Gauge regulator for ballastless tracks

A ballastless track and adjuster technology, which is applied in the direction of track, track maintenance, road, etc., can solve the problem of difficult to realize long-distance high-speed rail line inspection and maintenance, unable to realize continuous adjustment of rail deviation points, and high labor intensity of adjustment workers. problem, to achieve the effect of frequent reversing, easy overload protection and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

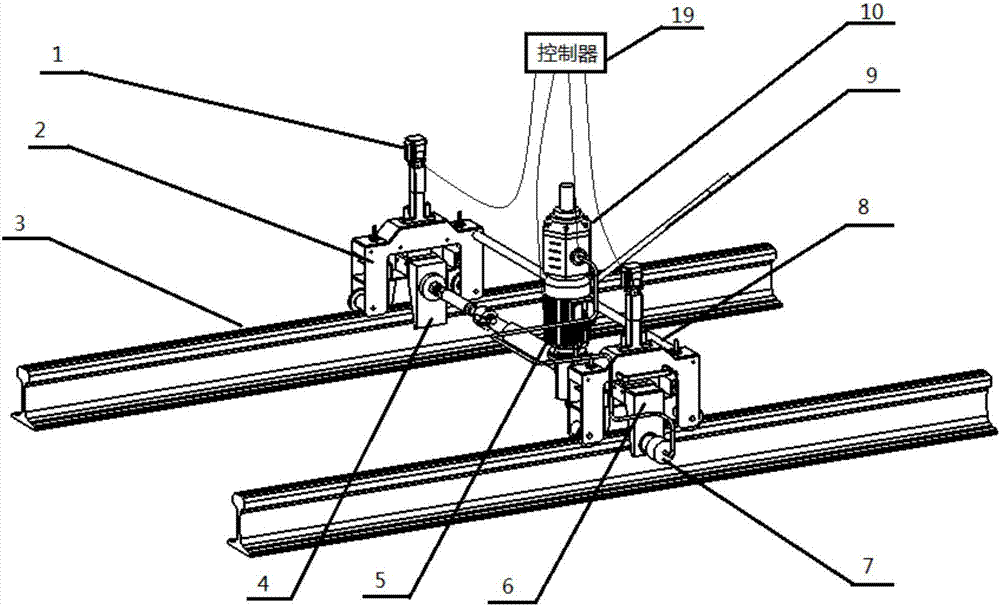

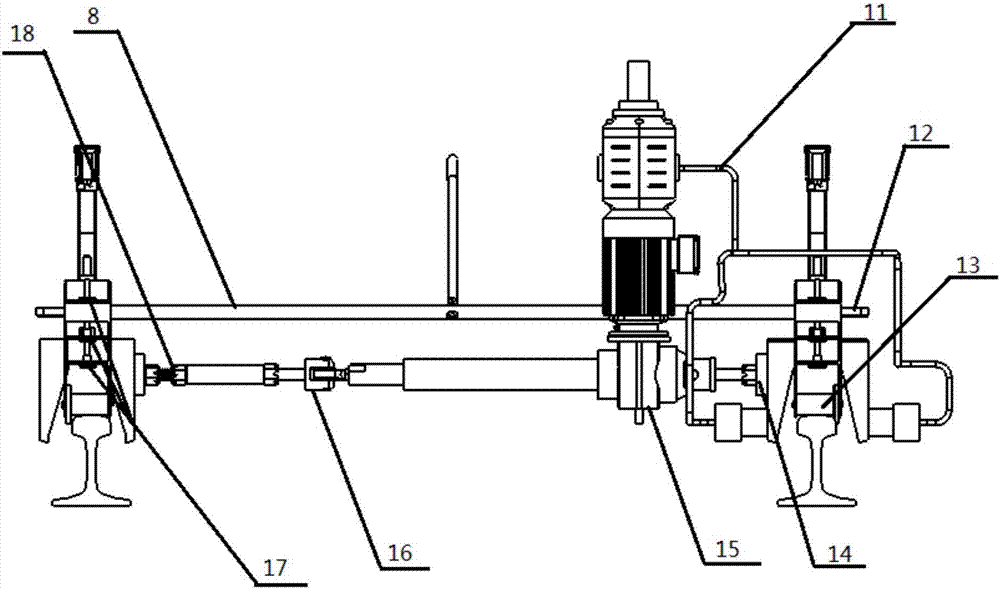

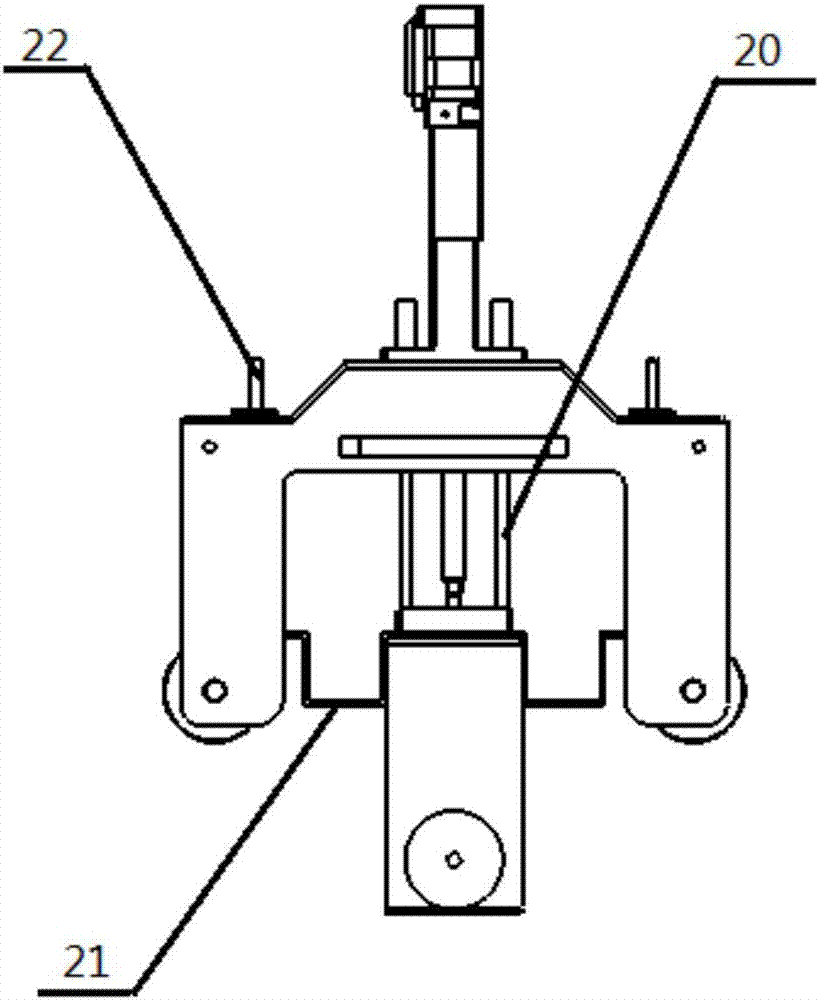

[0032] A ballastless track gauge adjuster, its structure is as follows Figure 1-2 As shown, it includes a controller 19, an electromagnet 1 for adjusting the lifting position, a guide piston rod 20 for limiting the direction of movement, a reference rail clamp 4 for a fixed rail and a movable rail clamp 6 to control the automatic clamping and opening of the above-mentioned track clamps. The hydraulic system is connected to the gauge adjustment mechanism between the reference rail track clamp 4 and the movable rail track clamp 6.

[0033] This ballastless gauge adjuster realizes the automation of gauge adjustment from three actions. The controller 19 controls the electromagnet 1 to energize, so that the guide piston rod 20 is forced to move downward. Under the restriction, ensure that the track adjuster can only move up and down directly above the rail 3. When the track car guide bar 22 and the track car 2 are assembled, the assembly accuracy and strength are guaranteed by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com