Dual-chain drive pumping unit

A technology of pumping unit and double chain, which is applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc. It can solve the problems of difficult long stroke and heavy load, large reversing impact of pumping unit, low operating efficiency, etc. , to achieve the effect of long life, small commutation impact and large load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and example the present invention will be further described:

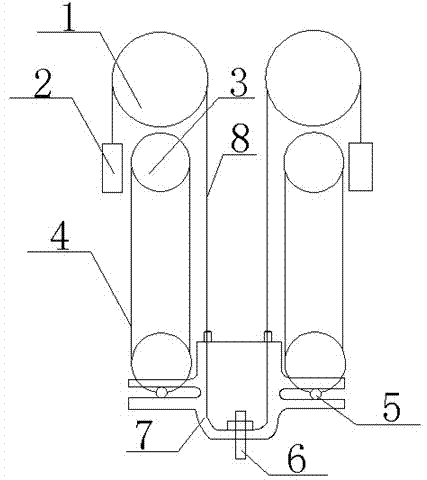

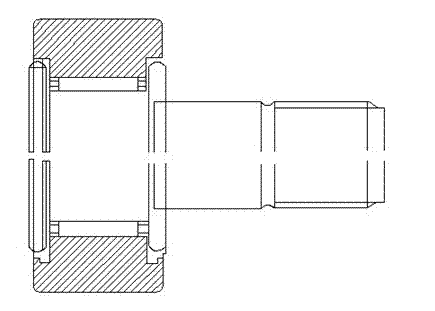

[0013] like figure 1 and figure 2 As shown, a double chain pumping unit of the present invention includes: reversing wheel 1, counterweight 2, sprocket 3, chain 4, bolt roller needle bearing 5, sucker rod 6, reversing frame 7 and steel wire rope 8. The steel wire rope 8 is laid on the reversing wheel 1. One end of the steel wire rope 8 is connected to the reversing frame 7, and the other end is connected to the counterweight 2. The lower surface of the reversing frame 7 is connected to the sucker rod 6, and the bolt roller The bearing portion of the needle roller bearing 5 is in contact with the commutator frame 7, and the bolts of the bolt roller needle roller bearing 5 are fixedly connected to the pin shaft of the chain 4, and the chain 4 covers the upper and lower sprockets 3.

[0014] Preferably, the commutator frame 7 is provided with a U-shaped groove, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com