Casting machining device

A processing device and casting technology, which is applied in the field of casting processing and manufacturing, can solve the problems of manual scratch safety, hidden dangers, and easy splashing of waste chips on human hands, etc., and achieve the effect of facilitating batch processing and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below by means of specific embodiments:

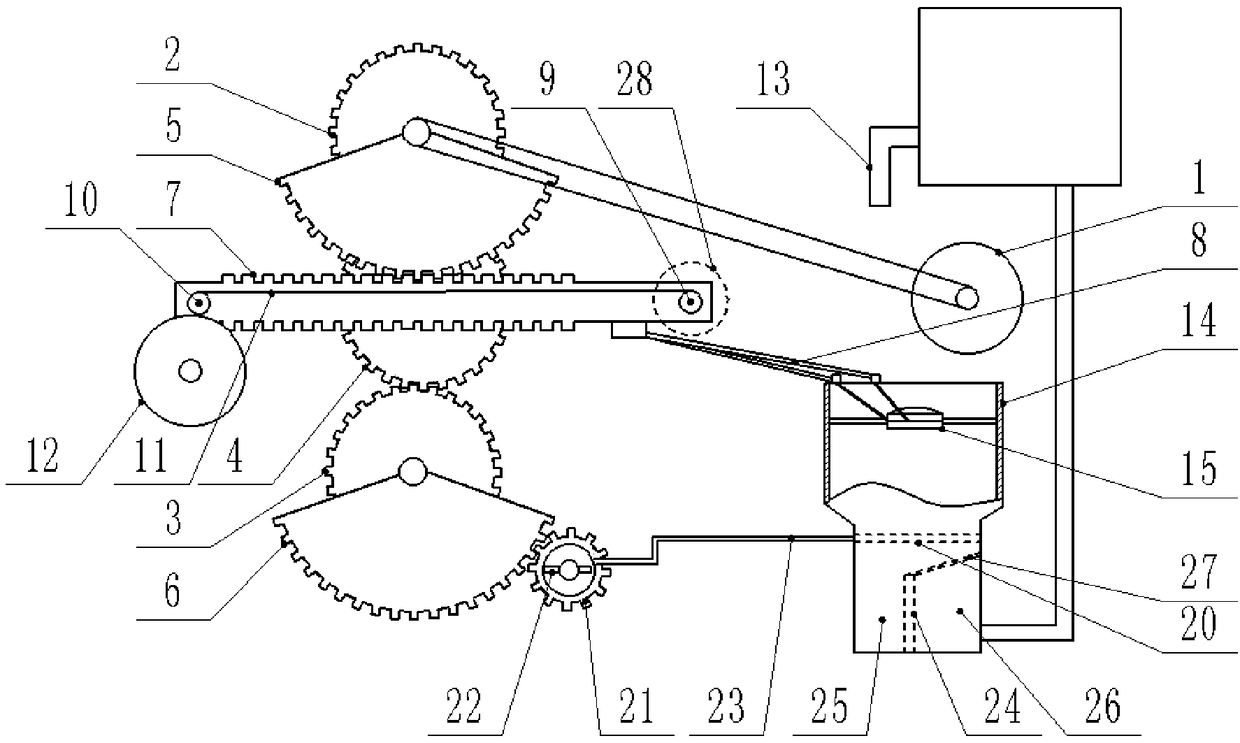

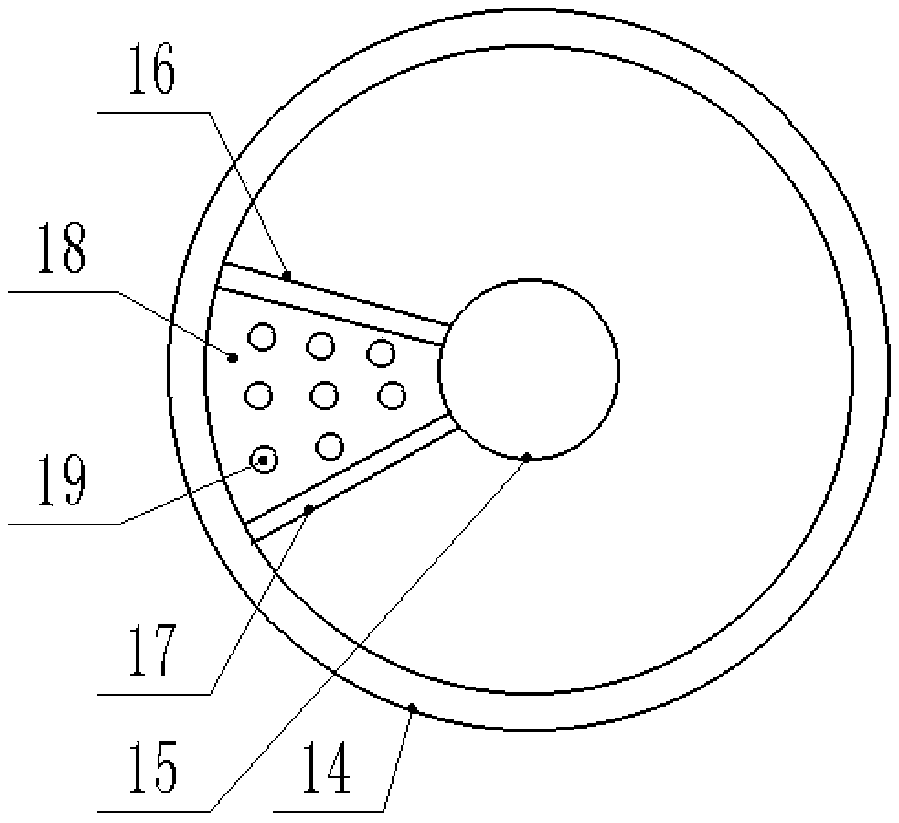

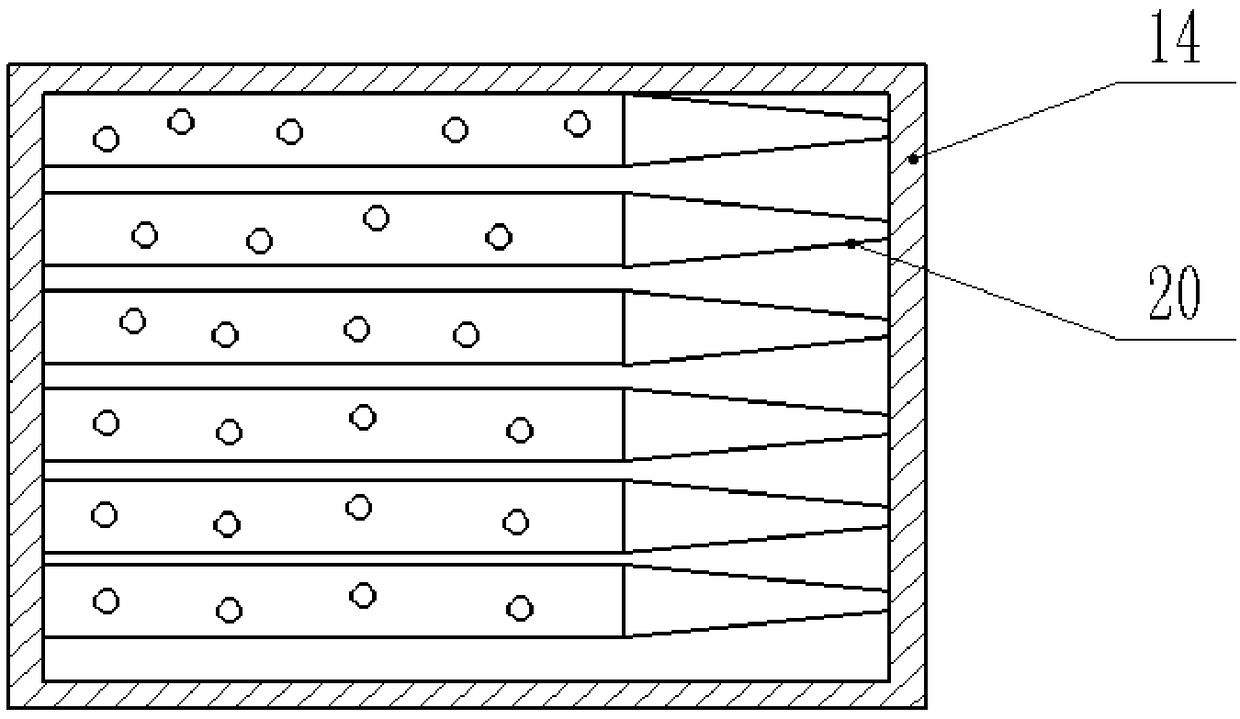

[0019] The reference signs in the drawings of the description include: grinding wheel 1, transmission gear 2, return gear 3, connecting gear 4, transmission fan gear 5, return fan gear 6, rack 7, push rod 8, pay-off wheel 9, winding Wire wheel 10, pull cord 11, friction wheel 12, water pipe 13, drainage groove 14, round table 15, first connecting rod 16, second connecting rod 17, elastic cloth 18, filter hole 19, hose 20, spur gear 21, Fan blade 22, air duct 23, vertical plate 24, slag storage chamber 25, drainage chamber 26, filter screen 27, casting 28.

[0020] Example figure 1 Shown: a processing device for castings, including a grinding wheel 1 and a transmission mechanism, the transmission mechanism includes a transmission gear 2 and a return gear 3 that are both rotatable, and a connecting gear 4 is provided between the transmission gear 2 and the return gear 3, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com