Processing fixture for elastic buckle

A technology of fixing devices and elastic buckles, which is applied to workpiece clamping devices, manufacturing tools, signal transmission systems, etc., can solve problems such as low work efficiency, low degree of automation, and high risk factor, and achieve improved work efficiency and high degree of automation , the effect of reasonable design layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

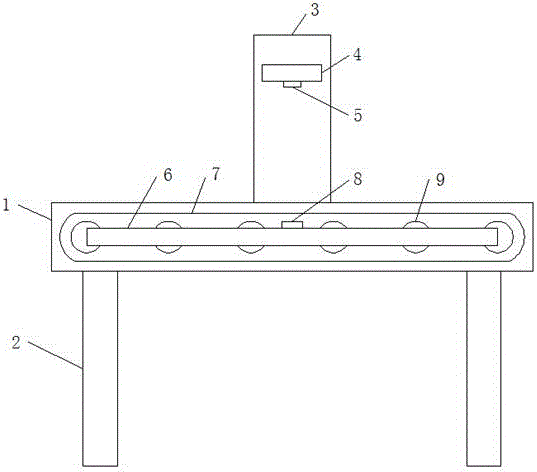

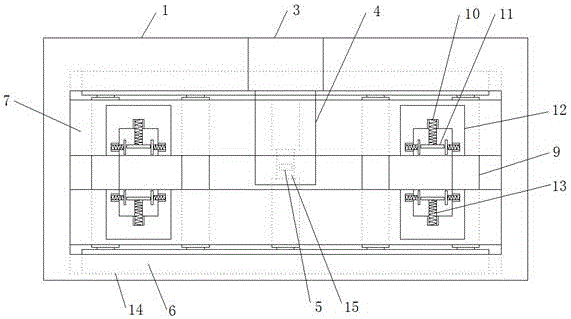

[0017] refer to Figure 1-2 , a processing and fixing device for elastic buckles, comprising a workbench 1, legs 2 are provided on both sides of the bottom end of the workbench 1, an opening and a vertical support plate 3 are arranged on the top of the workbench 1, and the support plate 3 is located on one side of the opening, and the side of the support plate 3 close to the workbench 1 is provided with a horizontal installation plate 4, the bottom of the installation plate 4 is embedded with an infrared transmitter 5, and the workbench 1 is also provided with a card slot 14 , the card slot 14 communicates with the opening, the card slot 14 is provided with a rotating motor, the inner wall of the card slot 14 is fixedly installed with a connecting plate 6, and a connecting rod 15 is connected between the connecting plates 6, and the top of the connecting rod 15 is embedded with an infrared ray Receiver 8, infrared receiver 8 is corresponding with infrared emitter 5, and the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com