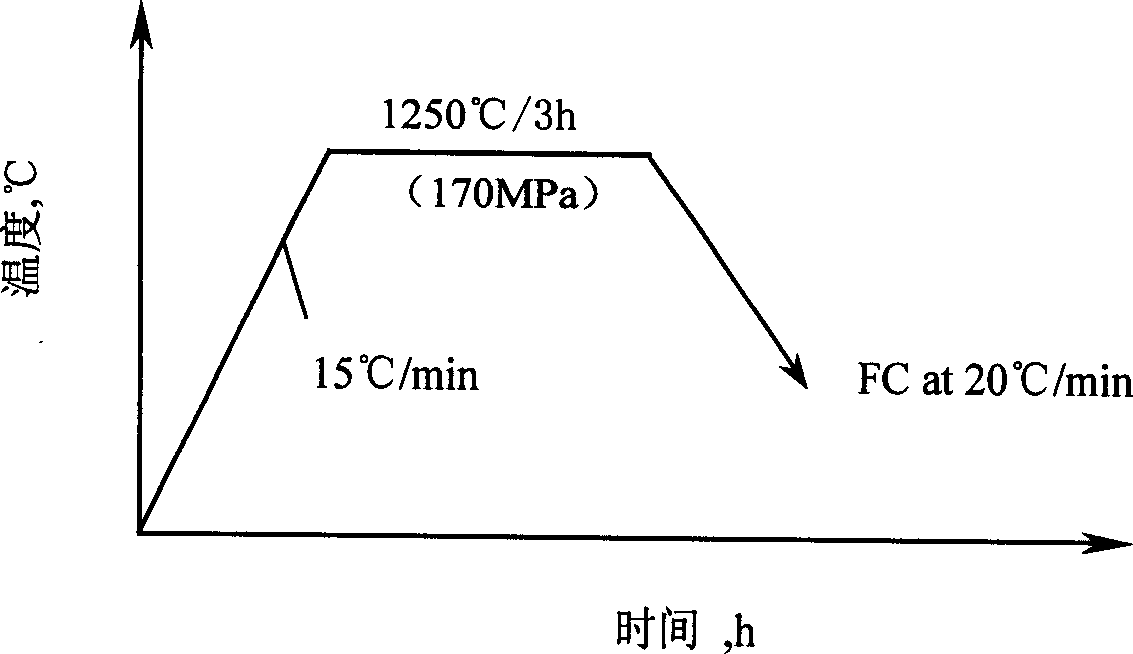

[0005] Embodiment 1: The method of this embodiment is: put the TiAl-based alloy containing high-content β-phase stable elements into the crucible of the hot isostatic pressing equipment with graphite or carbonaceous material as the heat source material or put it into the following Add 0.001 to 20000g of graphite powder and carbon Powder, carbon-containing elemental substances or carbon-containing compounds are subjected to hot isostatic pressing surface treatment. During the surface treatment process, argon or other inert gas is used as a protective gas, and argon is filled while heating up. After reaching the temperature and pressure of surface treatment, Carry out heat preservation, and after reaching the heat preservation time, it can be cooled to room temperature naturally with the crucible; the temperature of hot isostatic pressing surface treatment is 800-1500 ℃, the pressure of hot isostatic pressing surface treatment is 1-300MPa, the surface treatment of hot isostatic p...

specific Embodiment approach 2

[0006] Specific embodiment two: the difference between this embodiment and specific embodiment one is that in specific embodiment one, no graphite powder, carbon powder, Carbon-containing simple substance or carbon-containing compound, in order to better surface treatment in this embodiment, 0.0001-10000g of graphite powder, carbon powder, and Simple carbon or carbon-containing compounds are subjected to hot isostatic pressing surface treatment. Other methods are the same as in the first embodiment.

specific Embodiment approach 3

[0007] Specific embodiment three: the temperature of the hot isostatic pressing surface treatment in this embodiment is 810-1430°C, the pressure of the hot isostatic pressing surface treatment is 5-290MPa, and the holding time of the hot isostatic pressing surface treatment is 10 minutes to 19 Hour. Other methods are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com