Full-automatic correction system for acceleration sensor

A technology of acceleration sensor and correction system, which is applied in the testing/calibration of speed/acceleration/shock measurement equipment, speed/acceleration/shock measurement, instruments, etc., which can solve the problem of inability to realize batch operation, cumbersome manual correction procedures, and affecting sensors Measured values and other issues, to achieve the effect of easy batch processing, rapid acquisition, and improved measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

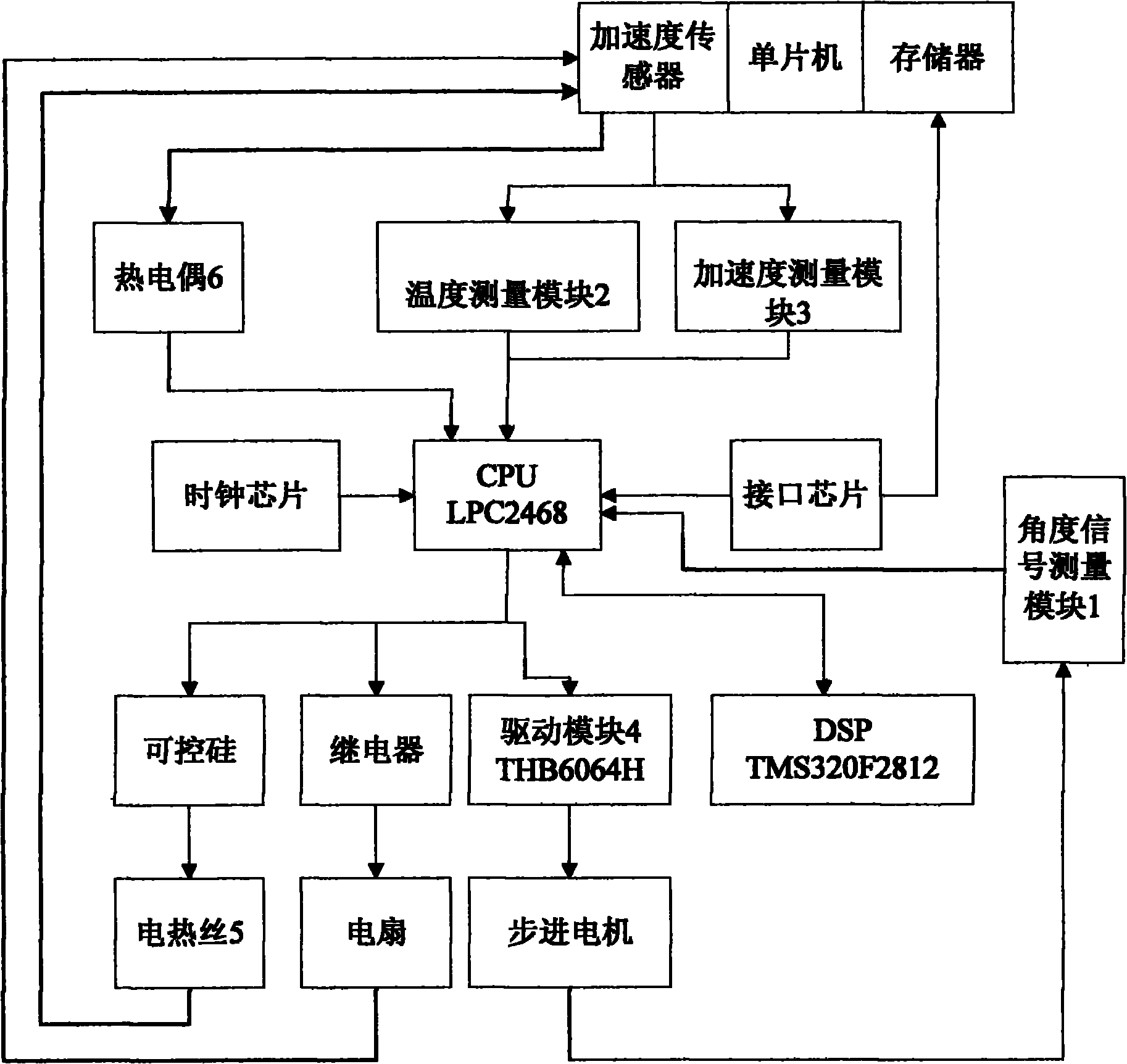

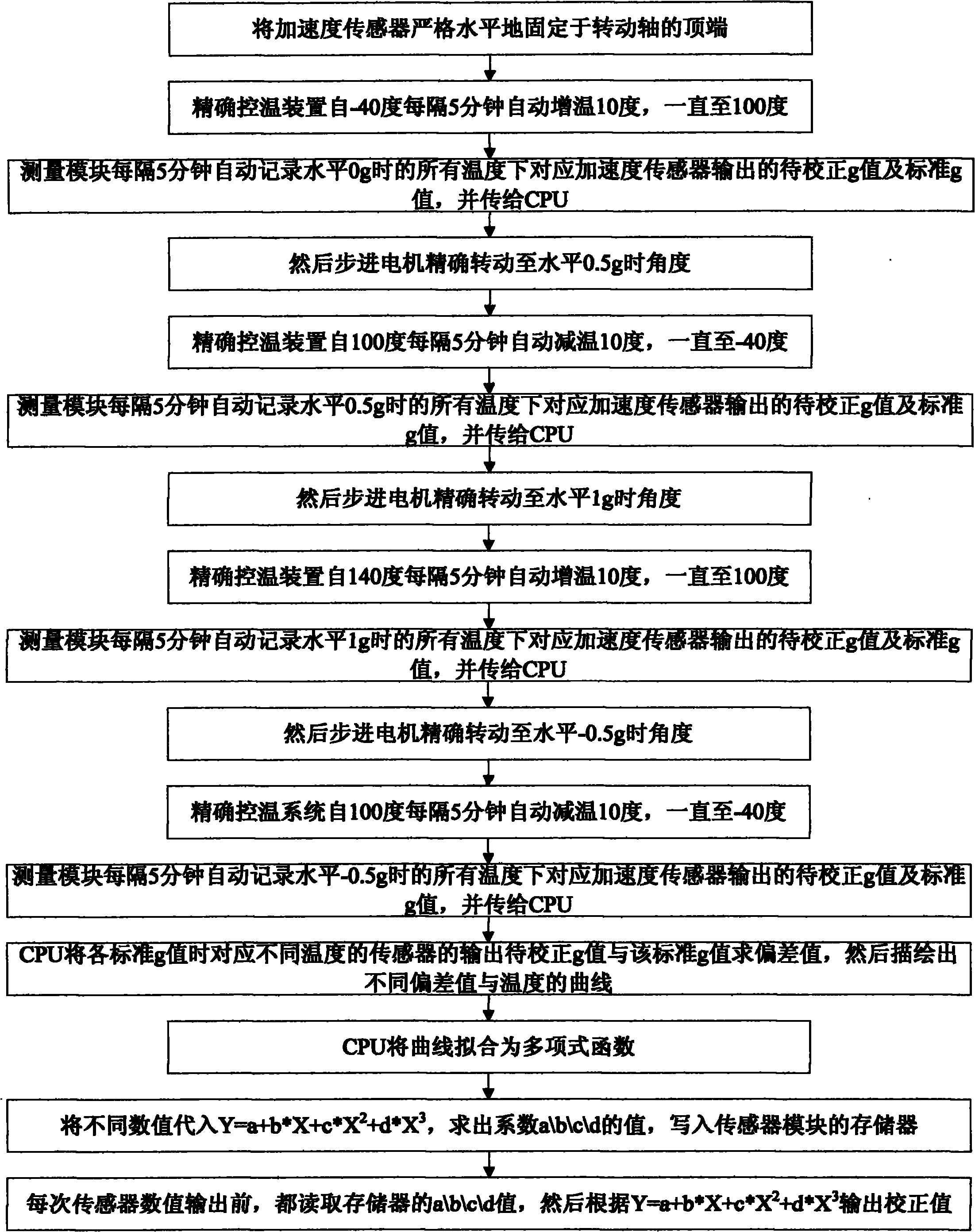

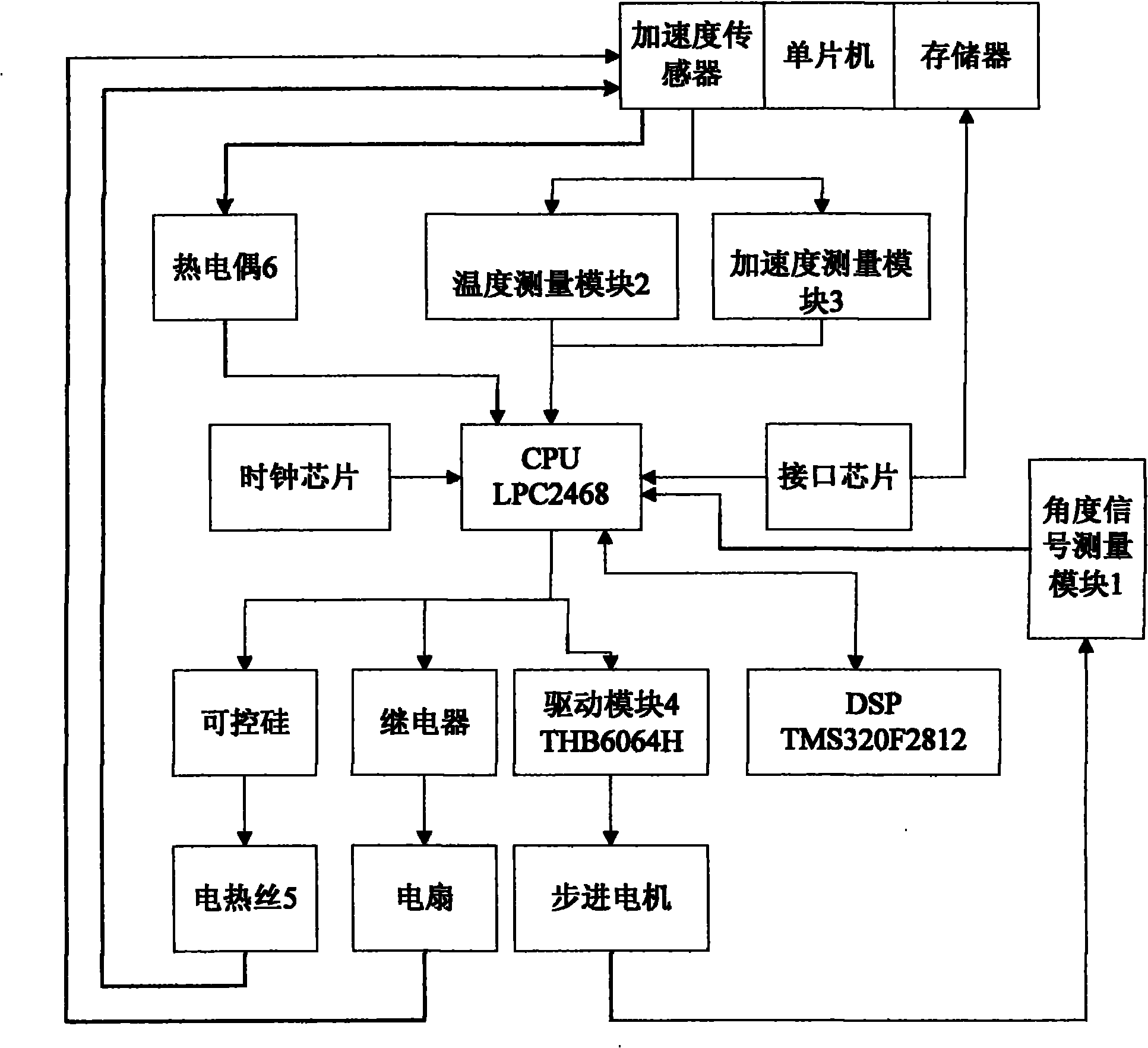

[0017] Such as figure 1 As shown, a fully automatic calibration system for an acceleration sensor includes:

[0018] A precise temperature control device for heating or cooling the acceleration sensor fixed on the drive shaft of the stepping motor;

[0019] Measure the angle signal measurement module 1 of the standard g value of the stepper motor;

[0020] A temperature measurement module 2 for measuring the temperature of the acceleration sensor;

[0021] An acceleration measurement module 3 for measuring the g value to be corrected under different temperatures of the acceleration sensor;

[0022] A drive module 4 that drives the stepper motor to rotate;

[0023] And the CPU connected to the precise temperature control device, the angle signal measurement module 1, the temperature measurement module 2, the acceleration measurement module 3, and the drive module 4;

[0024] The CPU calculates the deviation value between the g value to be corrected and the standard g value ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com