Production process of automobile air cylinder cover

A production process and technology of cylinder head, which is applied in the field of production process of automobile cylinder head, can solve problems such as deformation and affecting the sealing effect of cylinder head, and achieve the effect of simple and direct process, good practicability and convenient batch processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

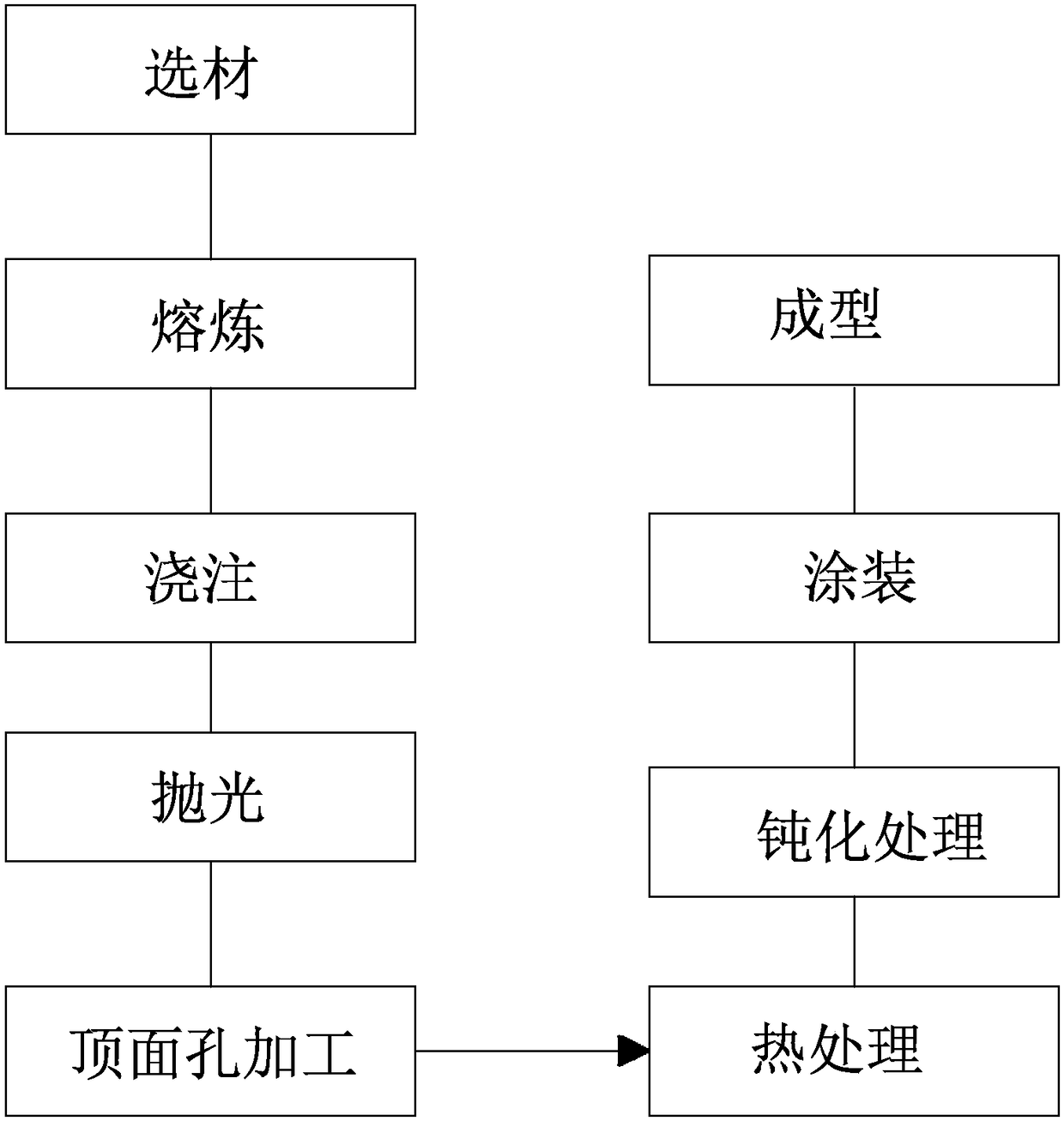

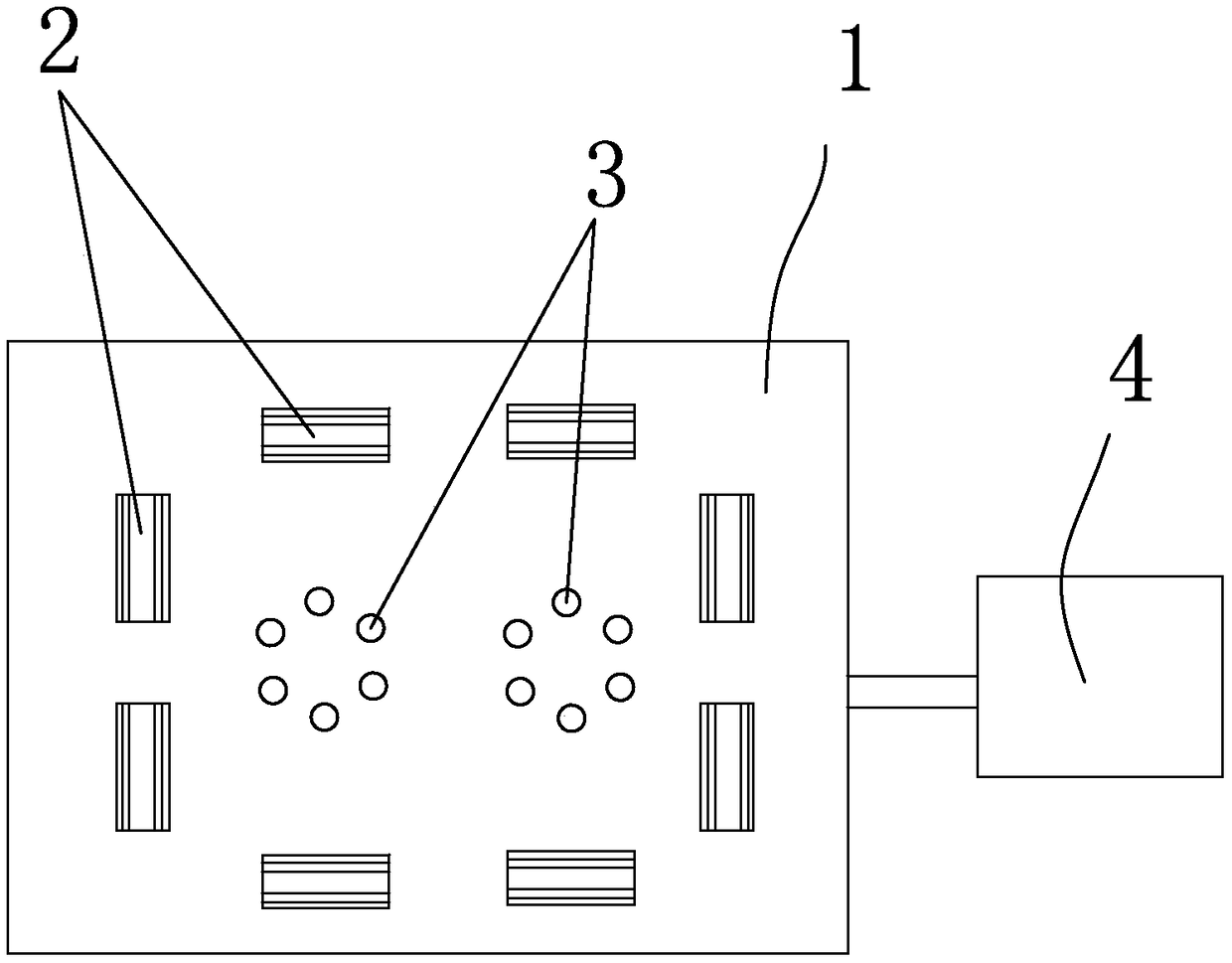

[0026] refer to Figure 1 to Figure 4 A production process example of an automobile cylinder head of the present invention will be further described.

[0027] A production process of a cylinder head for automobiles, comprising the following steps: (1) Material selection: each chemical composition (%) of raw materials: Fe≤1.3, Si: 9.6-12, Cu: 1.5-3.5, Mn≤0.5, Mg≤ 0.3, Ni≤0.5, Zn≤3.0, Pb≤0.2, Sn≤0.2, the rest is Al;

[0028] (2) Smelting: Melt the raw materials in step (1) to about 800-850°C, refine the raw materials through GBF treatment, degas and remove slag, and transfer the refined and degassed aluminum liquid after standing for 10 minutes Go to the protective furnace of the low pressure casting machine, and control the molten aluminum to be poured between 690°C and 700°C;

[0029] (3) Pouring: The pouring liquid formed by the raw materials passes through the molten iron channel from the sprue cup to the cavity, and the temperature during pouring is controlled between 690...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com