Hydraulic direct-drive vertical multi-cylinder mud pump

A mud pump and hydraulic cylinder technology, applied in the field of mud pumps, can solve the problems of complex reversing control mechanism, short service life of wearing parts, increased volume and weight, etc. compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

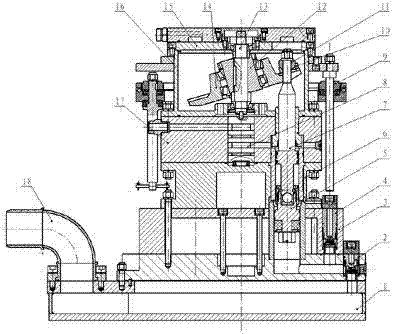

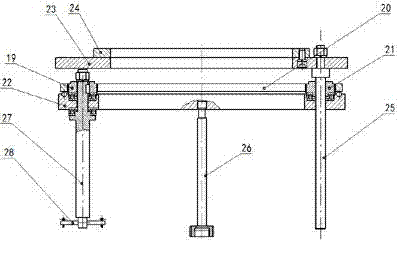

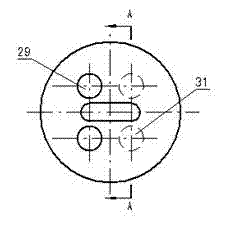

[0041] see figure 1 , 2, 9, the present invention comprises a water suction box 1, a drainage box 3, an oil inlet valve body 17, a hydraulic cylinder box 6, a lifting device 9, and the oil inlet valve body 17, the hydraulic cylinder box 6, and the drainage box 3 are stacked The formula structure is arranged on the upper part of the water suction box 1 in turn, and any two are connected by bolts and studs arranged in the circumferential direction. The upper part of the oil inlet valve body 17 is provided with a wobble box 16; A wobble plate 14 is set, the inclined shaft 12 is fixed in the middle of the wobble plate 14 through a pair of bearings, the pump shaft 13 set at the center of the wobble plate box 16 is connected with the inclined shaft 12 through a flat key, and the pump shaft 13 set at the center of the oil inlet valve body 17 The o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com