Method for manufacturing minitype liquid methanol fuel cell

A technology of methanol fuel cell and manufacturing method, which is applied to fuel cell parts, fuel cells, aqueous electrolyte fuel cells, etc., can solve the problems of reducing the physical size of the battery, achieve low manufacturing cost, increase structural strength, and be easy to design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

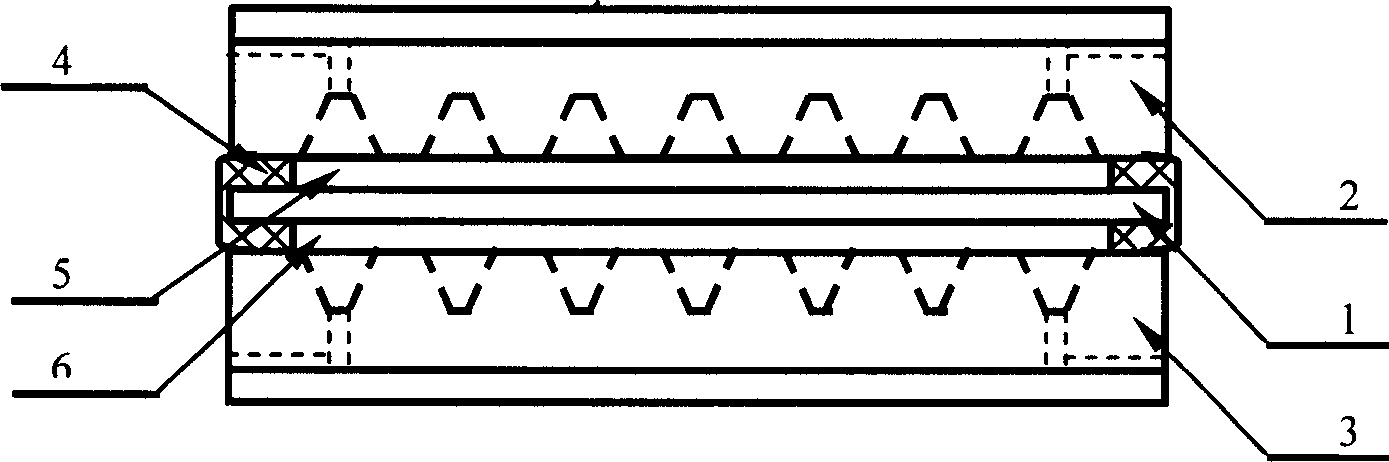

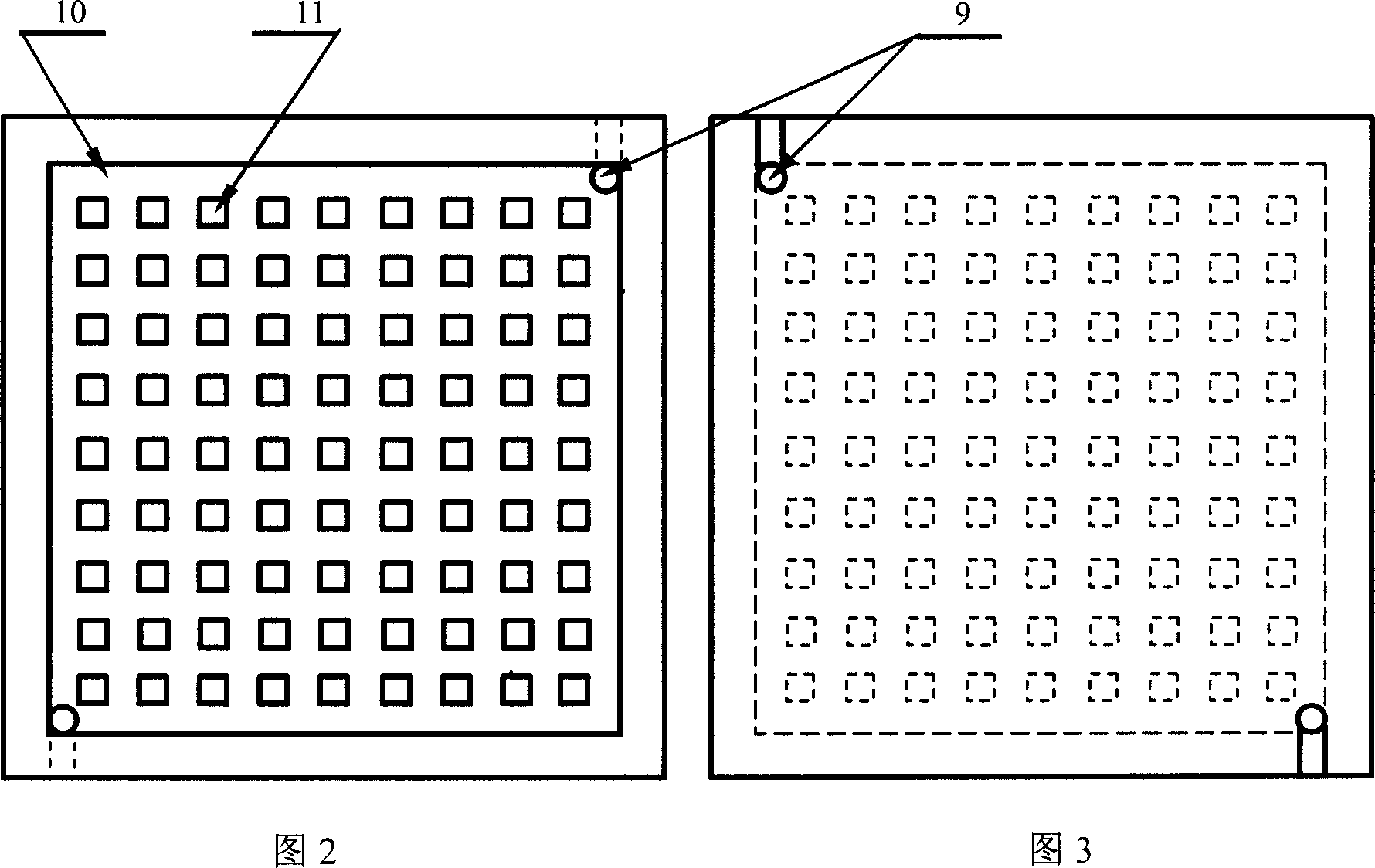

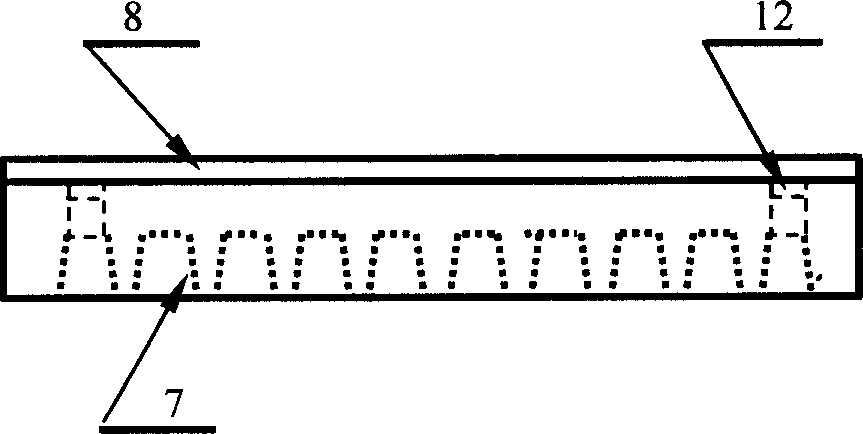

[0018] Example 1: Combining figure 1 As shown in Fig. 2, the composition of the micro liquid methanol fuel cell includes a membrane electrode 1 and bipolar plates 2, 3 positioned on both sides of the membrane electrode. Resin glue4. Bipolar plates are made from silicon wafers. The silicon wafer was ultrasonically cleaned with toluene, acetone and ethanol respectively. The cleaned silicon wafers are placed in an oxidation furnace, and the temperature of the oxidation furnace is controlled at 1180°C. The temperature of the water bath is 95-97°C, and the oxygen flow rate is 1l / min. layer of silicon dioxide. The photolithographic method is used to carve the pattern of the flow chamber and the oxide layer of the liquid diversion channel, and the support points 11 in the flow chamber may be distributed in a point form or in a serpentine form. Then use HF acid to etch the silicon dioxide to open the window for etching the silicon body. The silicon body is etched with a KOH solu...

Embodiment 2

[0019] Embodiment 2: Combination figure 1 As shown in Fig. 2, the composition of the micro liquid methanol fuel cell includes a membrane electrode 1 and bipolar plates 2, 3 positioned on both sides of the membrane electrode. Resin glue4. A bipolar plate is made from a silicon wafer with a thickness of 10mm×10mm and a thickness of 500 microns. The silicon wafer was ultrasonically cleaned with toluene, acetone and ethanol respectively. The cleaned silicon wafers are placed in an oxidation furnace, and the temperature of the oxidation furnace is controlled at 1180°C. The temperature of the water bath is 97°C, and the oxygen flow rate is 1l / min. Floor. The photolithographic method is used to engrave the pattern of the flow chamber and the oxide layer of the liquid channel. The support points in the flow chamber can be distributed in a point-like manner. The support points are 0.4mm×0.4mm, and the distance between the support points is also 0.4mm. Then use HF acid to etch the ...

Embodiment 3

[0020] Embodiment 3: Serpentine flow field structure. Change the graphic design of the lithography mask. A photolithographic mask with a serpentine structure is selected, and other process steps are the same as those in Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com