Leakless plane type pure water electrohydraulic change valve

A pure hydroelectric, planar technology, applied in the field of hydraulic components, can solve the problems of application limitation, impurity jamming, increase processing difficulty and processing cost, etc., achieve good versatility, prevent cavitation, reduce cavitation and fluid noise. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

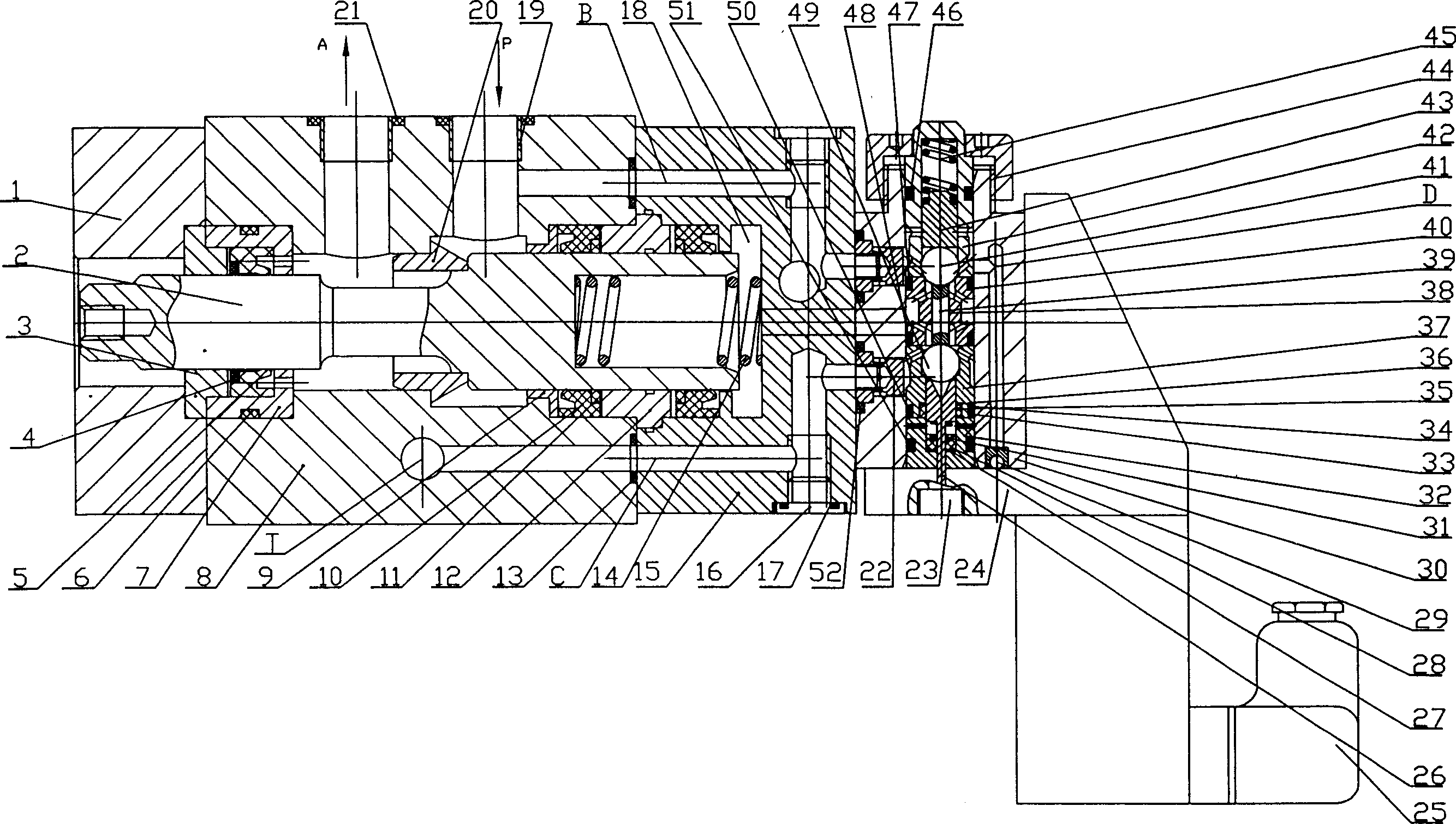

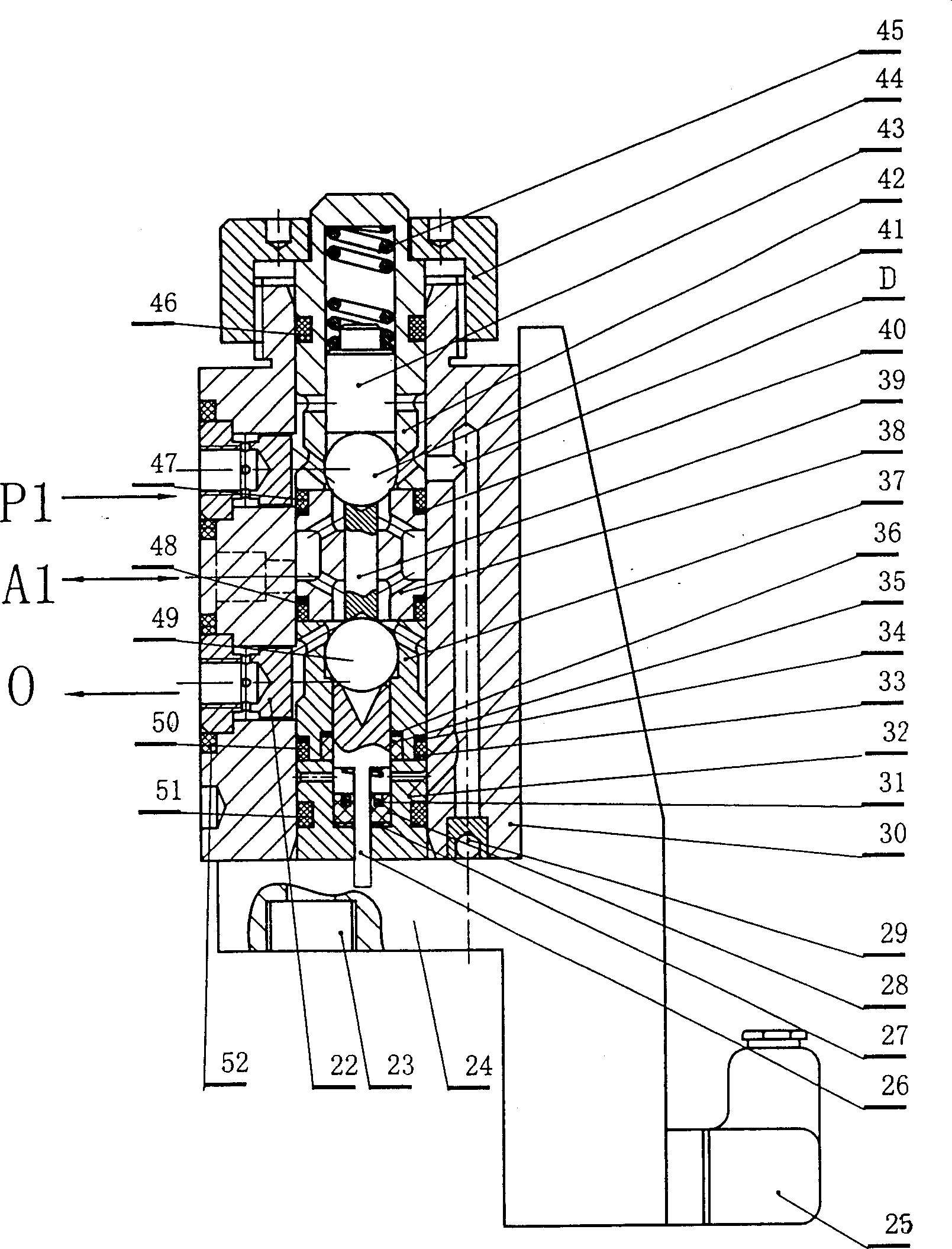

[0026] Such as figure 1 , figure 2 Shown, non-leakage plane type pure water electro-hydraulic directional valve, including:

[0027] 1) The planar main valve core 2 is installed in the left end cover 1, the main valve body 8 and the right end cover 15, the main valve sleeve 20 is installed in the center of the main valve body 8, and the spring 14 installed in the right end hole of the main valve core 2 will The outer shoulder surface of the valve core 2 is pressed against the end surface of the main valve sleeve 20, and the main valve sensitive cavity 18 is formed between the right end surface of the main valve core 2 and the hole 15 of the right end cover. The upper end of the main valve body 8 is provided with a water inlet P and a working port A. The two communicate with each other through the inner flow channel of the main valve sleeve 20, the water inlet P and the working port A are plate-type connections, and the left and right ends of the main valve core 2 are respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com