An intelligent oil edge production line and its production process

A production process and production line technology, which is applied in the field of intelligent oil edge production line and its production process, can solve the problems of increased defective product rate, high labor cost and time cost of oil edge process, wrong oil edge frequency and other problems, and achieves the reduction of products The effect of defective rate, saving manpower and floor area, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

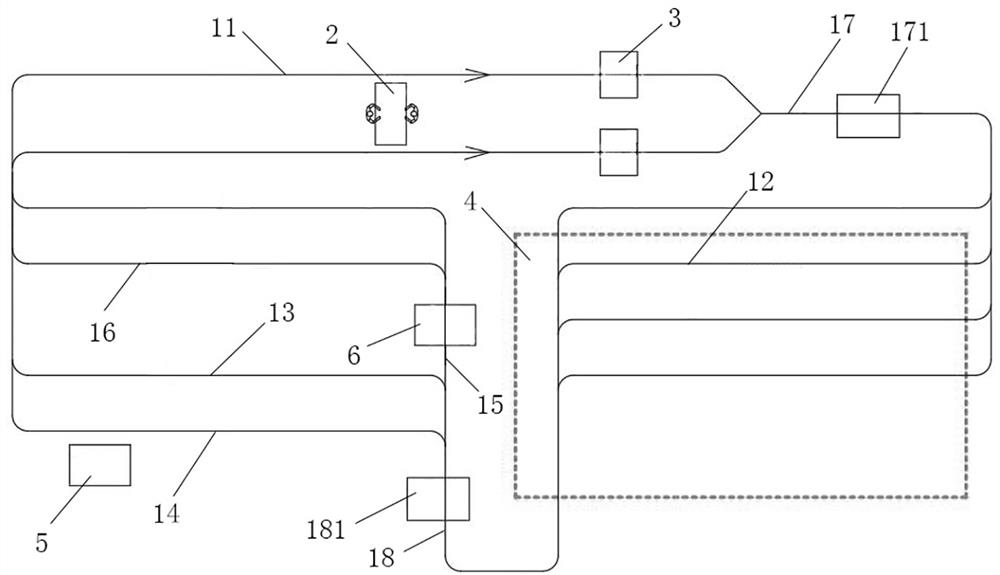

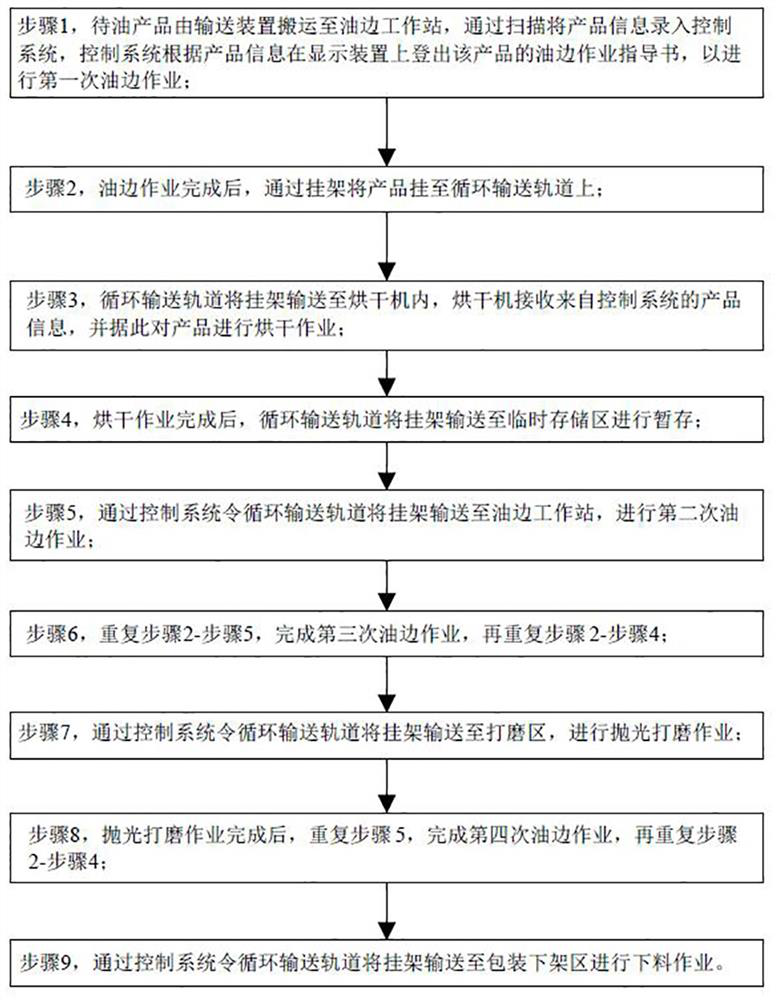

[0065] Such as figure 1 As shown, an intelligent oil edge production line includes a control system, a circulating conveying track, an oil edge workstation 2 arranged along the circulating conveying track, a dryer 3, a temporary storage area 4, a grinding area 5, and a packaging and unloading area 6. Specifically, the circulation conveying track includes an oil side track 11, a storage track 12, and a circulation channel 13, the oil side workstation 2 is arranged on the side of the oil side track 11, the storage track 12 constitutes the temporary storage area 4, and the Circulation channel 13 is connected with grinding track 14 in parallel, and described grinding area 5 is arranged on the side of grinding track 14, and the rail entry end of described circulation channel 13 is connected with lower shelf track 15, and described packaging lower shelf area 6 is arranged at lower shelf At the track 15 , the derailed end of the underframe track 15 is connected to an empty car tempo...

Embodiment 2

[0070] The difference from Example 1 is that no dryer is installed on the oil edge track, and the products after oil edge are directly transported to the temporary storage area, and only the temporary storage area is used to dry the products naturally, which can be applied to the failure of the dryer maintenance etc.

Embodiment 3

[0072] The difference from Example 1 is that there is no temporary storage area on the production line, and the products dried by the dryer are directly transported to the circulation channel 13 or the grinding track 14 or the off-shelf track 15, which can be applied to products with a small amount of processing and so on.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com