Device and method for achieving reciprocating motion of fracturing pump through rotation of lead screw nut

A reciprocating motion, fracturing pump technology, applied in the direction of transmission, pumping device components for elastic fluid, pump components, etc., can solve the problems of impact at both ends of the raceway, thrust reduction, and ball screw life reduction , to achieve the effect of reducing the moment of inertia and reducing the impact of commutation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

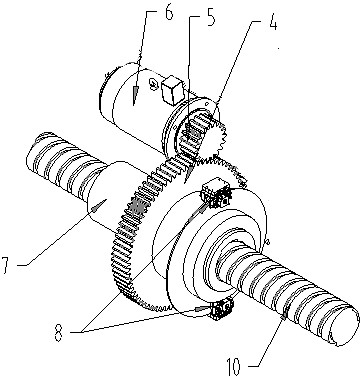

[0027] Such as figure 1 Shown:

[0028] S1, the brake B8 is closed, the screw nut B7 does not rotate, and the rotation of the screw B10 pushes the screw B10 forward;

[0029] S2. The brake B8 is released, the motor 6 does not run and can be reversely driven by the gear C5, the screw nut B7 will follow the rotation of the screw B10, and the screw nut B7 will decelerate in a straight line. When the rotation speed of the screw nut B7 and the screw When B10 is the same, the screw nut B7 does not move in the linear direction;

[0030] S3, the brake B8 is released, the motor 6 drives the gear C5 to rotate, the gear C drives the gear B to rotate, and the screw nut B7 turns in the same direction as the coaxial screw B10. When the screw nut B7 rotates faster than the screw B10, The screw nut B7 moves linearly in reverse, and the linear motion of the screw nut B7 drives the piston of the fracturing pump to move linearly and reciprocatingly.

[0031] As an optional implementation, dur...

specific Embodiment 2

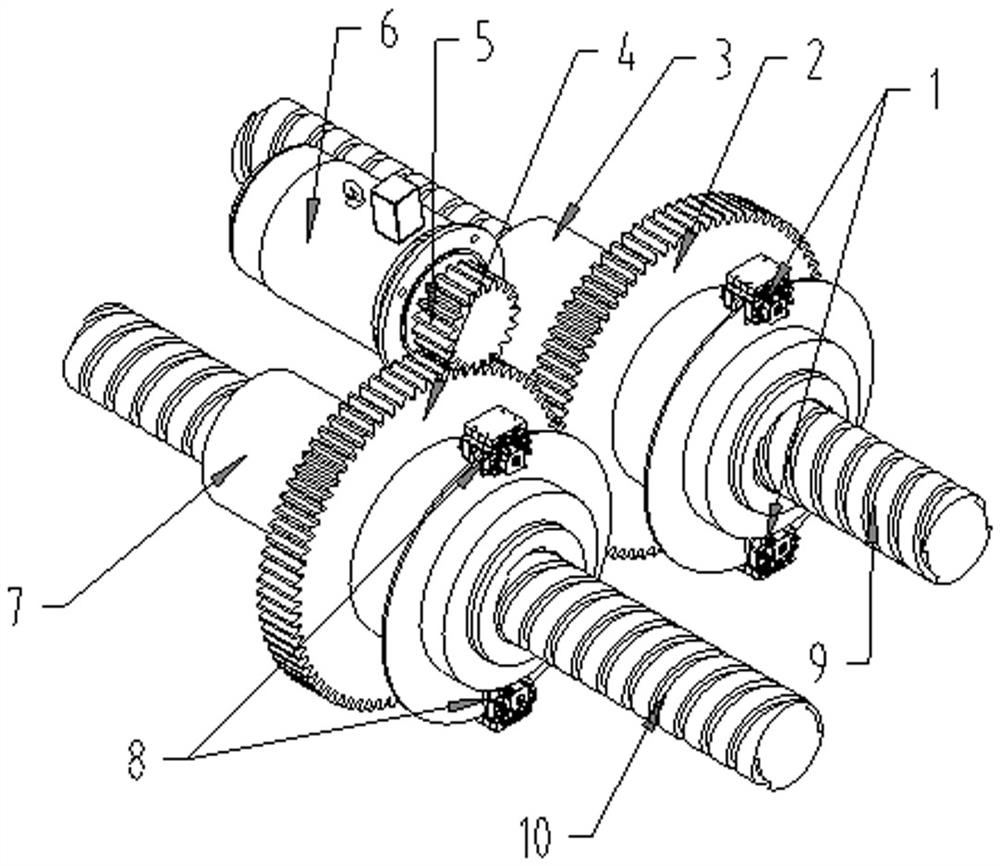

[0033] Such as figure 2 Shown:

[0034] S1, the brake A1 and the brake B8 are closed, the screw nut A3 and the screw nut B7 do not rotate, and the rotation of the screw A 9 and the screw B7 pushes the screw forward;

[0035] S2, brake A 1 and brake B8 are released, if the motor 6 is not running and can be reversely driven by the gear C5, then under ideal conditions, the screw nut will follow the screw to rotate until the rotation speed is the same as the screw, so that The screw nut decelerates in the linear direction. When the rotation speed of the screw nut is the same as that of the screw, the screw nut does not move in the linear direction;

[0036] S3. Brake A1 and brake B8 are released, motor 6 drives gear C5 to rotate, and then drives gear A2 and gear B4 to rotate, and at the same time, ensure that the rotation direction of the screw nut is consistent with the rotation direction of the coaxial screw, and when the rotation speed of the screw nut is higher than When th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com