Pretreatment device for aquatic product before salting

A pretreatment device and technology for aquatic products, applied in the direction of fish workbench, arranging fish, slaughtering, etc., can solve the problems of unfavorable batch processing and low efficiency, and achieve increased surface contact area, simple structure, and convenient pickling processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

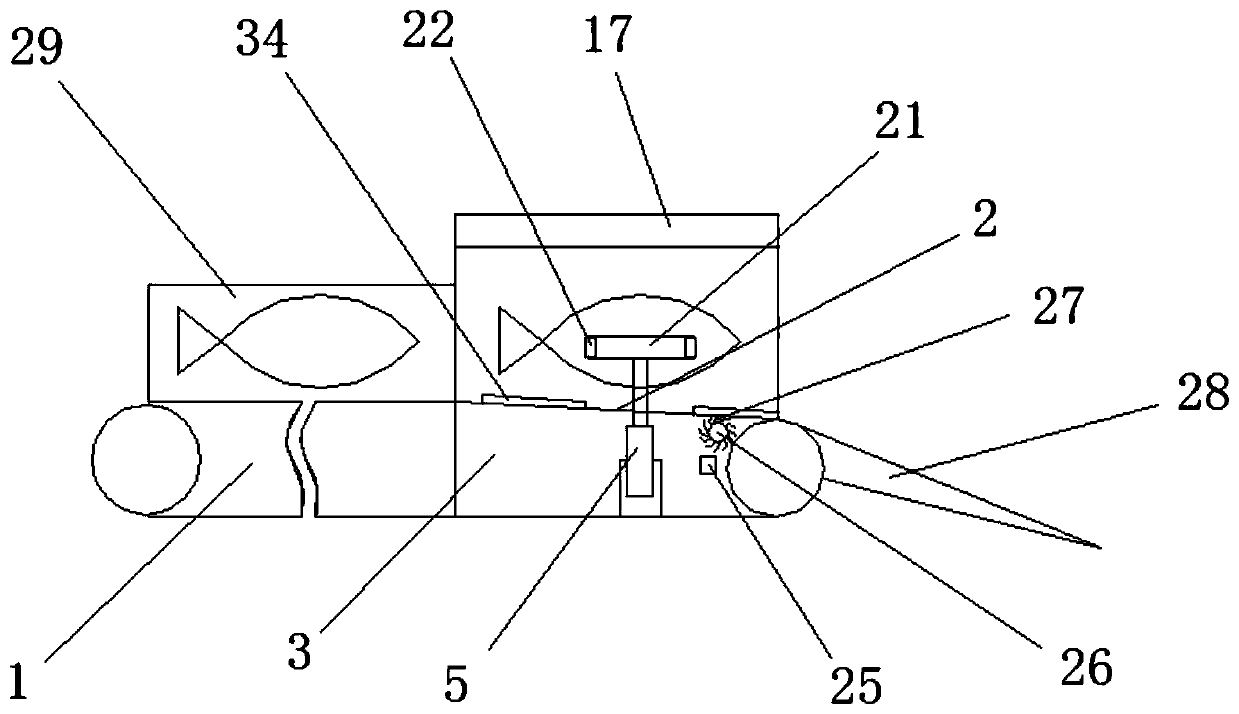

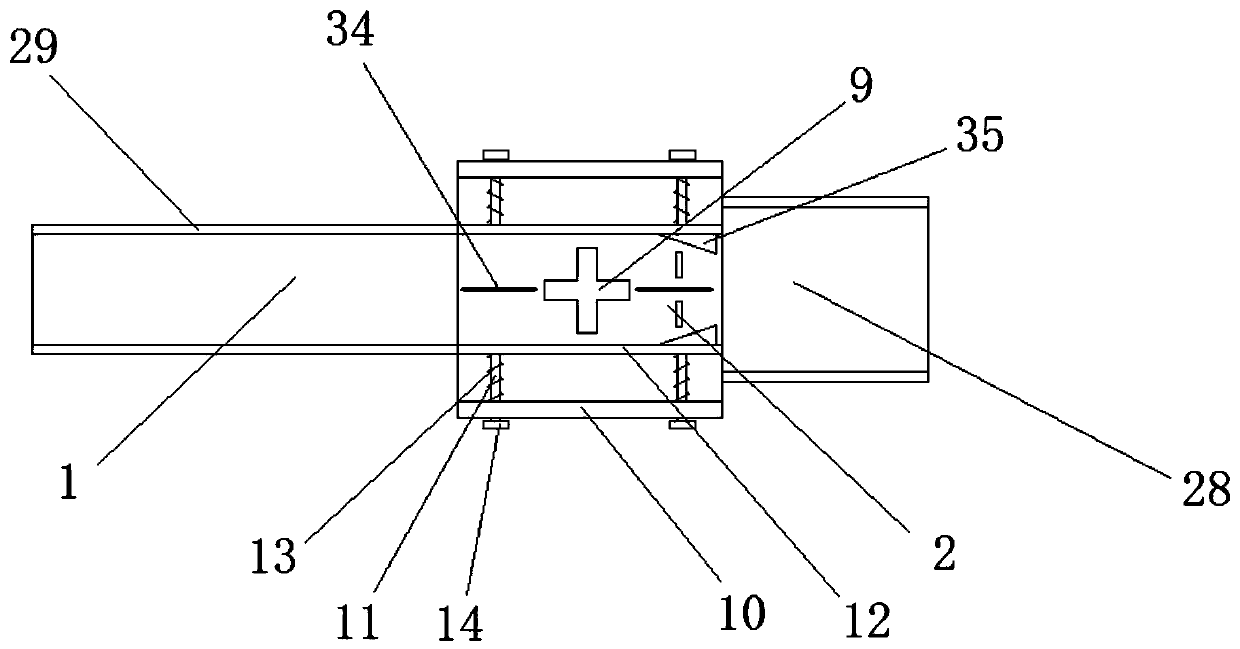

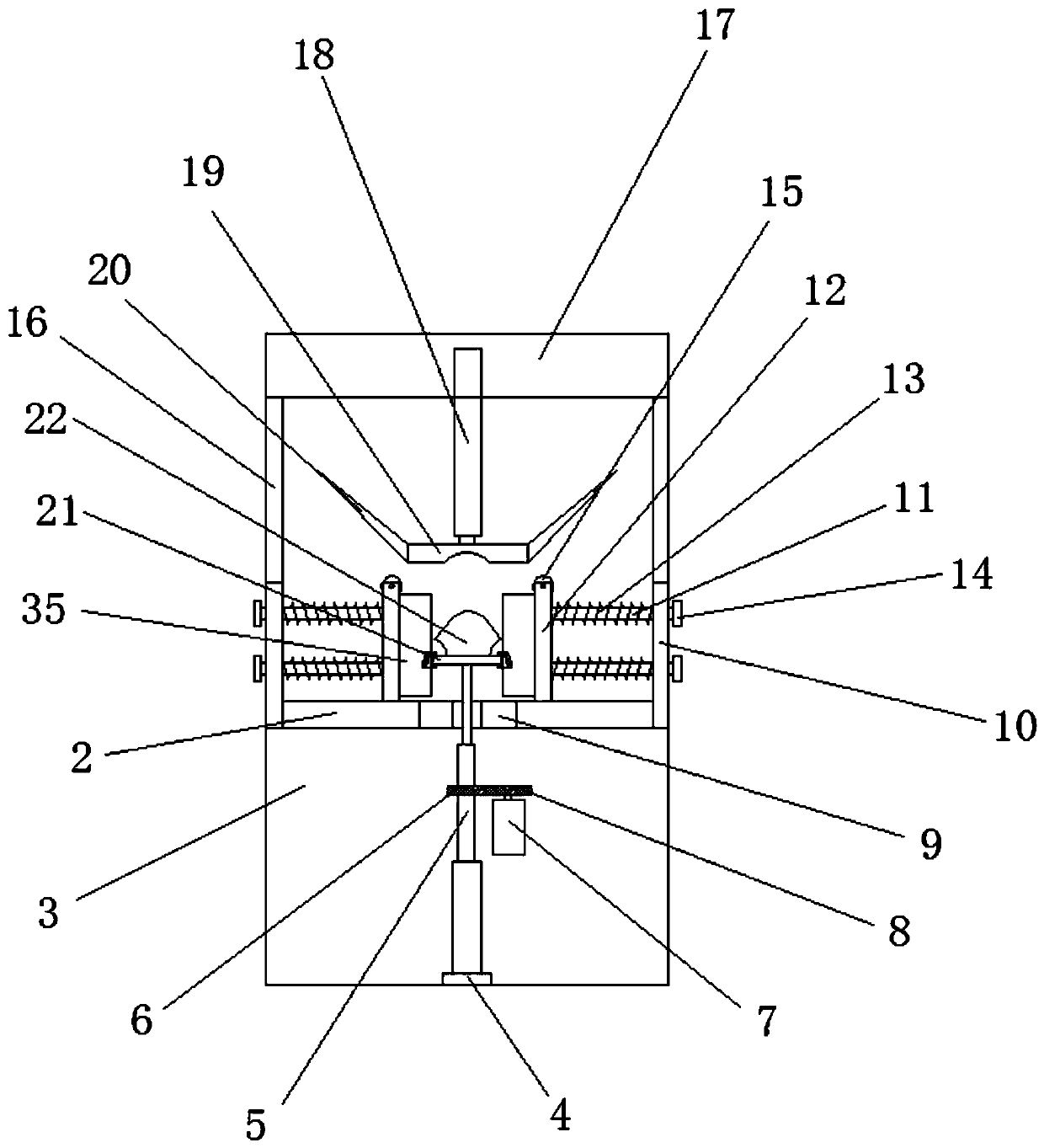

[0031] Embodiment 1: as Figure 1-5 As shown, a pre-treatment device for pickling aquatic products includes a conveyor belt 1 and a processing table 2, and the processing table 2 is located on the right side of the conveyor belt 1;

[0032] The fish after opening will be transported to the processing table with the head facing forward through the conveyor belt.

[0033] The bottom of the processing table 2 is fixedly installed with a bottom bin 3, and the bottom of the inner cavity of the bottom bin 3 is fixedly installed with a bearing 4, and the top of the bearing 4 is rotatably connected with a telescopic rod 5, and the telescopic rod 5 is equipped with a The second spring 24, the telescopic rod can shrink under the effect of external force, and recover after the external force is canceled.

[0034] The top of the processing table 2 is provided with a cross-shaped groove 9, and the top of the telescopic rod 5 is fixedly connected with a stay 21 through the cross-shaped gro...

Embodiment 2

[0047] Embodiment 2: as Figure 1-5 As shown, a pre-treatment device for pickling aquatic products includes a conveyor belt 1 and a processing table 2, and the processing table 2 is located on the right side of the conveyor belt 1;

[0048] The fish after opening will be transported to the processing table with the head facing forward through the conveyor belt.

[0049] The bottom of the processing table 2 is fixedly installed with a bottom bin 3, and the bottom of the inner cavity of the bottom bin 3 is fixedly installed with a bearing 4, and the top of the bearing 4 is rotatably connected with a telescopic rod 5, and the upper end of the telescopic rod 5 is socketed There is a support rod, and the second spring 24 is installed inside it, and the telescopic rod can shrink under the effect of external force, and restore after the external force is canceled.

[0050] The top of the processing table 2 is provided with a cross-shaped groove 9, and the top of the telescopic rod 5...

Embodiment 3

[0065] Embodiment 3: as Figure 1-6 As shown, a pre-treatment device for pickling aquatic products includes a conveyor belt 1 and a processing table 2, and the processing table 2 is located on the right side of the conveyor belt 1;

[0066] The fish after opening will be transported to the processing table with the head facing forward through the conveyor belt.

[0067] The bottom of the processing table 2 is fixedly installed with a bottom bin 3, and the bottom of the inner cavity of the bottom bin 3 is fixedly installed with a bearing 4, and the top of the bearing 4 is rotatably connected with a telescopic rod 5, and the upper end of the telescopic rod 5 is socketed There is a support rod, and the second spring 24 is installed inside it, and the telescopic rod can shrink under the effect of external force, and restore after the external force is canceled.

[0068] The top of the processing table 2 is provided with a cross-shaped groove 9, and the top of the telescopic rod 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com